|

| Somewhere there's a perfect balance between peak horsepower, low-speed response, reduced emissions, and something you can afford. Variable valve timing and lift have done their part in getting us all closer to that. Nothing affects an engine's behavior more than its cam profile. On otherwise equal engines, for example, something as singular as a cam change can turn an otherwise low-RPM brute into a hyperactive, high-revving dickens. But not both. Before variable valve timing, compromises had to made, and almost always sacrificed the torque for the high-RPM high jinks until an acceptable compromise between the two could be achieved.

Twenty-five years ago, variable valve timing was considered exotic technology. Today, almost every automaker uses it on even their most entry level of econo-buckets. And although Honda evangelists might have you believe that VTEC is the first and last word on the matter, the engineers at Nissan have been dabbling in the technology responsible for dynamically altering valve events for just as long and with just as many iterations.

VCT

It all started in 1987 with Nissan's Variable Camshaft Timing—the VCT namesake—which dynamically adjusts cam timing throughout the powerband but has since been entirely phased out. Right about now you might be thinking that 1987 happened a whole two years before 1989, which is when Honda introduced VTEC on its second-generation Integra. Trouble is, Nissan didn't necessarily promote its whole variable cam phasing architecture as effectively as Honda did with its, which makes forgetting the fact that it came first forgivable and easy to do.

Also known as NVCS (Nissan Valve Timing Control System) in some circles, here, duly equipped cams can be advanced or retarded relative to their gears. It begins with the ECU telling an electric solenoid to turn on, which directs a high-pressure oil stream through the cam and into a slave mechanism that ultimately changes the relationship between the cam and its gear. Valve lift and duration don't change here, like with VTEC, but none of that takes away from VCT's effectiveness, especially by 1987's standards. Depending on the engine, look for VCT on the intake side only or on both cams. At lower engine speeds, the system remains closed, leaving intake valve timing retarded for smooth idling and drivability. At higher engine speeds, valve timing advances to help retain an appropriate volumetric efficiency, which, in other words, means torque can be preserved or increased. As load increases, the system once again switches off, which allows the valves to open later and take advantage of the higher rate of air that's moving in. Unlike VTEC, Nissan's system focuses on low- and medium-speed characteristics—not so much on top-end power.

VVL

Nissan's VVL, which stands for Variable Valve Lift, does what VCT didn't. Here, valve lift and duration change by means of alternating cam lobes and a hydraulic oil pressure stream that sets everything in motion. If you didn't know any better, you'd almost mistake it for VTEC. First introduced on Japanese-only versions of Nissan's SR engines, VVL, unlike Honda's VTEC layout, has the ability to activate its high-lift intake and exhaust cam profiles independent of one another. The results are a slightly smoother transition point compared to Honda's system, which is probably why you don't hear a whole lot of talk about VVL popping or kicking in, yo.

|

| VVEL

In more recent years, Nissan's come about as close as anyone to striking the perfect balance between reduced emissions, low-speed torque, and respectable peak horsepower with VVEL. Its Variable Valve Event and Lift, shortened to VVEL, isn't as widely implemented as VVT or VVL but does something very similar. Introduced for the 2008 model year, VVEL is also a whole lot more complicated than the company's preceding systems. It first appeared under the hoods of the 350Z and G37, which feature the then-new VQ37HR engine. But more important than which cars have been slated for VVEL treatment—since all sorts of Nissans and Infinitis have since ended up with it—is exactly how it works, and just as important, why you should care about it.

|

| Nissan's latest valve timing control system is good for more horsepower, but it also accomplishes all sorts of other important things like improved throttle response, better fuel economy, and emissions that even the state of California can be happy about—arguably things just about everyone cares about. Besides managing valve events, VVEL also renders the more conventional throttle plates useless. Almost. That's because VVEL-equipped intake valves instead determine how much and for how long air is introduced into the cylinders at low- and mid-range engine speeds. BMW comes to mind here, and yes, the Germans developed this first and called it Valvetronic, but VVEL is different and, if you ask Nissan, it's better. They want you to know why.

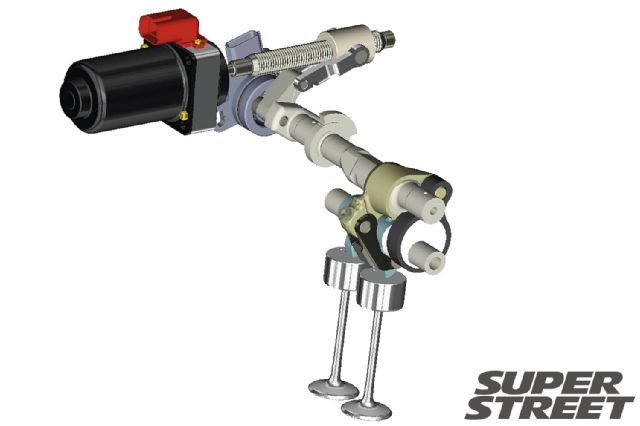

VVEL controls the incoming charge at the intake valves, and Nissan's existing CVTCS (Continuously Variable Valve Timing Control System) manages each of the valves' up and down characteristics, specifically lift and duration. Like other manufacturers' variable valve timing systems, VVEL keeps the intake valves open for a shorter period of time during moderate driving conditions. This reduces the chance of the air/fuel mixture blowing back the wrong way, which results in a more complete burn and, ultimately, more torque. At higher engine speeds the system allows the valves to open farther and for longer periods of time where the likelihood of blowback is reduced because of increased air velocity; this results in more top-end horsepower, or, the stuff that makes us care about VVEL in the first place. Here, an unconventional-looking rocker arm paired with two special links is responsible for moving the intake valves. The rocker arm imparts its motion onto an eccentric cam mounted on a small, rotating driveshaft to make all of this happen. Output cam movement is varied through a rotating control shaft inside a small, electric motor; this effectively alters the rocker arm links' fulcrums for constant valve lift adjustment. If it sounds complicated, that's because it is. Compared to what the people at BMW came up with, Nissan claims a 32-percent quicker response because of VVEL, 52-percent less parts per cylinder, and a 20-percent smaller design overall. No offense to BMW's pioneering efforts and proven technology, but anytime the same job can be done using fewer and smaller components, somebody ought to be congratulated.

|

| And then there's the green stuff. VVEL isn't just good for horsepower; it also creates a cleaner burn. For example, the VQ37HR is said to burn 10 percent less fuel and, in turn, emit fewer carbon dioxide emissions. During low- and mid- engine speeds, the intake valves handle throttle control duties, not the throttle plates inside the two throttle bodies. By controlling the intake charge closer to the combustion chamber, air travel is eased, which contributes to lower emissions. As mentioned, intake valve lift remains low at these speeds; this reduces valvetrain friction—mainly at the cams—which further lowers emissions. Nissan considered intake valve timing during start-up conditions also, when the catalytic converter's still cold and not working as effectively. Intake timing is optimized here to build exhaust heat quicker, essentially making the catalytic converter work sooner. Additionally, hydrocarbons are kept at bay through less intake valve lift at lower engine speeds. The lower valve lift helps promote additional airspeed, which creates a fine mist of fuel for more complete combustion. It makes sense, every bit of it, and is just one more reason that VTEC should never be the first or last word in the variable valve timing history books.

|

|