| 1996 Nissan 240SX SE Suspension Test - G The Factor

| 1996 Nissan 240SX SE Suspension Test - G The Factor

Import Tuner goes in search of extreme Gs as we test our Nissan 240SX on the Skid pad and the racetrack in stock configuration. Then we install a high-quality suspension package and dare to compare the test results.

The Car

Our test car is a well-used, but not abused, 1996 Nissan 240SX SE. We started out this "canyon carver" transformation with our test-mule in totally stock configuration to get firm baseline numbers. It's always a good idea to minimize the variables when performing tests of this nature, so we decided to carry out our tests on a racetrack and skid pad, and we also decided to employ the services of a professional driver.

Our choice of racetrack was a no-brainer. The Motorsports Ranch is a first-class facility located about 15 miles south of Fort Worth, Texas, and is a firm favorite of road racers in the Southwest. The track is a 40-ft-wide, 1.7-mile torture test for the chassis and brakes, and features a wide variety of turns and elevation changes. The combination of flat-out high-speed straights and very technical sections demands the most from the car and the driver. Track knowledge is, as is the case at most racetracks, very important and total precision is the key to setting a decent lap time.

| 1996 Nissan 240SX SE Suspension Test - G The Factor

| 1996 Nissan 240SX SE Suspension Test - G The Factor

We turned to pro-racing driver Jeff "Hound Dog" Harrison to provide the skills to test our 240 at the limits of adhesion, and more importantly, to give us the feedback we needed to maximize the potential of the S14 chassis. Jeff has extensive experience in a wide variety of cars and has raced on many tracks in the United States and Europe with great success. This experience is an invaluable asset when searching for the last 1 percent from a car without actually pushing it too far. The last thing we wanted to do was trash our daily-driver 240, but we did want to push the limits as far as possible. Jeff would not disappoint us!

Test 1: The Skid Pad (stock)

The skid pad is without a doubt the best place to measure a car's lateral performance. We opted to use the 200-ft diameter pad at the Motorsport ranch. Before Jeff started the test session we double-checked the tire pressures and gave the car a last minute check-over.

| 1996 Nissan 240SX SE Suspension Test - G The Factor

| 1996 Nissan 240SX SE Suspension Test - G The Factor

From the sidelines, Jeff's first few laps were spectacular if nothing else. Our 240 was obviously way too soft and body roll was extreme. As Jeff built up his speed the tires howled in protest, and the inside rear tire struggled to stay on the pavement. Jeff was busy making minor steering corrections and throttle inputs in an effort to keep the car in shape. When he pulled in we made our calculations and were surprised to see that our test mule had pulled 0.86g in a counterclockwise direction.

Jeff gave us his initial impressions: "The car is heavily undersprung and the sway bars are almost ineffectual, causing it to understeer pretty badly. It's a pretty good chassis, though, and once the car is settled it's fairly easy to hold a line using the throttle. The stock tires are obviously a limiting factor, but overall I am impressed with the car's capabilities."

We ran the same test again in the opposite direction and ended up with a 0.85g result. We then played around with the tire pressures with no improvement at all, so we settled for a very reasonable 0.86g.

Test 2: The Race Track (Stock)

We really didn't have high expectations as we headed over to the Motorsports Ranch road course, but we told Jeff to drive as hard as he could without sticking his neck out too far. Jeff pulled out onto the circuit and ran a couple of warm-up laps before he got serious and put the pedal to the metal.

| 1996 Nissan 240SX SE Suspension Test - G The Factor

| 1996 Nissan 240SX SE Suspension Test - G The Factor

One of the things you notice about top-class drivers is that they seem to be totally effortless at speed. Jeff looked very smooth, and watching the car in the turns it was obvious that, despite the soundtrack (screaming tires and wailing engine), Jeff was totally under control. The end of the first hot-lap stopped the timer at 1:36.88, with an average speed of 63.17 mph. The second lap was a little better at 1:36.50. Jeff then rolled into the pits and gave us some feedback: "I wasn't really pushing too hard on those laps, I wanted to get a feel for the car. The first thing I noticed is that it understeers badly on the initial turn-in. Once it settles down it's pretty good and seems to hold the line pretty well, but overall it feels very soft and squishy. The tires are a major limiting factor again and the brakes start to fade after a couple of laps. I reckon I could go a lot faster with better brakes."

We sent Jeff out again with instructions to push the car as hard as he felt comfortable with. Jeff responded with a very credible 1:36.33 on his first lap. The next lap saw him break into the 35s with a 1:35.98 at an average speed of 63.76 mph. On the third lap Jeff slowed considerably and rolled into the pit-lane with smoke billowing out from behind the front wheels.

"No brakes," he said. "They just faded away to nothing on that lap, and it's obvious we'll have to do something about it before we come back again. Also, the engine feels a bit sluggish. It's a little bit unresponsive to throttle input."

| 1996 Nissan 240SX SE Suspension Test - G The Factor

| 1996 Nissan 240SX SE Suspension Test - G The Factor

These comments just confirmed what most 240 owners are already aware of. The stock brakes are pretty puny and are generally upgraded at the earliest opportunity, and the 2.4-liter KA24DE is more of a torque motor than a high-revving speedster.

Once we cooled off the brakes and gave the car another check, "Hound Dog" headed out for one more try. We just told him to go for it and to hell with the consequences.

The final session saw Jeff doing a Texas-Two-Step on the ragged edge of adhesion. The car was starting to get a little out of shape, but Jeff still managed to post the best time of the day, a 1:35.69 sec e.t. with an average of 63.95 mph.

The Parts

Now it was time to decide what we could do to convert our S14 from pseudo-sports car to a razor-sharp canyon carver. I sat down with Kyle Thurber, owner of CTC Motorsports in Dallas, and we formulated a plan of action. We decided that although we didn't want to make our S14 a track-only car, we could still use high-quality parts with a racing background. The Nissan Silvia/240SX platform has a huge following in Japan, so it made sense for us to try to use as many Japanese-developed parts as possible. We compiled a list, I got busy on the phone, and we got our parts on the way.

| 1996 Nissan 240SX SE Suspension Test - G The Factor

| 1996 Nissan 240SX SE Suspension Test - G The Factor

Wheels And Tires

It was obvious from our tests the car desperately needed a lot more rubber meeting the road. To make this possible we needed to find a set of wider wheels. Weight was obviously a major consideration, so we called Alex Chung at 5Zigen USA to see what options we had. Alex (a 240SX driver himself) pointed us in the direction of 5Zigen's FN01-R Beckett racing wheels. These rims are forged in one piece for maximum strength and minimum weight (our wheels weighed in at a scant 15 lb each). We decided that we would install 17x9s in the rear and 17x8s up front. We knew that we would be installing a bigger brake package on our car, but Alex assured us the offset at 40mm would clear pretty much any system we installed (and he was right). We decided that a white finish would look good on our red 240, and Alex sent the wheels on their way.

| 1996 Nissan 240SX SE Suspension Test - G The Factor

| 1996 Nissan 240SX SE Suspension Test - G The Factor

Tire choice was a little more difficult. Just about every tire manufacturer offers high-performance tires. We decided to trade a little longevity in the interest of maximizing traction, and our final choice was the Toyo Proxes-RA-1. The RA-1 is primarily designed for road racing and autocross, but it is DOT approved for street use. The directional-tread design, carcass and rubber compound are all developed to give as much directional stability and traction as possible. We talked to Greg Vandermark at Toyo and he suggested that a 255/40ZR17 would be ideal for our 9-in. wheels and the 235/40ZR17 would be best on the 8-in. front wheels.

Suspension

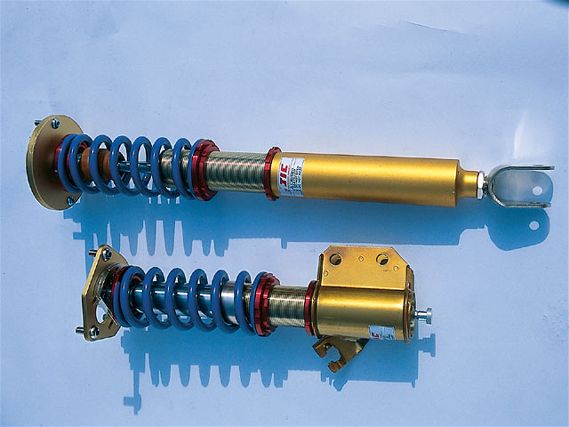

This is one area in which we decided to pull out all the stops. After researching our options we decided JIC Magic was the way to go. JIC is a Japanese manufacturer with a superb reputation for building high-quality suspension components. We called the U.S. importers, Zeal Motorsports, and talked to technical guru Terry Henderson. We explained exactly what we were looking for and Terry suggested a set of JIC FLT-A2 coilovers might be just the ticket. The FLT-A2s are top-quality pieces of equipment that are designed for maximum performance ,while still remaining easy to live with on a day-to-day basis.

| 1996 Nissan 240SX SE Suspension Test - G The Factor

| 1996 Nissan 240SX SE Suspension Test - G The Factor

The 15-way adjustable shock uses special oil and nitrogen gas to stabilize the performance over a wide range of temperatures, and the shock body is fully threaded to allow strut height adjustment without affecting spring-perch location. What this means is the FLT-A2 allows complete suspension travel at any ride height.

The progressive springs are cold-drawn silicone steel and are available in just about any rate (with Terry's guidance we decided on 8k springs front and 6k rear) and the spring perches are manufactured from Duralumin 6061 for strength and weight savings.

The FLT-A2s also come complete with beautifully machined pillow-ball top-mounts. The front mount is fully adjustable to allow fine-tuning of the camber angle, essential when lowering a car. Camber adjustment also allows you to dial in the tires' contact patch for different tracks conditions. The top mounts are gold anodized and look absolutely awesome. All the rest of the shock components are anodized or cadmium plated to resist corrosion and keep the JICs looking good.

Having settled on our shocks, Terry suggested that we also install a set of JIC adjustable rear upper A-arms to allow us to adjust the rear camber. The A-arms are manufactured from tubular steel and feature a fully adjustable spherical bearing, which not only allows the camber to be tweaked but also eliminates the sloppy stock rubber outer bushings. JIC also offers a very trick Pillow tension rod that locates the front suspension to the chassis. Using the adjustment of the rod allows the caster angle to be precisely set and, with its massive spherical bearing replacing the stock rubber bushing, steering feel is vastly improved.

Finally, Terry aimed us at a set of JIC Magic front and rear strut-tower braces. Once again, quality is the key word here. The front brace is manufactured from highly polished D-section aluminum tubing for strength and clearance, and the rear brace (which installs on top of the rear parcel shelf) is built from round tubing. Both braces have nicely manufactured brackets that bolt onto the shock mounts, and like all of the other JIC components the brackets reek of race-tested quality and attention to detail.

| 1996 Nissan 240SX SE Suspension Test - G The Factor

| 1996 Nissan 240SX SE Suspension Test - G The Factor

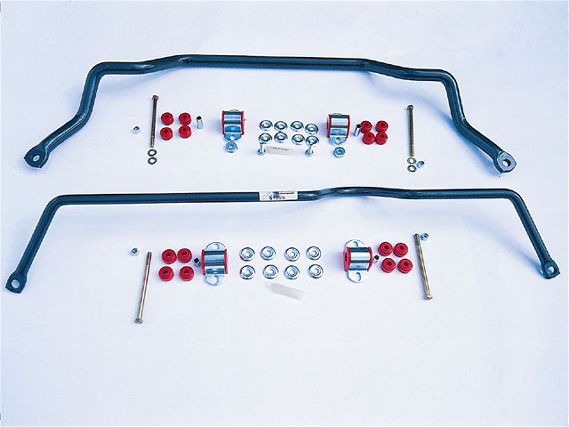

My next call was to anti-sway bar manufacturers, Suspension Techniques. We desperately needed some help taming our 240's inclination to attempt to grind the mirrors in the turns, and ST was happy to help. Our SE model 240 came equipped with front and rear anti-sway bars, but in extreme situations the stock bars are not quite big enough for the job in hand. The front Suspension Techniques bar is 1 1/8-in. thick and is 22 percent stiffer than the stock 27.2mm bar. The rear bar is 13/16-in. thick and provides a colossal 182-percent increase over the puny stock 15.9mm bar. Our bars came equipped with all necessary mounting hardware, including urethane bushings.

The Brakes

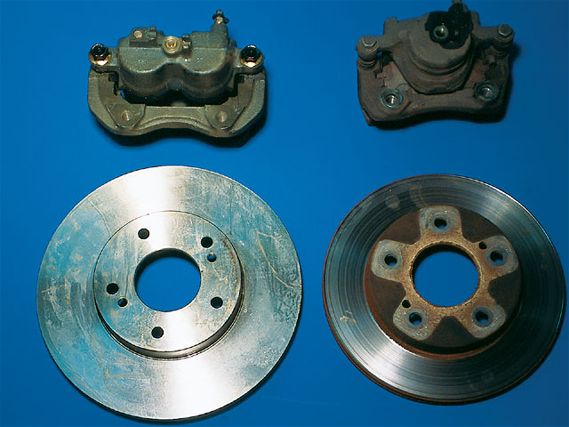

It was obvious from our track tests the stock 240 brakes would be a limiting factor in the canyons. The last thing we needed was to find ourselves brakeless after a spirited driving session in the hills, so we decided to upgrade in search of better fade resistance and overall performance.

| 1996 Nissan 240SX SE Suspension Test - G The Factor

| 1996 Nissan 240SX SE Suspension Test - G The Factor

We called the ever-helpful staff at Courtesy Nissan in Richardson, Texas, and talked to parts manager Steve Richardson. Steve proved to be a veritable mine of information, and after listening to our tales of woe he was more than happy to supply the parts that would solve our problem.

As one of the largest Nissan Motorsports dealers in the country, Courtesy had everything we needed on the shelf. Steve disappeared into the vast parts warehouse and reappeared 10 minutes later with our parts.

The 240SX brake upgrade that Steve appeared with is a genuine Nissan upgrade, featuring parts sourced from the Infiniti Q45 luxo-barge. The discs are 280mm in diameter and 28mm thick, as opposed to our stock 252mm and 20mm O.E. rotors. With directional cooling veins and the extra material in the new discs, overheating should not be a problem as it is with the stock setup. The kit also included a set of calipers with dual 42.8mm pistons (stock is a single 54mm piston) and a set of pads that give an increase in effective area of more than 40 percent.

While we were at it, we decided it would be smart to install a set of Goodridge braided steel brake lines, and we also bought a bottle of high-performance AP brake fluid. Once again, these products were all available from the warehouse at Courtesy Nissan.

Other Stuff

We decided to try to liven up the KA24DE powerplant with the help of a lightweight flywheel. With constant gear changing up and down the box, a lightweight flywheel definitely makes life easier. Engine response to throttle input is greatly increased, and overall this is one of the best mods to make to the KA if you're in search of more performance.

We called the crew at Indigo Speed for our aluminum flywheel. Indigo has been manufacturing high-quality aluminum components, including flywheels, pulleys and radiators, since 1997 and has established a reputation for producing top-quality parts. The Indigo Speed flywheel is CNC machined from T6061 aluminum and fitted with a changeable steel friction surface. The steel ring-gear is heat shrunk in place, and the total package weighs in at less than half the weight of the stock cast-steel flywheel.

While we were changing the flywheel it made sense to upgrade the clutch to withstand Harrison's (and possibly my) abuse. Advanced Clutch Technologies (ACT) had a performance upgrade that was perfect for our application. Our stage two clutch came complete with a new thrust bearing, pressure plate and disc rated at 275 lb-ft of torque, more than enough for our mostly stock KA24DE.

So, what's the result of all this planning? Tune in next month as we install our chosen aftermarket parts and put them to the ultimate test.