In last month's issue, we focused on the intercooler placement and mounting, as well as introducing the Turbosmart wastegate and blow-off valve combo that would make their way into the build. Although Whitfield Racing has been extremely busy, they were able to make some more progress on the fabrication side.

First and foremost, the intercooler placement was finalized, the custom-built end tanks were welded in place, and a support bridge that bolts securely to the core support using factory holes was completed. The charge piping was also finished with a V-band connection to the passenger side of the intercooler and the Turbosmart Race Port blow-off valve was welded in place. Just to the side of the charge piping, the custom breather box/overflow tank that was covered previously received a set of high-quality Goodridge -10 lines that snake to the rear of the valve cover where they connect using a pair of black Goodridge 90-degree fittings.

| 1992 Acura Integra GS-R - Project DB2 Pt. IV

| 1992 Acura Integra GS-R - Project DB2 Pt. IV

| 1992 Acura Integra GS-R - Project DB2 Pt. IV

| 1992 Acura Integra GS-R - Project DB2 Pt. IV

| Jason Whitfield and Kevin Valdez are installing the newly finished Vibrant Performance intercooler with Whitfield’s custom end tanks and mounting tabs.

| Jason Whitfield and Kevin Valdez are installing the newly finished Vibrant Performance intercooler with Whitfield’s custom end tanks and mounting tabs.

| 1992 Acura Integra GS-R - Project DB2 Pt. IV

| 1992 Acura Integra GS-R - Project DB2 Pt. IV

|

|  | 1992 Acura Integra GS R Goodridge Black Braided 10 Lines 05

| 1992 Acura Integra GS R Goodridge Black Braided 10 Lines 05

|

| Comp Turbo, of Pomona, California, provided one of the most vital pieces of the puzzle: the turbo we'll be using on Project DB2. Established in 2007, Comp Turbo manufactures some of the most advanced turbochargers in the industry, from micro-sized units intended for two-stroke engines, all the way up to fire-breathing, 3,000-plus horsepower dragsters—they do it all. For this street car, I didn't want a massive turbo that would bring big peak numbers on the dyno, yet lack the midrange to enjoy the car on the street. A balance of driveability and power is key, and though I don't have a specific number in my head, I'd like the car to see somewhere around 400 hp safely, once all is said and done. The unit we're using is a Comp Turbo CT4 billet T3 6062 AR .63, or CT4 housing, T3 frame, 60mm inducer, with a 62mm exhaust, utilizing Comp Turbo's 360 journal bearing technology. Kevin Valdez of Whifield says, "We decided to go with a small billet wheel turbo so we wouldn't sacrifice too much power in the midrange, but we also wanted to be able to reach up to 500 whp at the flip of a switch. The Comp Turbo billet 60mm was the perfect turbo for this build, and it's fully upgradable at anytime." Using Comp Turbo's CT4 housing gives us the ability to move up to a 67mm in the future if the itch for more power is too much to deny.

| 1992 Acura Integra GS-R - Project DB2 Pt. IV

| 1992 Acura Integra GS-R - Project DB2 Pt. IV

Comp Turbo delivered a gorgeous CT4 billet T3 6062 AR .63 unit, which is connected to a custom Whitfield airbox with a Vibrant Performance Vanjen clamp.

Whitfield held off on completing the custom airbox until the turbo arrived in order to avoid any fitment issues. With the Comp Turbo snail in place, final measurements for a perfect fit were taken and the one-off intake was finalized with Vibrant Performance's Vanjen clamp system. A duct in the front bumper with piping leading to the bottom of the box will be sorted once time permits.

The V-band mounts for Turbosmart's Hyper-Gate 45 are now welded properly, and rather than sending gases into the atmosphere directly, they'll instead be routed into the exhaust path. Expecting plenty of movement under load, a Vibrant Performance 1? stainless bellow was added to the wastegate's exhaust path and uses a slip fit that's secure, but grants some "wiggle room" as well. Jason Whitfield adds, "It's great for the flex, especially in a street car and the additional stress of going back into the exhaust system. Also, the Vibrant piece is way smaller than a traditional flex pipe ... and looks way cooler."

| 1992 Acura Integra GS-R - Project DB2 Pt. IV

| 1992 Acura Integra GS-R - Project DB2 Pt. IV

| 1992 Acura Integra GS-R - Project DB2 Pt. IV

| 1992 Acura Integra GS-R - Project DB2 Pt. IV

|

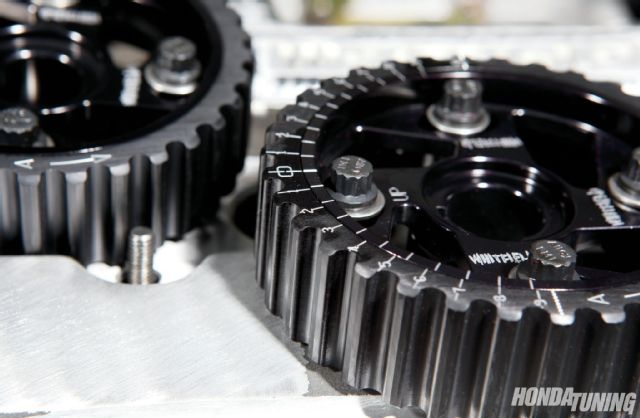

| Next up on the agenda is figuring out a custom-sized radiator that will grant the most efficient cooling, trimming the valve cover to grant easy access to the Whitfield Racing signature cam gears that will be used, and sorting out the duct for the front bumper. Plenty more is still to come from Project DB2 and Whitfield Racing, stay tuned ...

|

|  | 1992 Acura Integra GS-R - Project DB2 Pt. IV

| 1992 Acura Integra GS-R - Project DB2 Pt. IV