But our resident B-list MTV celeb Greg Leone has finally scraped together enough parts and put aside enough time to proceed forward and complete the cage, as well as get the suspension mounting points dialed.

The most important aspect to designing and building a suspension is planning. Planning ahead can make or break your suspension project. Among the many things you need to consider before shopping (and ultimately building) are: What kind of driving will your suspension see (drift, grip, circuit, street, dirt rally, drag)? How much travel will the suspension need? Will you need adjustability and the ability to change settings? If building for a race class, are there limitations in the rules? Are the A-arm mounting points reinforced and strong enough?

Building a suspension is a never-ending compromise. For instance, a drag car's suspension settings and geometry are completely different from a road racecar. To have a car that can do both on the same setup would sacrifice performance in both disciplines. If you need a car to perform a dual role you must design those parameters into the initial setup (for example, making different mounting points for the A-arms, quick-change spring rates, etc.).

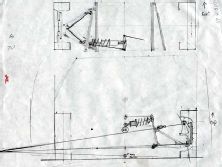

Our project is designed with two goals in mind: to be a road racecar that will do 1:20 at Willow Springs and to tackle the various drift courses that are popping up around the country. Two completely different setups. A road racecar is best served with neutral handling characteristics, achieved using a stiff front sway bar and softer rear springs. A drift setup would see a stiffer spring in the rear and almost no front sway bar. Additionally, the dampening and rebound settings would change, as well as some suspension geometry and mounting points. To design a successful suspension it is a good idea to first look at what is winning out there in the real world. Many design principals have already been heavily tested and improved upon over the years. Venturing off the beaten path of what's proven may turn out to be time consuming and futile unless you really know what you're doing.

It's not that uncommon to have trouble finding the right parts when building a racecar. But when building an anomaly, more often than not parts are more elusive than a 10-second quarter-mile time slip in a Geo Metro. In fact we're willing to bet that many a stalled racecar project out there is likely the victim of one little critical part that the owner just hasn't been able to find.

The parts hunt started for us with the hubs and knuckles. The hubs should be the focal point in your suspension project. The NSX came with aluminum knuckles and a rear-drive configuration that were a must to keep the unsprung weight (the weight of the wheels, tires, knuckles, hubs, and about half of the shock and A-arm weight) to a minimum. These parts were located in Brooklyn, N.Y., at ERZ, an exotic car wrecking yard where the donor NSX wouldn't be needing them anymore.

Next is the wheel and tire package (see photos on previous page). After measuring the fender-to-wheel clearance, it was decided a 17x9.5-inch rear wheel would fit. A deep negative offset wheel was desired, but due to the latitudinal configuration of the motor/transmission the knuckle wouldn't have cleared the chassis. A conservative +38 offset was chosen instead. Enkei's new RPF-01's were selected because of their light weight and hard-to-find 17x9.5 configuration. The front wheels are 16x7 with a 42 offset.

Tires, like suspension setups, change with each different application. The Toyo RA-1 275/40-17 stickies are used for grip driving and the Toyo T1's are used as a drift tire because of their greater treadware and ability to handle more heat. Toyo 225/50-16 RA-1's were the call up front, and Big O Tires in Anaheim, Calif., oversaw the union of wheel and tire.

Shocks are our next focus. The problem we had was finding an eye-to-eye shock within our budget (which was zero) that would fit all our requirements. We were about to give up and start scheming up a three-cylinder Geo Metro turbo kit when we learned that Tein makes a 21-way adjustable short throw eye-to-eye shock perfect for a custom suspension.

The chrome-moly rod ends were obtained from H&M Bearings in Fountain Valley, Calif. Threaded tube inserts, jam nuts, rod end spacers, and gussets were obtained from Pro-Werks, a good source for fabricators and chassis builders. Playtech Fabrication has the tabs on the tabs, all precision laser cut and ready to save you hours of headaches trying to make your own.

Hoerr Racing Products is the only company we have ever found to manufacture an adjustable sway-bar blade. The blade comes in kit form complete with an aluminum cockpit adjustment lever. The blade works on the principle that when it is flat it is most flexible (soft setting) and when it is vertical it is stiffest (hardest setting). Finally, after the painstaking task of acquiring all the necessary components it was time for the easy part - putting it all together.