| Project Mitsubishi Evolution IX - Tech

| Project Mitsubishi Evolution IX - Tech

If you've never autocrossed before, you owe it to yourself to dodge a cone at least once. It's fun, safe, will teach you how to handle a car at its limits and there's no better satisfaction than spanking cars that cost twice as much with a faster time.

And as you get more into it, it always pays to scour the SCCA Solo rulebook (found at www.scca.org) when aiming for any particular class. It's no fun being bumped up classes in a 120bhp Civic and having to take on tube-framed, huge-winged Modified class cars. For SCC readers, the Street Touring (ST) and Street Prepared (SP) classes are the perfect stomping grounds for those who are serious about modifying their cars.

| Project Mitsubishi Evolution IX - Tech

| Project Mitsubishi Evolution IX - Tech

Classified specifically into B Street Prepared (BSP) under the SP umbrella, Project Evo IX will be retaining the stock turbo and brakes, but will receive a custom coilover suspension, an increase in boost, a turboback exhaust, select urethane suspension bushings, wider wheels and, unfortunately, race tires and gas. Unfortunate because of the price. Any octane of unleaded gasoline is allowable in BSP, as well as any DOT-approved race tire of any size. This means that, if you really want to win and take it to the limit of the rules, run Hoosiers or Kumho V710s (285-width for an Evo) and a bare minimum of 100-octane.

| Project Mitsubishi Evolution IX - Tech

| Project Mitsubishi Evolution IX - Tech

Drivers who have used them know that Hoosiers and V710s are the worst kind of performance-enhancing drug. They hit hard and fast, but leaving you wanting more. The twin-grooved semi-slicks will barely last a weekend at full softness and they're not exactly a bargain to begin with.

We're going to use two wheel/tire sets on Project Evo IX, one for the street and one for the track. But because we're trying to balance autocross with open track use as well, we're going with a longer-lasting race tire (than Hoosier) that still offers loads of grip (so we don't get dusted in BSP) and will cost less in the end (the heavy Evo eats tires at the track). With wheel size and width virtually open in BSP, we're going to try Project Evo IX with 18x9.5 Hyper Gunmetallic 5Zigen ZR+520 wheels and Toyo Proxes R888 tires. We won't be packing maximum heat for the Solo national championships, but we should be fine at the regional level.

| Project Mitsubishi Evolution IX - Tech

| Project Mitsubishi Evolution IX - Tech

The Toyo R888 tires have all the obvious R-compound prerequisites: huge tread blocks, stiff sidewalls, a soft compound and wide sizes. When we asked Toyo for details, the company was confident in the tires' ability to provide grip and long life, and also do well at autocross events-which don't see much in the way of tire warm-up time before going on course. We ordered a set of conservative (for an Evo) 265/35/18s. When they arrived, we were pleasantly surprised to find that they run wide for their size. Mounted on a 9.5-inch wheel, the R888s measure 10.7 inches sidewall to sidewall, which is comparable to a 275/35/18 Toyo T1R street tire. The R888s are also surprisingly quiet during daily duty.

| Project Mitsubishi Evolution IX - Tech

| Project Mitsubishi Evolution IX - Tech

The only reason we know that precious tidbit is because of a stock wheel failure. At The Streets of Willow Springs circuit, Project Evo IX came cresting over a blind hill at near triple-digit speed into a quick braking zone. A wheel dipped too much to the right here, a rock-filled rut there and, before you knew it, the Evo bounced its right side over a bump. There appeared to be no suspension damage, but telltale steering vibration said it all: the front right stock 17x8-inch wheel was bent. The wheel repair company would later diagnose it as a shifted outer face, a problem that can't be repaired. Thus, the 5Zigen wheels and R888 tires went on (with the stock suspension) for commuting.

| Project Mitsubishi Evolution IX - Tech

| Project Mitsubishi Evolution IX - Tech

Later, displaying our utterly impressive editorial might, we contacted our friend Maurice Durand, manager of product PR at Mitsubishi, and he helped us source a replacement factory wheel. In an effort to stock up on spares, we also called evo guru Robert Fuller of Robispec, who connected us with a cheap set of stock Enkei wheels (thanks also to Chris and Kevin).

| Project Mitsubishi Evolution IX - Tech

| Project Mitsubishi Evolution IX - Tech

As the latest release from 5Zigen, the cast one-piece ZR+520 is designed for strength and an easy fit. After bending what we thought was a nearly indestructible Enkei, we're big fans of strength. The 18x9.5 wheel, with a plus-30mm offset, fits the Evolution platform perfectly. The front wheels clear the Brembo calipers with ease and the wheel/tire combo can even clear the stock suspension, although rolling of the rear fenders was absolutely necessary. Our late-night, last-minute request was handled by Teddy Hiraoka and the fender roller of Mavrik Motorsports.

| Project Mitsubishi Evolution IX - Tech

| Project Mitsubishi Evolution IX - Tech

The only real downside to the ZR+520 is weight. At 26.5 pounds each, there are many lighter options. With the 265-width R888 mounted, our race tire package weighs 4.5 pounds more per corner than our 245-width street tire package (53.5 pounds versus 49 pounds). But it's a balance, because you'd be hard pressed to find a wheel that can beat the ZR+520's ease of installation, price, size and availability.

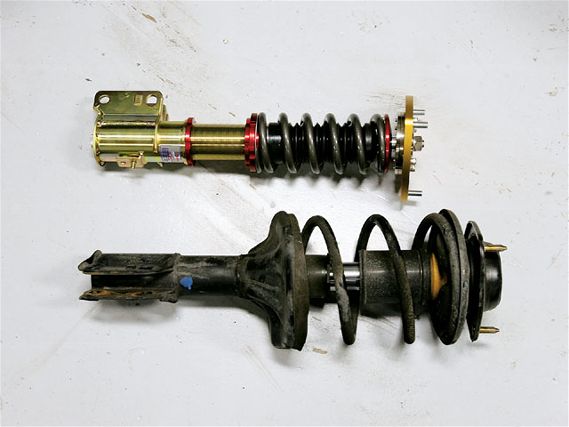

With our rolling stock figured out, it was time to tighten up the suspension. The ST and SP classes allow the same important suspension modifications, but we'll always reference the Street Prepared section of the rulebook. According to SP rules, we could use any shock absorber (Section 15.5, C), adjustable spring perches (15.8, A), different bump stops (15.8, B) and adjustable camber plates (15.8, F). A chance encounter with Jon Kaneda of JIC Magic convinced us to try the new JIC FLT-TAR coilover suspension system. But we didn't want the normal off-the-shelf system; no, we wanted the kit that was on the 2007 Super Lap Battle Street Class-winning M1 Evo VIII.

| Project Mitsubishi Evolution IX - Tech

| Project Mitsubishi Evolution IX - Tech

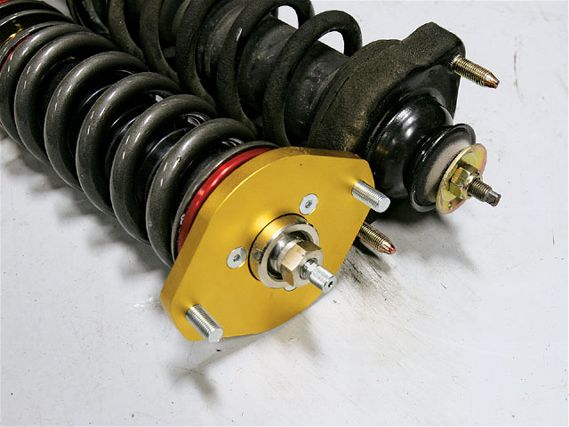

Compared to the 'normal' FLT-TAR coilovers, ours still retain the 15-position adjustable inverted front monotube and monotube rear dampers, independent (from suspension travel) ride height adjustment and upper spherical bearing front camber plates. Where our coilovers differ is the use of spherical bearings instead of rubber in the rear upper mounts and custom spring rates. We opted to go with 10kg/mm springs in the front and a stiffer 12kg/mm rate in the rear to aid with ass-end rotation. A big plus was the loss of seven pounds per front corner with the FLT-TARs (14 pounds versus 21 pounds stock) although the rears gained one pound (12 pounds versus 11 pounds stock).

| Project Mitsubishi Evolution IX - Tech

| Project Mitsubishi Evolution IX - Tech

After installation, we headed to M1 Fabrication & Development for advice on alignment settings. Autocross and road course demands generally require two different alignment setups, but we needed a ballpark to get started. According to the rulebook (15.8, J), we were free to dial in whatever alignment settings we could, using only the parts that we just installed. We aimed for three degrees front camber and two degrees rear camber, with zero inches of toe all around. We hit our camber settings easily (be sure the front stock camber bolt is oriented the right way or you'll sacrifice almost a degree of camber) and ended up with 1/32-inch of total toe out in the rear.

| Project Mitsubishi Evolution IX - Tech

| Project Mitsubishi Evolution IX - Tech

After road testing, we ended up with a street setting of seven clicks from full hard up front and five clicks from full hard in the rear. Make no mistake, this is not the most comfortable suspension in the world. There are harsher cars (the old FD3S RX-7 R1 comes to mind), but Project Evo IX is as stiff as Kaneda warned. This can largely be attributed to the heavy rear spring rates we've chosen, but the Evo needs as much help as it can get to avoid beating up the front tires at speed. If you're concerned about ride comfort, stick with the standard JIC configuration. But if you're looking to go fast, ask for the SCC formula.

| Project Mitsubishi Evolution IX - Tech

| Project Mitsubishi Evolution IX - Tech

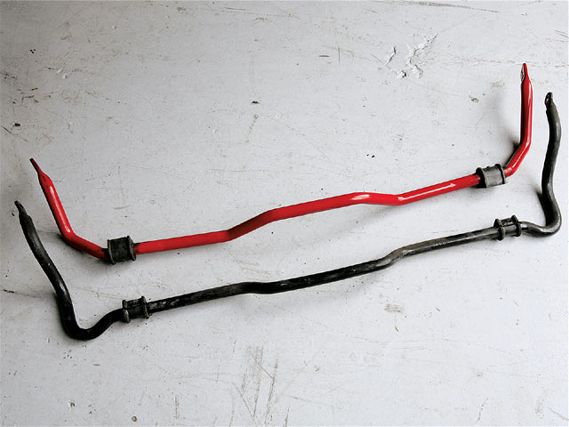

With our dedication to oversteer strong, we soon found that Project Evo IX still didn't rotate as well as we wanted, even during simple road testing. Looking for more life from the rear end, we added a 24mm adjustable Hotchkis rear anti-roll bar (allowable under section 15.7 with a bushing change). The Hotchkis bar is a cheap buy that slots into the stock location with ease. We did, however, have to drop the rear muffler and one rear lower control arm to gain enough room to wiggle the stock anti-roll bar out of place.

| Project Mitsubishi Evolution IX - Tech

| Project Mitsubishi Evolution IX - Tech

The Hotchkis bar is hollow, which saves a good deal of weight versus a solid bar of the same diameter, and is adjustable with three different mounting holes. The outermost hole is about 10 percent stiffer than stock, the middle hole 27 percent and the innermost hole 47 percent stiffer. We chose the innermost.

At the same time, we also took the opportunity to maximize the rulebook's allowances and added a rear tower bar. Section 15.2, C allows strut bars that cross left to right on the upper or lower suspension mounting points only. No additional holes may be drilled in the car's body, but interior trim panels may be cut to fit the bar. This means that multi-point bars, such as those offered by Works and Cusco, are not allowed in SP. Our choice was the beefy, one-piece, two-point rear tower bar from Carbing. This provides a direct connection between the rear towers and, because it's constructed from hollow aluminum, comes with a weight penalty of only a few pounds. The Carbing bar also does its job with ease, providing a perfect fit and a more solid rear end. Also, it has no hinges or multi-part construction around which the bar itself could flex.

| Project Mitsubishi Evolution IX - Tech

| Project Mitsubishi Evolution IX - Tech

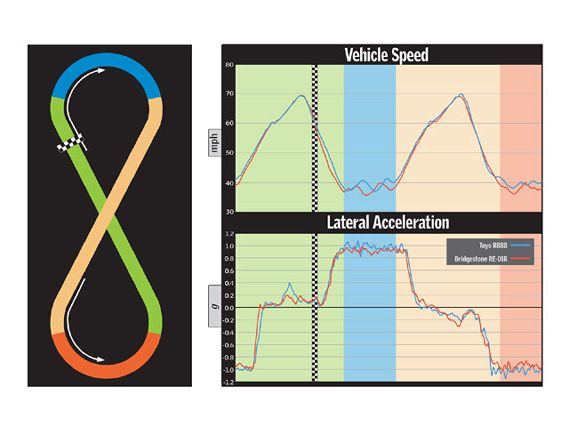

With Project Evo IX buttoned up and ready to go, we cranked the rear shocks to full stiff and hit the test track to see how our autocross prep performed. From a baseline of 0.88g on the skidpad when completely stock, Project Evo IX blasted through our figure-eight course in 25.16 seconds and averaged 0.93g in Street Touring trim-with the Bridgestone RE-01R tires. In Street Prepared trim, with the Toyo R888s, the car reached the magical 1g mark. Even more impressive is the 24.55-second time through the course-which puts it squarely into Ferrari territory-while still using a stock 4G63. The super-sticky R888s also shine under braking, stopping from 80mph to a standstill in just 177 feet-42 feet shorter than what a stock second-gen S2000 can do. This would have placed Project Evo IX fourth in the braking test at last year's USCC.

| Project Mitsubishi Evolution IX - Tech

| Project Mitsubishi Evolution IX - Tech

Already displaying significant speed with an impressive figure-eight time, Project Evo IX could be even faster in SP trim with a more consistent resistance to understeer. Through the course, the front end proves to be skittish on turn-in, with a knife-edge balance between 'on the limit' and violent, shuddering understeer. Get it just right, though, and the car is amazingly fast, although there's still an improvement to be made when entering turns. We're reluctant to try any massively large rear anti-roll bars, out of the fear that Project Evo IX will then start to lift the inside rear wheel during cornering (lifting a drive wheel during steady state cornering is never good), although different alignment settings and a stronger rear limited-slip differential is something we've been looking into. Remember, with an Evo, there's no such thing as too much oversteer.

Cost breakdown MSRP *Toyo Proxes R888, 265/35/18 (each) $320.98 *5Zigen ZR+520, 18x9.5-inch (each) $340.00 *JIC Magic FLT-TAR coilovers $2300.00 *Carbing rear tower bar $450.00 *Hotchkis 24mm rear anti-roll bar $225.95 Project Evo IX performance numbers Stock skidpad lateral-g (g) 0.88 {{{80}}}-0mph braking (feet) 177 Lateral-g (g) Figure-8 course time (sec.) STU (17x8 stock wheel, 0.93 25.16 245/45/17 Bridgestone RE-01R) BSP (18x9.5 5Zigen ZR+520, 1.00 24.55 265/35/18 Toyo Proxes R888)Previous InstallmentsJanuary 2008Part 1: Going cone dodging

May 2008Part 2: Safety myths