It’s been months since we last left off with our Project S2K build (May ’11 issue), and during that time, our loyal readers have bombarded us with phone calls and emails, randomly guessing how the build would evolve, all the while pleading for more information. Well, we’re back with our third and final installment in our quest to build the ultimate street/track S2000.

|

Project Honda S2K

|

Project Honda S2K

The goal in motorsports is always to go faster, as untold dollar amounts are spent on improving the performance of race cars with better suspensions, more power, grippier tires, or more complex electronics. Being fast is a key factor in improved lap times, but selecting the right components is just as important. As the saying goes: “Do it right the first time or don’t do it at all.” In summarizing our project, we upgraded the S2000 with an array of quality products, including a C-West aero kit, Spec clutch, Kaaz 1.5-way limited-slip differential, DC Sports header and exhaust, Wilwood big-brake kit, Tein Mono Flex coilovers, Suspension Techniques sway bars, Volk Racing Generation 2 18x9 +40mm offset wheels and 255/40-17 Falken RT-615K tires, along with various DME suspension components.

As our build slowly comes to an end, we close this saga by completing our i-VTEC install before heading to the dyno for some tuning in preparation for one ultimate goal: time-attacking Buttonwillow Raceway’s infamous clockwise-13 (CW-13) configuration to a sub 2-minute lap time.

Defi-Link Meter Advance ZD

Optimizing the performance of every vehicle starts with understanding what the engine is doing and how it is performing, and gauges help make this possible. Instead of overwhelming our interior with gauges, we decided to keep things clean and simple and install an all-in-one Defi-Link Meter Advance ZD. The Defi unit enables us to monitor up to six parameters at any time, including vehicle speed, voltage, clock, oil temperature and pressure, water temperature, fuel pressure, and exhaust gas temperature (EGT). The unit also features a programmable, superbright, quick-reacting LED shift indicator that lights up and flashes based on engine rpm.

|

Project Honda S2K

|

Project Honda S2K

Odyssey Battery

We removed additional weight from our S2000 by replacing our OEM battery (44 pounds) with an Odyssey PC925 battery (24 pounds).

|

Project Honda S2K

|

Project Honda S2K

EVS Custom Splitter

Evasive Motorsports located in La Puente, CA, built us a splitter based upon their track-tested and proven design for the S2000. Evasive used our C-West bumper to mock up a template before gathering the necessary materials to begin construction. Three days later, Evasive completed what they consider their “basic” splitter using carbon fiber that also incorporated front-tire block-off plates integrated into the splitter design to cover the front tires, reducing parasitic drag and lift.

|

Project Honda S2K

|

Project Honda S2K

Spoon Sports Rollbar

A Spoon Sports four-point rollbar was installed to protect our driver and allow usage of five-point harnesses with our Buddy Club bucket seats. The rollbar is the perfect setup for our S2K for either street/track driving, as it can be used with both soft top and hardtop.

|

Project Honda S2K

|

Project Honda S2K

Voltex Wings

For the track, we decided to use a Voltex GT Type 3 wing with its aggressive double-step design. The Voltex Type 3 wing was recommended by Evasive Motorsports to deliver maximum downforce in conjunction with our C-West aero and custom EVS front splitter.

|

Project Honda S2K

|

Project Honda S2K

For street driving duties, we replaced our Type 3 wing with the less attention-grabbing Voltex Type 1V as shown in our photo. The Type 1V is designed specifically for the Honda S2000 and is recommended for daily driven cars with minimal aero mods.

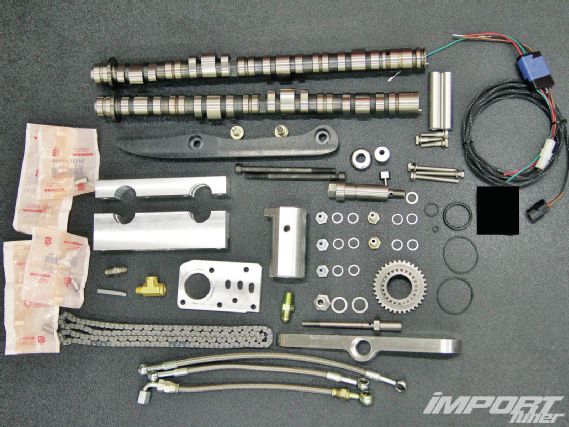

Design Craft ECS (Electronic Control Sprocket) I-VTEC

Known as “intelligent VTEC”, i-VTEC allows for dynamic/continuous intake valve timing and overlap control, enabling adjustments to the cam timing to allow optimal power. Gary Castillo, owner of Design Craft Fabrication and mastermind behind the ECS i-VTEC system, claims gains of 20 to 30 hp and 25 to 35 lb-ft of torque on average with naturally aspirated setups. “It’s a proven fact that electronic cam timing can make plenty of low to midrange power,” Castillo says. “The greatest thing about the ECS system is that you don’t have to pull your engine to install the kit, and it’s completely removable within a full day.” In continuing our ECS install, we swap in a new set of camshafts, dial in our cam timing and wire up the VTC oil pressure solenoid valve before attempting to fire up the car.

|

Project Honda S2K

|

Project Honda S2K

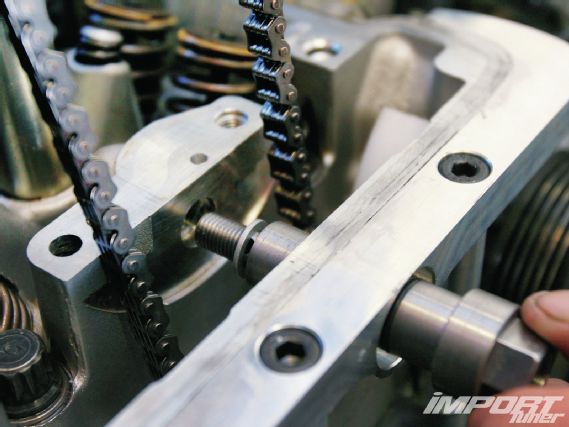

Design Craft replaced our F22C’s 23-tooth, factory crank sprocket with their custom 22-tooth unit included in every ECS i-VTEC kit. The smaller-sized crank sprocket causes a gap between the chain and the factory oil pump chain guide, which—left unaddressed—can cause excessive slack in the chain that leads to skipping of teeth.

To address the chain gap, Design Craft provides an offset pin, which allows you to adjust the oil pump chain guide closer to the crank sprocket. The side-by-side image shows both before and after modification using the offset pin.

Instead of teeing off the factory oil pressure sensor, Design Craft modified the factory timing chain cover to retrieve a more consistent oil supply.

|

Project Honda S2K

|

Project Honda S2K

Provided with every kit is an ECS i-VTEC sandwich plate, which allows proper valve cover clearance.

|

Project Honda S2K

|

Project Honda S2K

Utilizing many of the factory features, Design Craft designed the oil feed advance bolt to use the original idler sprocket bolthole. The oil feed advance lets the cam sprocket allow cam phasing.

|

Project Honda S2K

|

Project Honda S2K

The ECS kit includes an i-VTEC specific camshaft grind for naturally aspirated or forced-induction engines. Both camshafts are machined out of billet steel for better wear quality and don’t require aftermarket valvesprings.

|

Project Honda S2K

|

Project Honda S2K

| Project Honda S2K

| Project Honda S2K

| Project Honda S2K

| Project Honda S2K

The photo shows stamping on the trigger wheel marked “outside” for the factory S2000 cams. With the new i-VTEC setup, the trigger wheel needs to be installed backward now that the cams spin in a clockwise rotation.

The supplied oil retard bolt uses an aluminum crush washer on the upper cam journal and a rubber O-ring on the lower cam journal to ensure a proper seal and eliminate oil pressure drop.

|

Project Honda S2K

|

Project Honda S2K

The ECS i-VTEC valve cover can be purchased outright or credited as a core charge. Design Craft can even powdercoat your new valve cover in wrinkle red or black for an additional charge

|

Project Honda S2K

|

Project Honda S2K

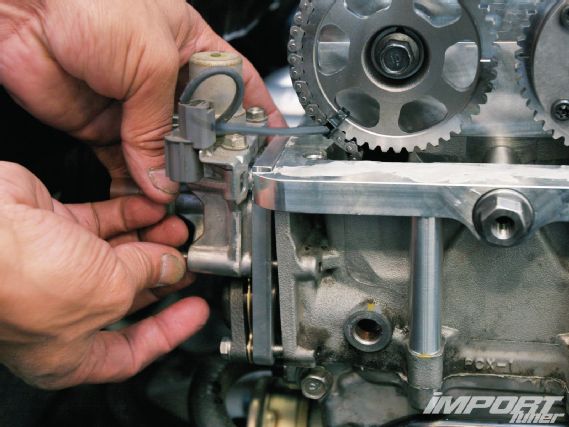

The remote VTC oil pressure solenoid valve is the most essential part of the ECS i-VTEC conversion. The unit basically works like the factory K-series i-VTEC module but remotely.

|

Project Honda S2K

|

Project Honda S2K

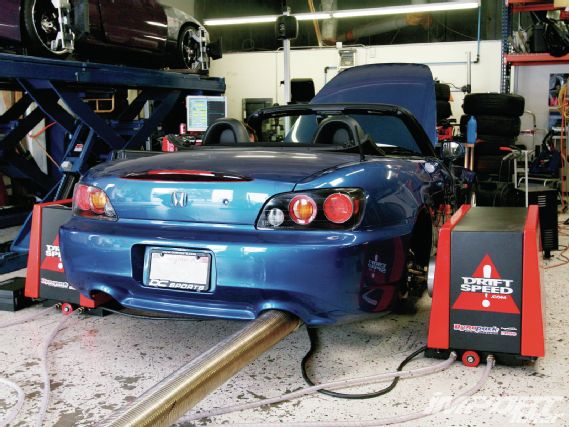

Tuning For Horsepower

Upon installing our i-VTEC setup, we enlisted the aid of Mitch Pederson of MP Tuning to tune our S2000. Pederson, a former AEM engineer who was part of a team responsible for developing the EMS fuel management system, made the necessary modifications to our AEM unit to work with the newly installed i-VTEC by modifying jumper settings within the ECU and pins around at the ECU connector. MP Tuning also supplied a drive-by-wire jumper harness to make the system a plug-and-play affair, and also included an engine wiring harness to connect the intake cam oil control solenoid to the ECU.

|

Project Honda S2K

|

Project Honda S2K

Before firing up the engine, Pederson made changes to the calibration settings within the EMS to recognize the intake cam position and set up the closed-loop cam angle control. An AEM wideband UEGO gauge was installed prior to tuning, to aid in monitoring the vehicle’s air/fuel readings. Drift Speed, located in Los Alamitos, and EDO Performance of Huntington Beach, graciously offered their dyno facility for tuning the vehicle on numerous occasions.

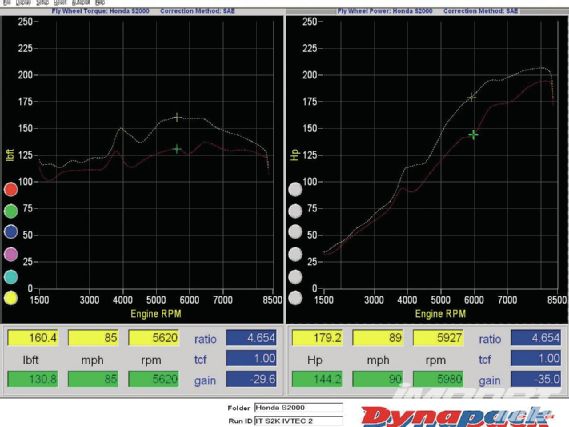

A comparison between dyno pulls with the cam timing turned off (i.e. full intake cam retard versus with the cam timing optimized at all engine speeds) revealed a noticeable increase in the midrange power and torque due to the variable intake cam timing—the new i-VTEC setup posted a whopping increase of 36 hp and 37 lb-ft of torque at 4,000 over our standard VTEC numbers. Considering most intake, exhaust, and header bolt-ons only deliver an average of 5 to 10 hp, it’s easy to appreciate the power gains of the ECS i-VTEC system.

|

Project Honda S2K

|

Project Honda S2K

S2K Driver Search

Over the years, 2NR has grown a close relationship with Eiji “Tarzan” Yamada, who’s helped on several occasions with our own track testing. We called him once again for a favor: Drive our S2000 at Super Lap Battle. Tarzan’s no stranger to the podium. He’s most famous in the time-attack community for shattering the Tsukuba Revspeed Super Battle record with a 54.925 lap in 2009, and becoming SLB champion in 2004 with a 1:48.90 lap around the Buttonwillow CW-13, both accomplished in the infamous Cyber EVO from Unlimited Garage/Sun Auto. After a few back-and-forth conversations via email, Tarzan agreed to take the helm of our Project S2K. It was an amazing feeling to have someone of Tarzan’s caliber in our corner, but with all the changes that had taken place with the car from stock, we weren’t sure how the car would handle its first time on the track. Regardless, we had one week before our deadline. We thrashed to assemble the car before dropping it off at Evasive Motorsports for a full race alignment and corner balance, with a 170-pound driver ballast to obtain proper weight distribution.

|

Project Honda S2K

|

Project Honda S2K

Redemption day: Buttonwillow Raceway

While preparing for the morning’s first session, we scrambled to mount the necessary fifth-point harness and some finishing touches, causing Tarzan to miss his first practice session. After the guys from Tein aided in tweaking the suspension, Tarzan was able to make his first pass. Watching from the paddock, we noticed the S2000 exhibit understeer as he manhandled it around the track.

|

Project Honda S2K

|

Project Honda S2K

After a quick 5-minute session, Tarzan returned to the pits and offered some input on the car’s handling. After some adjustments to the sway bar settings, lowering tire pressure, and adjusting spring preload to the front and rear coilovers, the car was sent back out for its first official lap time of the day. Tarzan managed to get three laps in, with a best time of 2:01.93. We were so close to accomplishing our goal we could taste it!

On his second session, the S2000 recorded a time of 2:01.02 on the first hot lap; just as the tires were warming up. But just as he entered his second, Tarzan called in that the car was down on power. Back at the pits, we immediately pulled the valve cover and began troubleshooting the problem, eventually finding that the hall-effect sensor that was replaced for the i-VTEC’s drive-by-wire system was faulty.

As happy as we were about finding the problem, the challenge of solving it wasted more than half the day. We were able to make repairs and restore the vehicle’s power just in time to make the final session. But due to track temperatures cooling off, the car was not able to get a clean pass, and we found ourselves unable to best our 2:01.02 performance.

Although we improved upon our initial 2:12.348 Buttonwillow lap time when our project first began (Apr. ’11 issue), we’ve gone back to the drawing board, planning to revisit Super Lap Battle with even more power via forced induction, and additional suspension modifications. And we have a new goal: 1:57. Call us crazy, but it’s the goal we’ll be staying busy in the upcoming months!

Driving Impressions with Eiji “Tarzan” Yamada

Super Lap Battle was a good shakedown session for the 2NR S2000. After giving the car all it was worth around the Buttonwillow circuit, the S2000 was a blast to drive. The stiffer suspension settings, stickier tires, better aero work, and hardtop made it a truly terrific track-day weapon. With the i-VTEC setup, the Honda offered excellent midrange power when exiting the corners. Although the car could have used a bit more horsepower, the handling was quick and responsive and near neutral, with just a bit of understeer that was easily corrected with a tap of the throttle to point it in the right direction. With added horsepower, I think this car can be considered on par with the Amuse S2000 in terms of handling capability. [We nearly jumped out of our skin when Yamada offered comparisons to Amuse. -Ed.] I hope to return to Super Lap Battle with anticipation of climbing back into the driver seat to improve our lap times.

|

Project Honda S2K

|

Project Honda S2K