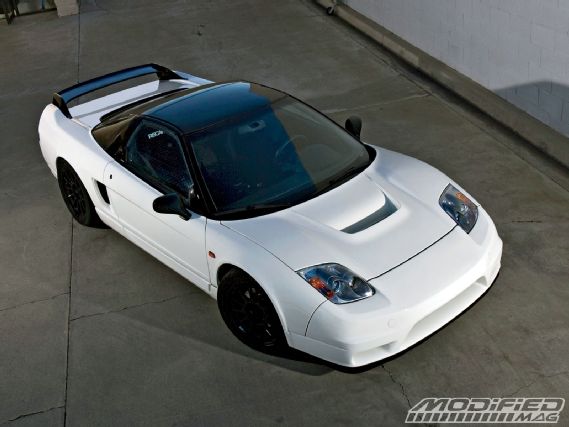

NSX owners all have one thing in common: they’re either closet or outright elitists. That’s why the fastest way to get NSX groupies in an uproar is to tell them the holy C30A or C32B engine that resides inside the NSX is nothing more than an overgrown version of the B-Series found in a lowly Integra or Civic. They’ll conveniently ignore the fact that single-cam versions of the C-Series engine all ended up in Acura Legend Sedans. But NSX elitists will have none of this and will forum-jump you with the help of thousands of their elitist friends until you are posted into submission.

|

project nsx

|

project nsx

Once you get over the usual NSX owner’s mentality, tuning the C-Series engine revolves around much of the same concepts and technologies as tuning a B-Series engine, it’s just a lot more expensive. This boils down to four basic categories in the order of how much power you’ll make and how far you want to go into debt: NA bolt ons, bolt-on supercharging, all-motor power and displacement, and turbos on rebuilt bottom ends. Only two of these solutions will not blow up the very expensive NSX transmission in the long run. Guess which one we went with.

Even though we’re perusing a pretty mundane power solution using mostly bolt-on parts, it doesn’t mean it’s all yawns. In fact, being smart about the type of bolt-ons and how they’re used to get a slight winning edge is exactly what spec racers spend a great deal of time on. Being realistic with what you want to achieve also helps. Like most Honda engines, the C30A was designed to be a high-rpm and high-horsepower engine most at home on the track. Unfortunately, 90 percent of NSXs will never see the track or be driven with the talent that it was intended for. So instead of tuning our car for big top-end power numbers that we will never see on the street, we’re going to fatten up the torque available at lower rpm and maybe see some mild horsepower gains past 6000 rpm, where VTEC kicks in. Remember, the goal of tuning a car is to make it faster, and not necessarily more powerful.

|

The Fujitsubo Ti exhaust weighs in at only 19.8 lbs for such a large muffler. Using such a larger muffler helps keep this NSX very discrete in sound as we putt around, but it still sounds beautiful when fully opened up. Upstream we also replaced the two heavy stock catalytic converters with lightweight, high-flow Random Technology units that further reduce weight as well as increase exhaust flow since the A/F ratio has now leaned out with just the cats.

|

The Fujitsubo Ti exhaust weighs in at only 19.8 lbs for such a large muffler. Using such a larger muffler helps keep this NSX very discrete in sound as we putt around, but it still sounds beautiful when fully opened up. Upstream we also replaced the two heavy stock catalytic converters with lightweight, high-flow Random Technology units that further reduce weight as well as increase exhaust flow since the A/F ratio has now leaned out with just the cats.

On the intake side, we started with a simple K&N Engineering 57 Series Fuel Injection Performance Kit (FIPK). The kit is designed to eliminate the stock airbox and panel filter assembly and replace it with an open element air filter to diminish high-rpm flow restrictions that come from the airbox. It’s basically a large cone filter fitted onto a venturi-shaped adaptor that hose-clamps onto your stock intake tubing. It might seem like a very simple solution, but according to K&N, it’s proven to make power.

We made our own little improvements by welding the intake kit onto a section of 3-inch mandrel-bent aluminum tubing, which replaces the stock baffled intake flex tube. The idea here is to eliminate the corrugated baffles or sudden changes in pipe diameter that can cause turbulence inside the tubing, which restricts flow. To ensure that the intake gets fresh cold air from outside of the engine bay, we left the stock intake air plumbing and lower intake box in place.

|

project nsx

|

project nsx

Since our NSX already came with a DC Sports header installed, much of the power gains were already made. As was, the car made 249 whp on the dyno, and because one of the simplest power gains is through a tubular header, we didn’t expect to see huge subsequent gains. Instead, we’d try to gain speed through lighter parts.

Our big weight reduction came from a new Fujitsubo Ti exhaust system. As one of the most respected exhaust manufacturers in Japan, Fujitsubo street products are made specifically to fit demure Japanese tastes. If you’re looking for a loud, annoying car, this isn’t the exhaust for you. Instead, Fujitsubo expects NSX owners to be more mature and discerning drivers, and so being, made an exhaust that is near stock in sound below VTEC, and very discrete. This is just as Honda intended and perfect for our tastes. You only get the angry howl when the car is intentionally driven in anger. Under these conditions, this exhaust tips the scales at 98 decibels, too loud to be legal for American streets. For this reason, the Fujitsubo Ti exhaust for the NSX is a special-order item here in the states. At a mere 19.8 lbs, the big benefit from the über-expensive and beautiful piece is the huge weight savings of 24.2 lbs off the stock 44-lb exhaust. Add in that we’ve taken all this weight off the end of the car means that there’s a significant change in polar moment making the car harder to spin. We also shed another 7 lbs by replacing the beefy stock catalytic converters with tubular high-flow units from Random Technology. With these two components alone we’ve moved the car’s weight distribution forward by 2 percent from 40.9/59.1 to 42.9/57.1 percent (front/rear). Added up, we’ve shed some weight off of critical sections of the car as well as gained 6 peak horsepower from our baseline.

|

To keep the exhaust subtle, Fujitsubo decided to not stamp the exhaust tips wiht the "Ti" logo unlike all their other exhausts in the Ti lineup. The hanger tubing is all hollow to reduce weight as well as the machined flanges that are only thick around the bolt holes. The purpling of some tubing sections comes from the added heat of the 180-degree turn.

|

To keep the exhaust subtle, Fujitsubo decided to not stamp the exhaust tips wiht the "Ti" logo unlike all their other exhausts in the Ti lineup. The hanger tubing is all hollow to reduce weight as well as the machined flanges that are only thick around the bolt holes. The purpling of some tubing sections comes from the added heat of the 180-degree turn.

The last trick in our bag is to modify the original DC Sports headers. There’s nothing wrong with the out-of-the-box headers, but if you’re all uptight on squeezing out every bit of power from bolt-on plumbing, this is something that’s worth looking into. Most mass-production aftermarket tubular headers are exactly that—mass produced. Even a well engineered product like the DC unit has to save a little money in manufacturing to make it affordable. To do this, the collector (where the three primary tubes leading from each cylinder head merge together into one pipe) is typically a large pipe pinched around the three primary pipes and the entire thing is sealed together with a lot of weld. It’s ugly, but gets the job 80 percent done.

|

Burns Stainless specializes in custom-built merge collectors that provide a smooth transition for each exhaust primary to collect into. The use of a merge collector is something typically done only in professional motorsports and is worth a noticeable gain in power and torque.

|

Burns Stainless specializes in custom-built merge collectors that provide a smooth transition for each exhaust primary to collect into. The use of a merge collector is something typically done only in professional motorsports and is worth a noticeable gain in power and torque.

But there’s a secret to optimizing a header to your engine, and it’s not just in the proper length of the header primaries. The secret is a higher-quality merge collector that provides a very smooth transition for exhaust gas pulses to merge as they travel down the primaries. Few people know about this topic matter better than Jack Burns and his team at Burns Stainless in Costa Mesa, California. They specialize in making stainless and inconel exhaust parts for pro-level race cars and are world-renowned for their products among pro-stock drag racers, NASCAR and land-speed nuts.

The idea behind a proper merge collector is to not only smoothly merge the exhaust pulses from each cylinder, but also to take advantage of these exhaust pulses to help the engine breathe better through exhaust scavenging. Long story short, the merge collector can increase the amount of fresh air sucked into the combustion chamber by reflecting a negative pressure exhaust pulse back from the collector to the exhaust port. The negative pressure wave is essentially a vacuum that helps suck fresh air into the combustion chamber during valve overlap. There are two critical parts to building a header so that the reflected wave hits the exhaust valve right when both intake and exhaust valves are slightly open: the length of each primary and the dimensions of the collector. Since every engine is different, primary length and the merge collector dimensions have to be designed based on the engine (and user’s) target rpm, valve dimensions and cam specs. Burns Stainless does this using their 30 years of experience and their proprietary X-Design software that models an engine based on the exact specs that you send them. So if you just bought some random merge collector to put onto your car, chances are it won’t work as well.

|

Burns Stainless took our DC Sports headers and cut off the original collectors to be replaced with their merge collectors. The small expansion cone after the merge is also critical in increasing exhaust scavenging. Each collector is custom-built and designed for a specific engine's parameters to optimize flow.

|

Burns Stainless took our DC Sports headers and cut off the original collectors to be replaced with their merge collectors. The small expansion cone after the merge is also critical in increasing exhaust scavenging. Each collector is custom-built and designed for a specific engine's parameters to optimize flow.

In our case, the DC headers already come with fairly equal-length primaries, ranging between 30–33 inches each. According to the team at Burns, this is pretty much on the dot for a Honda engine that’s running on the big VTEC cam lobe. This means that we didn’t have to adjust the primary lengths and could just cut off the original DC collector and replace it with a Burns custom fabricated merge collector. In addition to the smooth merge, the Burns collector has one additional trait. It pinches the merge diameter down first before expanding the pipe diameter again. It’s counter-intuitive, but this pinch and its precise dimensions are actually what helps reflect the exhaust wave to increase scavenging.

At Burns’ suggestion, we did just a bit of fine fuel tuning with an old A’PEXi S-AFC to make sure the new headers were optimized. We only ended up taking out a few percent of fuel above 7000 rpm.

|

Project Acura NSX Fujitsubo Exhaust - More With Less

|

Project Acura NSX Fujitsubo Exhaust - More With Less

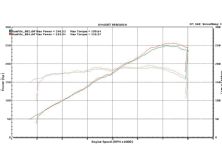

With just the intake, exhaust, original headers and high-flow cats, we took the NSX from its 249-whp baseline (already with headers) to 255 hp. We retested the car with the new collectors and tuning and saw only a 1hp peak gain. We expected this since we asked them to optimize the collector for more midrange torque which is what we got. In the case of a high-revving NA motor, midrange torque will actually help the car get out of corners faster than just a few more horses at redline. From 3000 rpm up, the torque gain is maintained all the way through redline. At its best, we almost picked up 10 ft-lbs of torque.