| The WORKS 02 sensor housing features OEM-quality cast construction and thermal-barrier coating. Mounting ears allow the use of the stock heat shield. A bigger radius and a larger interior volume provide superior flow. The WORKS housing is compatible with most aftermarket downpipes as well as the stock downpipe

| The WORKS 02 sensor housing features OEM-quality cast construction and thermal-barrier coating. Mounting ears allow the use of the stock heat shield. A bigger radius and a larger interior volume provide superior flow. The WORKS housing is compatible with most aftermarket downpipes as well as the stock downpipe

When we last left Project Evo IX we had just tried out the most basic bolt-on mods and ended up being pretty pleased with the results, picking up nearly 30 whp from stock with just a few hours of work including dyno time. Driveability was improved as well, making it a win-win situation.

Of course, the power increase left us wanting more as our Evo's more than capable chassis didn't flinch with the additional power. Since we were just touching the tip of the proverbial iceberg in our path for more power, we ordered up more parts and got wrenching and testing.

The first thing on our list was to free up the exhaust some more. We were pretty shocked that the exhaust we installed in our last segment of Project Evo didn't make as big of a difference as we suspected. This meant that the stock Evo exhaust isn't that bad and additional restrictions probably existed upstream. We trekked to our favorite shop, Technosquare, and installed a WORKS O2 sensor housing, downpipe, and resonated race pipe to enlarge our exhaust system to 3 inches all the way to our GReddy TiC exhaust system.

| The huge difference in the interior of the stock O2 housing versus the WORKS housing is shown here.

| The huge difference in the interior of the stock O2 housing versus the WORKS housing is shown here.

The WORKS O2 sensor housing replaces the stock cast-iron housing with a new cast housing that makes a more gentile bend out of the turbo for less backpressure causing turbulence while keeping a full 3-inch internal diameter through to the downpipe. Most O2 housings neck down to around 2.5 inches before merging with the downpipe. The WORKS housing's cast construction should be trouble free and its OEM-like fit allows the stock heat shield to bolt back in place for a stealthy install. With the supplied adapter ring, the housing works with the WORKS big downpipe, as well as stock and any other aftermarket downpipe. The housing comes coated with a gold ceramic thermo barrier coating to reduce engine compartment heat and resist corrosion.

| The stock housing exit is much smaller than the WORKS full 3-inch exit. The WORKS housing has the largest exit of any aftermarket O2 sensor housing.

| The stock housing exit is much smaller than the WORKS full 3-inch exit. The WORKS housing has the largest exit of any aftermarket O2 sensor housing.

The O2 sensor housing led to the WORKS big 76mm downpipe. WORKS has taken a lot of care in designing the big downpipe to fit in the tight confines of the Evo IX undercarriage. When the Evo IX was introduced, its ACD torque control system caused fitment issues with many downpipes on the market, an issue many manufactures addressed by dimpling the pipe. Not so for the WORKS unit, it fits perfectly with plenty of clearance. It also fits perfectly with our CROX plate under-chassis brace. The many subtle bends in the downpipe can be seen for this reason. The downpipe is fabricated from 304 stainless steel tubing and has a coating of gold color thermo barrier to reduce heat soaking of the drivetrain. While we were under the car, Technosquare's ace fabricator, Richey Watanabe, welded in a Burns Stainless O2 sensor bung for our wideband sensor to make tuning the car easier and let us leave the stock O2 sensors in place while we tune.

To keep things quiet, we used a WORKS resonated race pipe to link the downpipe to the exhaust. With a 3-inch super free-flowing perforated core resonator, the race pipe is probably the reason why our exhaust system is pretty quiet. In fact installing these free-flowing parts seemed to make our already quiet car less noisy. The stainless steel race pipes matched the rest of our high-quality system.

| The WORKS housing's less severe exit radius is shown here. This gives better flow from the turbo.

| The WORKS housing's less severe exit radius is shown here. This gives better flow from the turbo.

Evos are known to top out the fuel pump's capacity even with bolt-on mods. Although the Evo IX has a higher capacity pump than the Evo VIII, its pump still can get maxed out with bolt-ons. To prevent this from occurring, we installed what is rapidly becoming the industry standard fuel pump for turbo performance applications, a Walbro 255lph fuel pump. The Walbro pump is an easy direct bolt-on that takes only about a half hour to install. Walbro is a QS9000 certified OEM supplier so expect this pump to be extremely reliable.

| The WORKS downpipe clears our WORKS CROX plate with ease.

| The WORKS downpipe clears our WORKS CROX plate with ease.

Since we plan to use our car for track days, we knew cooling was an important issue. To help keep our thermal situation under control, since we removed the radiator to install the O2 sensor housing, we installed an ARC radiator, radiator air guide, and cooling system pressure regulator while we were at it. The ARC radiator is a very high-quality unit, using all TIG-welded construction in the aluminum end tanks to withstand high pressures coupled with a super efficient core. The radiator cools much better than stock but is no thicker-a good deal if you're installing a big turbo. The unit bolts directly in, including the stock fans, making installation a snap.

| The WORKS resonated race pipe is one of the reasons why our car is so quiet.

| The WORKS resonated race pipe is one of the reasons why our car is so quiet.

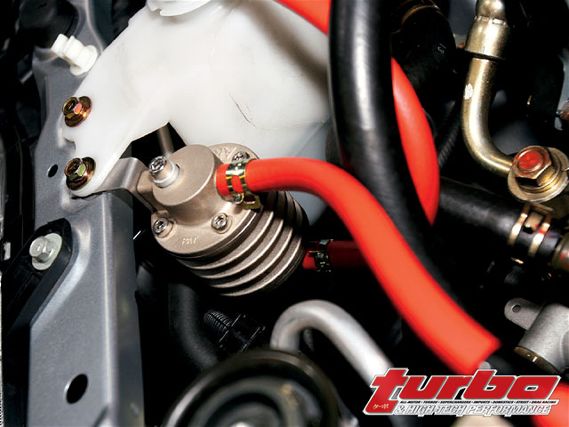

If a cooling system's pressure is kept higher, the boiling temperature increases, with less localized boiling in the head and less cavitations of the water pump. Therefore, the cooling system works much better. To increase pressure, we installed an ARC cooling system pressure regulator between the radiator and the coolant overflow tank. The regulator allows us to adjust the cooling system's pressure from the stock 1.1 bar to slightly over 2 bar.

The ARC air guide is a simple plate that helps prevent air entering the grille opening from pilling over the top of the radiator. Although it's simple in concept, being cut from titanium, it's probably one of the more esoteric parts on Project Evo IX.

| Mitsubishi Lancer Evolution IX - EVO IX Power Tweaks, Part 2

| Mitsubishi Lancer Evolution IX - EVO IX Power Tweaks, Part 2

Since we were upping the pressure of our cooling system, it was prudent to upgrade our coolant hoses as well. Nukabe sent us some of their molded four-ply silicone hoses to evaluate. Silicone has much better temperature-resisting properties than rubber and four-ply is twice as strong as stock units. These heavy-duty features mean that the Nukabe hoses will sport a much longer service life over the stock parts.

With our turbo-back exhaust in place, we returned to the dyno of XS Engineering to test what gain our new parts provided. Once our power levels stabilized, we determined that the new exhaust parts had given us a respectable 15 whp boost, bringing us to 304 whp-not bad for some very simple work. Our knock count, however, started to rise due to the increases in cylinder pressures our free-breathing engine was developing. On an Evo a knock count of more than three means that the ECU is starting to pull timing and the power will fluctuate. This is shown by a rough-looking power trace on the dyno chart as well as registering as knock events on data logging software that XS uses. We were skirting a knock count of three to five at a higher rpm and things were starting to look rough.

| A Walbro 255lph fuel pump ensures that we won't run out of pump capacity soon.

| A Walbro 255lph fuel pump ensures that we won't run out of pump capacity soon.

While the car was strapped down, we added another goodie, an ARC airbox. While studying what worked well on a local Evo forum, the ARC airbox was pretty highly regarded among some of Southern California's local tuners. We also liked it for its bling effect. The ARC airbox is constructed of welded aluminum and simply looks tricker than any other Evo airbox we've seen. Karmen vortex airflow meters like the one used on the Evo are notoriously sensitive to variations in airbox and air filter geometry. Often, simply installing an air intake will mean that an Evo's fuel map must be extensively retuned to maintain the same air/fuel ratio. The ARC box was known for its minimal affect on the MAF's reading, which is another good reason to use it besides looks.

| Our hand-fabricated TIG-welded ARC radiator is a visual work of art that will help keep our engine cool on track days.

| Our hand-fabricated TIG-welded ARC radiator is a visual work of art that will help keep our engine cool on track days.

On the dyno it was hard to determine the effect of the airbox. Although the wideband indicated that our air/fuel ratios were nearly unchanged, the airbox allowed the turbo to spool sooner and increased airflow. The flow increases and subsequent increases in cylinder pressure caused the engine to sport a knock count of over nine, and the ECU was pulling enough timing for the power readings to be awash. The ECU's timing curve would need a retune at this point if we were to see a gain from the airbox. The airbox simply worked too well for the tune at the moment. Another plus, we noticed a reduction of intake air temperature of 12 degrees. We couldn't readily explain this, but many people have observed how the ARC box partially sucks underhood air.

| The ARC cooling system pressure regulator ups our pressure from 1.1 to 2 bar to reduce localized boiling and improve cooling within the engine.

| The ARC cooling system pressure regulator ups our pressure from 1.1 to 2 bar to reduce localized boiling and improve cooling within the engine.

Since we had a relatively high knock count we decided to install XS Engineering's front-mount intercooler before retuning. The XS intercooler has a large tube and fin heat exchanger that's wider and thicker than the stock front mount. The tube and fin core also has a lower fin density than stock. While it would seem like this is a bad thing, the lower density actually allows the cooling air to penetrate more easily into the thicker core, improving efficiency. It also allows more cooling air to pass through the intercooler to reach the engine's radiator, helping to improve overall cooling.

The XS intercooler was a direct bolt-on and only took about a half hour to install while the car was strapped to the dyno. We once again did some pulls and found that the intercooler eliminated knock count across the map and gave us around 8 whp. From this starting point XS Engineering's ace tuner Koji Arai went to work. Koji was able to add quite a bit more timing to our ignition map without increasing knock count and, with a combination of adding more timing and more cam advance to our Mivec system, he was able to extract 9 more hp, leaving us with an impressive 321 whp-a whopping gain of 17 whp just from the intercooler. The power gains were huge and across the board.

| We installed the regulator by the coolant overflow bottle.

| We installed the regulator by the coolant overflow bottle.

We considered adding more timing and fuel or possibly tweaking the boost but when reviewing our data logs, we realized that we were completely out of injectors as we were at 100 percent duty cycle in the last two load columns of our fuel map. Although some tuners in other states have extracted more power with equivalent mods, we feel that our 321 whp is pretty impressive for our exceedingly crappy 91-octane pee water fuel.

Stay tuned; we have some big RC Engineering injectors and more parts waiting in the wings. We intend to see how far the stock turbo and bolt-ons can be taken with California's weaksauce pump gas. Once we max that out, we intend to test a bolt-on turbo upgrade and eventually even bigger and better things!