The S2000 has earned a reputation for having a fragile rear end. A quick search on s2ki.com reveals countless differential housing failures, especially in cars with high-power turbocharged setups. To ensure our S2K doesn't have a day at the track cut short by a diff failure, we sought out the legendary "PuddyMod," aka Ben Herne, to work his magic on our AP2 differential.

|

Project S2000 - A Rear With No Fear - Tech

|

Project S2000 - A Rear With No Fear - Tech

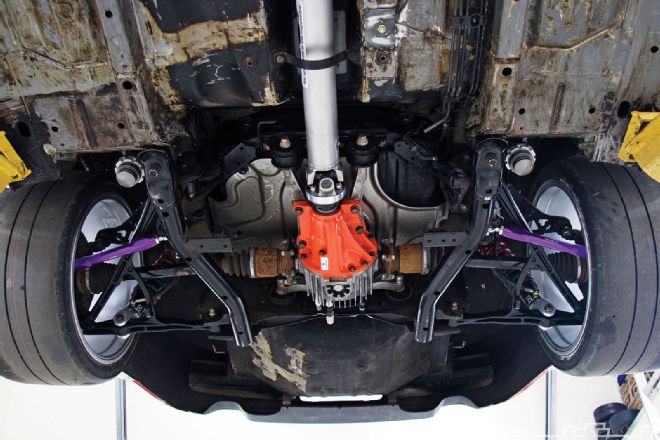

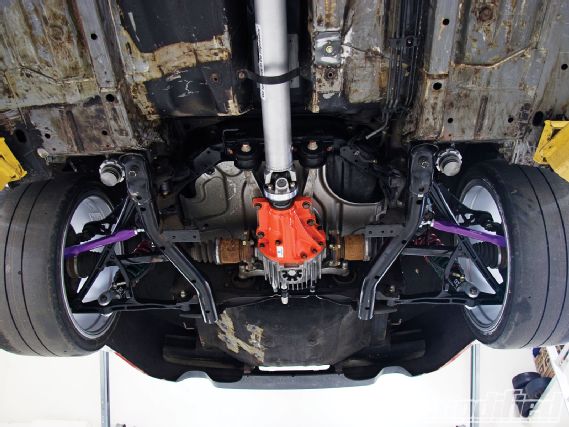

With the stock diff drained and removed from the car, we shipped it off to PuddyMod for the full Stage 4 treatment. This includes cryogenically treating the complete assembly and reinforcing the housing to withstand stresses up to 200,000 psi (stock is approximately 60,000 psi). Next, the gears are fully deburred, shot-peened and then polished for smoother, cooler and quieter operation. A black phosphate process is used to treat the custom-made components, just like on firearms. Finally, a custom 1020 DOM (Drawn Over Mandrel) steel pinion sleeve is fitted and the precision balanced components are assembled to PuddyMod's top-secret tolerances and treated to the signature orange finish on the housing.

The custom pinion sleeve is a very important part of the build process and is a solution that has been employed in racing/high-power applications for years. The stock pinion sleeve is a torque-to-yield piece that requires continued tightening to compress the sleeve during assembly until the specified bearing preloads are reached. This works fine until the diff is loaded to the point that the pinion sleeve compresses further than it's designed to, resulting in decreased bearing preload and pinion float. This will eventually cause failure of the rear end as the crown and pinion begin to slam into each other. The reason Honda (and most manufacturers) don't fit a solid pinion sleeve is due to the cost and time involved to produce them. The PuddyMod pinion sleeve is hand-turned and ground to the exact dimension needed for each differential. This eliminates the need for shims or collapsible-type sleeves, resulting in improved reliability. This recipe has resulted in great success within the S2000 community, and it's no surprise that PuddyMod stands behind every diff it builds (which also include the Nissan R200, BMW, Ford 8.8, Toyota Supra and Celica and Mazda Miata).

While the S2000 rear is fitted from the factory with a helical-type LSD, we opted to fit a 1.5-way ATS (Active Traction Service) Super Silent clutch-type version to improve stability in braking/corner entry and help put the power down to the ground on corner exit. One major drawback with the helical diff: If traction on the unloaded wheel goes to zero, so does the torque transfer across the diff, and the unloaded wheel will spin up. With a clutch-type LSD we can safely bounce curbs and not worry about destroying the LSD when the inside wheel hits the ground. ATS has also shown great success in motorsports this season, with its LSDs dominating the Civic One Make series in Japan, currently holding first, third and fourth in the championship.

|

Check out the high-strength bearing caps. These ensure the diff doesn't try to escape from the housing.

|

Check out the high-strength bearing caps. These ensure the diff doesn't try to escape from the housing.

The ATS Super Silent clutch-type LSD features advancements that help achieve excellent performance while maintaining good driveability and silent operation by developing a concentric groove pattern for the friction plates, which ensures adequate lubrication at all times, as well as preventing noise and chatter. Following heat treatment to help smooth engagement and further reduce chatter, the opposing plates are ground to achieve uniform flatness. The diff also features a wide range of adjustment to achieve ideal engagement and response. The friction plates can be arranged from 12 (super silent setting) to 16 (increased breakaway torque) to adjust the initial breakaway torque. The cam angle is also adjustable between 45 degrees (slightly laggy response) to 60 degrees (immediate response). We ordered our differential with the 16-plate configuration to ensure excellent holding capacity while opting for the 45 degree cam angle to help minimize understeer at partial throttle/mid corner. Testing will reveal if this is the ideal setting, and with the ATS differential we can make any adjustments needed.

One factor to consider with metal clutch-type LSDs is that they generate substantially more heat during track use when compared to the factory helical-type LSD. Consequently, we had PuddyMod install a pickup port to feed our Tilton differential pump and cooler assembly (stay tuned for more on this) as well as a temperature sensor port. The return from the cooler is fed to the factory fill port using a -8 to M18x1.5 AN fitting and -8 Startlite hose. Alternately, PuddyMod can install enlarged cooling fins on the rear cover to help improve cooling, but with our plans for a sealed flat bottom, the cooling fins would be ineffective.

Finally, we had PuddyMod install a Mazdaspeed 3.9 final drive with ATS hardware to match the gearing in our Quaife 60G sequential gearbox. We received our diff from PuddyMod with the break-in procedure already completed and ready for battle. How cool is that? Installation was straightforward, and our S2K's rear end is now ready for the turbocharged power that Full-Race has coming for it very soon.