| Thermal Energy Recovery System - Turbo Revolution

| Thermal Energy Recovery System - Turbo Revolution

Subscribers and regular readers may recall my November 2011 column titled “Turbo Renaissance,” which touched on the resurgence of turbocharging as a way for automakers to downsize engine displacement and improve fuel efficiency without sacrificing power output. This trend has certainly gained momentum over the last few years, with everything from German luxury barges to Korean grocery getters featuring efficient and powerful turbocharged engines. And now, thanks to changes to F1’s engine regulations for the ’14 season, we’re about to witness a revolutionary way of turbocharging that has far-reaching implications for the long-term future of combustion engines.

Any F1 nerds reading this will probably know at least a little bit about what I’m getting on about, namely the switch for 2014 to 1.6L turbocharged V6 engines that are expected to produce about 550 to 600 hp, the so-called “power unit” being completed by two electric motors designed to recover braking and exhaust heat energy and bring total power output up to about 750 hp. This change has been implemented to not only increase fuel efficiency by 40 percent, but also to put a greener face on the sport and to prove F1’s relevance by promoting the production of cutting-edge technology with real-world applications.

Before taking a closer look at how the new breed of F1 turbochargers and related thermal energy recovery system (TERS) are going to revolutionize the way we think about forced induction and hybrid-electric technology, it’s worthwhile to reflect on the fact that energy is never lost, but rather is simply converted to another form. Given that as much as 75 percent of the energy generated by a combustion engine is lost in the form of heat, and approximately 55 percent of this loss is in the form of exhaust gases, it only makes sense to look at ways of harnessing this lost energy and transmitting it to the drive wheels. Of course, that’s exactly what a turbocharger is designed to do (increasing engine efficiency and output by compressing the air intake charge via a turbine that’s powered by exhaust gases), as are both KERS and TERS systems.

Combining all three of these is the new direction F1 has taken, and the move to a hybrid system to recover exhaust gas energy not utilized by the turbocharger is an indisputably brilliant, if not totally new, idea. Truth be told, electric turbo-compound engines have been around since WWII on certain airplane engines and even diesel truck engines, the advantages of which include being able to release the recycled energy in a controlled way, meaning it can be used when it’s most needed.

| Magneti Marelli, supplier to Ferrari and a number of other F1 teams, recently showcased this hybrid turbocharger for 2014. As you can see, the TERS motor-generator sits between the turbine and compressor housings, converting waste energy into electricity to be sent either directly to rear wheels via the KERS motor-generator or to the batteries for storage.

| Magneti Marelli, supplier to Ferrari and a number of other F1 teams, recently showcased this hybrid turbocharger for 2014. As you can see, the TERS motor-generator sits between the turbine and compressor housings, converting waste energy into electricity to be sent either directly to rear wheels via the KERS motor-generator or to the batteries for storage.

What’s truly unprecedented about F1’s approach to the compound engine is the use of multiple hybrid systems, meaning a direct link between the turbocharger itself and the TERS electric motor-generator as well as a link to the KERS system via the shared battery pack and motor-generator control unit (MGU). Early images of a few of the new F1 hybrid turbochargers reveal that the TERS motor-generator is mounted in line with the turbo’s shaft, between the turbine and compressor such that it can recover thermal energy that’s normally dumped out a wastegate. The recovered energy can then either be stored for later release in the battery pack or routed directly to the rear wheels via the KERS motor-generator. The net effect of linking the turbo, TERS, and KERS systems in this way is the recovery of enough heat energy to send electrified power to the drive wheels for rules-limited 33 seconds per lap, not to mention boosting engine output by a little more than 160 hp.

Actually, there is one other intriguing application for the stored TERS energy, where it’s sent back to the turbo to maintain turbine speed. This reduces inertia during the transient phase, which not only reduces turbo lag but also minimizes compressor surge. So by using the TERS motor-generator to maintain turbine speed, F1’s engine-building geniuses have found a way to both enhance turbo efficiency and reliability at the same time. That’s some high-tech win-win going on right there, not to mention both are a necessity under the 2014 F1 regulations since the cars must carry less fuel (140 liters, down from 230 liters) and their engines must last twice as long.

Some early engine design images also suggest creative packaging will be used by some of the teams/manufacturers, with the compressor sitting ahead of the engine and a long shaft linking it to the turbine through the upper part of the “V” section of the V6. This has advantages and disadvantages, the upside being a cooler location for the compressor and more compact and space-efficient intake and intercooler pipework, while the downside is a longer, heavier turbine shaft that’ll contribute to torsional and inertia issues as the turbo spools up.

The exciting part from a consumer and enthusiast standpoint is the potential application of TERS (and KERS) systems on high-performance road cars in order to boost power output as well as improve fuel efficiency. And with the TERS system being able to optimize turbocharger turbine speed, the potential is there to run higher boost levels without increasing turbo lag or wear and tear on the shaft bearings. There doesn’t appear to be any downside to TERS, other than adding a bit of weight and complexity to the overall engine and drivetrain package. And it really shows the world how hybrid technologies can be just as relevant to go-fast geeks like you and me as well as our tree-hugging friends in their slow-moving Priuses.

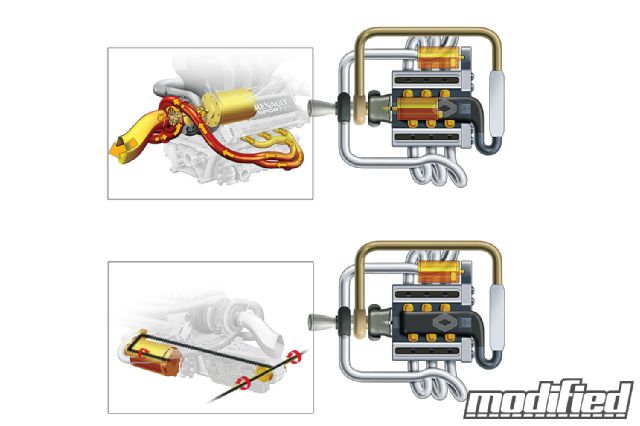

| This illustration shows how Renault may position the turbocharger and how it’s linked to the TERS motor-generator (top) and further linked to the KERS system and drive wheels (bottom). Source: ausmotive.com

| This illustration shows how Renault may position the turbocharger and how it’s linked to the TERS motor-generator (top) and further linked to the KERS system and drive wheels (bottom). Source: ausmotive.com

The more complete integration of TERS and KERS technologies on road cars will also extend the life of the combustion engine, since the energy generated by fossil fuels will be more fully utilized. That means we’ll all get to enjoy the sound of a proper suck-squish-bang combustion cycle for a lot longer than Tesla Motors would like, plus the performance aftermarket will get to embrace a new type of turbocharger and maybe even find ways to squeeze a little extra juice out of the hybrid-electric system.

We’re only just starting to get a whiff of what’s to come from F1’s new hybrid turbo V6 engines, and as a longtime Honda fanboy, I have to admit I’m pretty stoked to see the big, red H back on the nose of a McLaren as its engine supplier starting in 2015, a partnership that won four F1 championships from 1988 to 1992, not to mention giving us the legendary Senna/Prost rivalry. With the torque these new hybrid-turbo V6 engines will produce, I’m also optimistic that managing rear tire slip will help separate the top drivers from the rest of the pack, not to mention pushing Pirelli to develop a tire with more horizontal movement and slip angle capabilities. It really is an exciting time in the world of F1, and the potential for technology trickledown is greater than ever, thanks to the innovative ways the teams are implementing hybrid-electric technologies.