The art of fine-tuning an engine computer is viewed as one of the blackest in the aftermarket. Table after table of arcane numbers, weird figures, lambda this, AFR that, boost pressure the other...it's enough to make one's head spin. However, it's also a necessary step in squeezing the last drops of performance from an engine.

If your engine is equipped with just an intake and exhaust system, you don't really need an aftermarket computer. Sure, it would help, but your money can be spent on many other things before a computer is needed. However, if you have turbocharged your naturally aspirated engine, have seriously tweaked the internals, or are running a monstrous nitrous oxide system, then a programmable engine computer is a necessity.

And AEM has a little surprise for you.

The company's just-released Programmable Engine Management System (PEMS) has a somewhat lackluster name. No verbal fireworks there, no "Fireball Super Programatron" or anything like that. But that's fine with us, because it is what's contained inside the little aluminum box (and on the CD ROM that comes with it) that makes us salivate. In short, AEM has made engine computer programming easy.

Now, there are a few caveats. When we say "easy," we mean relative to other engine management systems. If you don't know which way to turn a screw to tighten it, this is way out of your league. In fact, even if you're a pretty competent wrench, you should think twice about tinkering with your computer. Even with AEM's simplified software, you can still seriously damage your engine, and a dire warning about reducing your engine to pretty aluminum shrapnel prefaces all of the manuals that come with the software. Tinkering with your car's brain is just as dangerous as it has ever been. In other words, throw your ego out the window. If you feel the least bit uncomfortable doing this stuff by yourself, take it to a pro. If you don't, and you blow your engine to smithereens, well, you've been warned.

With all the dire warnings out of the way, we can say that AEM has reduced the difficulty level from, say, the double diamond of an expert ski slope to the single diamond of advanced. If you know air/fuel ratios, spark timing, MAP sensors and can judge an engine's health by looking at them and how they affect dynamometer results, then you should be able to effectively use the PEMS, after reading the manual thoroughly, of course. If you're already familiar with other systems, you will find the AEM system that much easier to manipulate and use.

Describing every single function of the PEMS would take volumes. In fact, it does. Included on the installation CD are Adobe PDF files for setting up the system, using it, programming it, etc., and the system comes with a manual thick enough to make the most prolific novelist blush. Luckily, it's written less like Tolstoy and more like Clancy. Briefly, the system features a fast Motorola 16/32 bit processor, plenty of memory for on-board datalogging (more than an hour's worth depending on the sample rate), and expandability for use with nitrous oxide, forced induction or anything else you can imagine. So, while we can't cover every single aspect of the system in a four-page article, we can give you a demonstration of how the software works, how flexible it is, and how quickly you can make results happen.

One of the strongest selling points of the system is its ease of installation. The end user does not need to build the wiring harness. The exception is for the PEMS Race system. Designed for those double-diamond users, the Race system doesn't include any pre-loaded software, and doesn't come with a pre-built wiring harness. However, it should be noted that those are the only differences between the Plug & Play and the Race systems. Functionally, they are identical.

For most applications, however, AEM uses a factory wiring harness, and utilizes all of the factory sensors. This means that installation is reduced to simply uncovering your stock computer, unplugging and removing it from the car, and plugging in the AEM computer. Obviously, it's important not to yank or cut any wires out of the stock harness, but the physical installation shouldn't take more than just a few minutes. Compare that with the tedium of building a harness from scratch, or as is sometimes the case, tapping and drilling the engine for new non-stock sensors. And don't worry; if you have modified your car and have additional inputs, the Plug & Play system can accept them without a problem.

The AEM Pro software installs on any PC--preferably a laptop, since most of the programming will be done in the car--that is running Windows 95, 98, Me, NT, 2000 or XP. You will also need a serial cable to connect to the PEMS itself. Note that if your computer is equipped only with USB, a USB-to-serial converter will work, and AEM is working on USB connectivity for a future release. (Mac users should note that although the software runs just fine under Virtual PC from Connectix, we did not have the opportunity to connect it to the computer, yet we see no reason why it shouldn't work.)

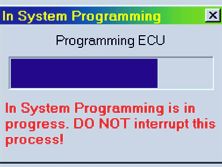

The Windows-based software is already an improvement on systems that run in DOS. Installation is quick, using wizards and the other handholding techniques developed by Microsoft. Once installed, you are presented with the ECU Setup Wizard. You select your make, model, year, transmission and which units (English or Metric) you want to use. The AEM Pro software then selects your vehicle's basic map from its database, and proceeds to download it to the PEMS box (provided, of course, you're connected to it).

Once up and running, you will find a basic map for your car. It's not optimized in any way, and if you have performed extreme modifications, such as turbocharging a naturally aspirated car, it will barely work at all; it might idle properly, but that's about it. However, it is a jumping off point for tuning your engine properly, and, it's a hell of a lot better than starting from scratch.

With everything installed and the software happy, it's time to start programming. The software is flexible enough to accommodate virtually any extra inputs. The computer itself comes with 104 pinouts, far more than the wiring harness on most cars. So, if you have in fact turbocharged your Integra, you can still program boost control, an extra fuel injector, an auxiliary fuel pump, or whatever else you have connected to your engine through the PEMS, rather than through external controllers.

However, you can still use the external controller if you like. In addition, you can program different maps for different conditions, and switch between them. You can even trigger a shift light and other goodies through the system. If you have an automatic transmission, the PEMS can control shift functions as well, with "hard" and "soft" maps for racing and cruising, respectively. In fact, according to Jason Siebels--one of the chief engineers responsible for the PEMS--they have only been tripped up once on the PEMS' abilities, and it was for something so ludicrous it wasn't even worth doing. But rather than review every single function the system is capable of, we are going to concentrate on the two most basic elements of engine tuning: fuel delivery and ignition timing. And for our test vehicle, we selected something that would properly demonstrate the system's capability.

Our test car already had the PEMS installed, so our goal was to further tune it and turn up the boost. The '95 Civic coupe owned by AEM's Jeremy Powell was equipped with a B18C1 engine with a Type R head, a Drag Stage 3 turbo kit (with a Garrett T3/T4 hybrid turbo), bigger 450cc injectors, an AEM fuel rail, stronger fuel pump, etc. With the exception of a leaking seal on the turbo itself, this was already a well-sorted machine, with plenty of dyno time under its belt.

We strapped the car to the DynoJet at Gardena, Calif.-based R&D Dyno. Our first pull netted us a healthy 260 horsepower at the wheels. However, the car was unexpectedly running dangerously lean (more than 15:1) as boost built up to its maximum 11 pounds.

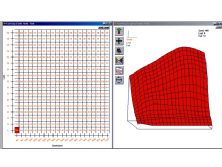

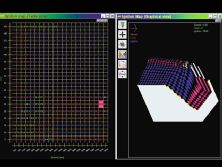

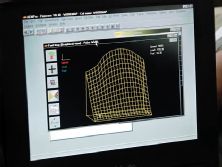

Siebels hooked up the laptop and went to work. He uploaded the ECU's current state to the laptop, and opened up the fuel map graph. But instead of manually renumbering each cell on the table by hand, he simply clicked on the edge of the graph and dragged it higher, thus telling the computer to add more fuel at that range. He did this at several points along the graph. Then the magic of the software came into play. Siebels did not need to adjust the rest of the table--or even the graph--by hand. Instead, he simply selected an area and commanded the software to "smooth" out the graph for all the points selected. The whole procedure took about a minute. For other systems, that would have been a solid half hour of work.

The car was fired up, and Siebels laid down another dyno pull. Still lean, but better. A few more tries showed the big injectors were nearing the limit of their duty cycle, which by all logic should have been flooding the cylinders with gas. Clearly there was a problem with fuel delivery, and a quick glance under the hood discovered that the power lead for the secondary fuel pump (supposed to come on at 3000 rpm) had come loose. The fuel map was returned to the original settings via the "undo" button, and tuning started from scratch. This particular problem was detected, diagnosed, and fixed within about a 30-minute span.

This time, the engine was much happier, and had plenty of gas. So the boost was turned up (in this case, through an external boost controller). After a couple of steps, the boost was comfortably raised from 11 pounds to 13. Fuel was increased appropriately, and a solid 12.5:1 ratio was shown through the full pass. At this point, the car was just breaching 300 hp at the wheels.

Just for fun, we tried a little experiment. The VTEC threshold was moved from 5500 rpm (where it was producing an almost imperceptible bump in the power curve) down to 5000 rpm. This produced a dramatic difference, with a weird hiccup forming at the VTEC switchover, clearly not ideal. When moved 500 rpm in the other direction to 6000 rpm, the opposite happened. A step formed at the crossover, another undesirable characteristic. Leaving it at 5500 rpm was clearly the best alternative. With the boost and fuel-air mixture taken care of, it was time to manipulate the spark. Siebels selected a range in the spark map and advanced the spark by three degrees, good for another 10 horsepower. A quick change to 6 degrees of advance showed no advantage, so the computer was dialed back to 3 degrees, and the final program was downloaded to the ECU.

With a half hour of actual tuning behind us (that doesn't count the time spent dealing with the faulty fuel pump), we were able to net an additional 50 hp out of two pounds of boost. What would have taken at least an entire afternoon with a fast programmer in a different program took less than a lunch break.

As remarkable as this is, it only scratches the surface of what the new computer can do. The system isn't dumbed down, but smarted up, if you will. It's easier to use not because of a lack of features, but because the features are better thought out. AEM says in its advertising that "the revolution has arrived." We're forced to admit that claim isn't far off the mark.

SOURCES

Advanced Engine Management, Inc.

(310) 484-2322

www.aempower.com