In annual Readers’ Rides issue tradition, I’ll once again be waxing eloquent about suspension tuning, but instead of worrying about super-low ride heights and suspension geometry or hellaflush wheel fitment and camber curves, we’re going to take a closer look at the inner workings of the most important part of your suspension: the shock absorbers.

|

Putting A Damper On Things - Tech Talk

|

Putting A Damper On Things - Tech Talk

But before we take a peek inside the automotive damper, and in particular examine the pros and cons of mono-tube and twin-tube shock absorber design, let’s quickly review what exactly a shock’s job is and how it goes about achieving it. At its most basic level, the shock absorber or damper is designed to absorb and dissipate energy, specifically to dampen or reduce spring oscillation. To visualize a shock absorber’s function, imagine a coil spring being compressed and all the stored energy this represents. Now imagine that spring uncoiling; without a damper to control all this stored energy, you’ll have a serious pogo-stick situation on your hands, causing your car to literally bounce down the road. So it’s the shock absorbers that smooth out all those bumps in the road, by converting the kinetic energy generated by the suspension and associated unsprung mass (brakes, hub, wheel and tire, etc.) as it moves up and down over bumps.

In the case of modern hydraulic shock absorbers, heating up the viscous fluid and compressing the nitrogen gas inside the shock body is what absorbs and dissipates the kinetic energy generated during suspension travel. The oil in the shock is heated during a compression event (the suspension moving upward over a bump), where the shock piston and attached valve shims are pushed down into the shock body, forcing the fluid through orifices in the valves. This generates heat within the fluid, which is then dissipated to the shock body, where it can be transferred to the ambient atmosphere. The same heat generation, absorption and dissipation process happens in reverse on the rebound stroke, where the suspension travels back to its neutral position after encountering a bump.

|

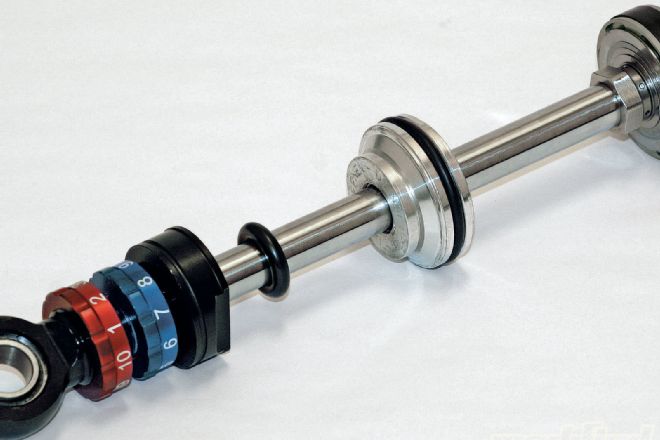

A side-by-side comparison of mono-tube (left two elements) and twin-tube (right three elements) clearly illustrates the larger surface area of the mono-tube piston and valve shims.

|

A side-by-side comparison of mono-tube (left two elements) and twin-tube (right three elements) clearly illustrates the larger surface area of the mono-tube piston and valve shims.

In a nutshell, that’s how a shock absorber works, but when it comes time to upgrade your dampers to something better able to handle those weekends on the autocross course, racetrack or your favorite twisty bit of backcountry road, what should you be looking for when it comes to design and construction? More specifically, what are mono-tube and twin-tube designs and what are their relative pros and cons? To answer these questions, enter Bret Norgaard, product engineer at Bilstein and a genuine enthusiast and accomplished racing driver.

Starting with mono-tube dampers, Bret explains, “A conventional mono-tube damper is based on a single hydraulic cylinder design that incorporates a ported working piston with deflective valve shims to govern oil flow, a secondary floating piston and an inline high-pressure gas chamber. This type of damper design can be tuned with high precision due to the large surface area of the piston and valving shims. The nitrogen chamber pressure is a key element to this design. It prevents oil cavitation (foaming) and offsets changes in volume do to thermal expansion. Being that the nitrogen chamber is completely isolated from the oil by the dividing piston, a mono-tube damper can be mounted to a vehicle inverted (body-up) and maintain its damping performance. The mono-tube design has precise tolerance requirements that lend to its precise damping control, durability and long-term performance. This is in part why high-end motorsport dampers are based on this design, as is the fact that they’re also rebuildable and retunable to meet customer-specific needs [and explains why this design is used in the vast majority of Bilstein’s product line].”

|

This cutaway of a mono-tube damper reveals the ported working piston and shim stack bolted to the base of the piston shaft, as well as the secondary floating piston near the bottom that creates a separate high-pressure gas chamber.

|

This cutaway of a mono-tube damper reveals the ported working piston and shim stack bolted to the base of the piston shaft, as well as the secondary floating piston near the bottom that creates a separate high-pressure gas chamber.

By contrast, according to Bret, twin-tube dampers cater more to mass production and lower cost (due to its simpler construction and looser construction tolerances), but they do give up some performance as a result. “The twin-tube damper design is comprised of a small-diameter cylinder tube within the visible outer housing tube. A comparatively small working piston is attached to the shock shaft that reciprocates inside the inner cylinder tube,” Bret says. “A base valve is located at the bottom of this tube and this is where the damper is tuned. The base valve function relies on fluid displacement from the piston shaft and working piston, forcing the oil through the valve and into the outer cylinder.

|

As you can see from this cutaway of a twin-tube damper, the working piston is housed within the smaller diameter inner tube, reducing piston surface area and therefore damping control and sensitivity.

|

As you can see from this cutaway of a twin-tube damper, the working piston is housed within the smaller diameter inner tube, reducing piston surface area and therefore damping control and sensitivity.

“The oil that is forced through the base valve can be regulated by several methods. Small deflective shims, variable ports or spring valves can be used to govern the flow in either direction through the base valve. The mechanical function is similar to the mono-tube, but the available surface area for high-performance tuning is substantially less. Some twin-tube dampers will have a low-pressure gas charge added to the oil cylinder to displace the oil slightly. This is called an emulsion damper (gas/oil mix) and damping performance can be adequate for a street car, but as shaft speeds and temperatures increase, the twin-tube damper performance will degrade. Gas rises in the shock oil and therefore a twin-tube damper must not be mounted to a vehicle inverted. The gas must stay within the outer chamber toward the top of the strut body. If inverted, the gas will transition to the area around the base valve and defeat the dampers function.”

So when you go shopping for that sweet new coilover setup for your weekend track car or canyon carver, be sure to determine if the shocks are a mono-tube or twin-tube design. Price is an important consideration, but if you’re willing to pay a little extra for all the performance advantages of a mono-tube design, it’s clear based on Bret Norgaard’s assessment that it’s an investment worth making.

Send your feedback to dpratte@modified.com

|

Putting A Damper On Things - Tech Talk

|

Putting A Damper On Things - Tech Talk