| Castrol Syntec Top Shop Challenge

| Castrol Syntec Top Shop Challenge

Competition: The act of competing; rivalry for supremacy, a prize; blowing your adversary out of the water in a test of skill or ability. In late 2007, Turbo magazine received some exciting news that Castrol Oil and our wonderful Source Interlink Media proposed an idea of running a "friendly" competition among seven of the top Source Interlink Media publications. The initial rules handed down to each of the teams during the preliminary stages were stated to be as simple, non-competitive event that editors could enjoy. The rules stated each team was to build an engine of their choice, produce the most horsepower and torque per liter, and last throughout the entire event without blowing up. Simple and to the point, right? So they thought. Corporate media had one idea of how to run a challenge and regulate us on how to even the playing field, but for us editors we were playing a completely different ballgame. Funny as it seems, they obviously underestimated the fact that we live and breathe in the automotive performance world and in that world, no one thrives better than us in competition--not to mention the amount of men jacked up on testosterone involved in this event and the sacks that hang between our legs we like to call pride. Elliott Moran, Source Interlink Media's events coordinator, jotted some simple guidelines to abide by as the Turbo magazine team quickly tore into poor Elliott with a battery of questions a month before we finalized our engine and builder.

| Castrol Syntec Top Shop Challenge

| Castrol Syntec Top Shop Challenge

Turbo: How many power adders?

Elliott: Only one and nitrous does count as one adder.

Turbo: What octane grade fuel?

Elliott: 100-octane

Turbo: Can we mix our own fuel?

Elliott: No

Turbo: Can we run a methanol or water injection setup?

Elliott: No

| Castrol Syntec Top Shop Challenge

| Castrol Syntec Top Shop Challenge

Turbo: Will there be an engine teardown after the dyno testing has concluded?

Elliott: No

Turbo: Good Another team chimes in: How will you know their final displacement?

Elliott: You guys are shady. You trying to look for the loopholes already? I'm going to have to revise these rules. What engine is Turbo magazine building and who's the builder?

Turbo: No comment. I'd rather wait to see who our other competitors are using.

Elliott: Why are you being so secretive?

Turbo: It's all part of the game.

| Castrol Syntec Top Shop Challenge

| Castrol Syntec Top Shop Challenge

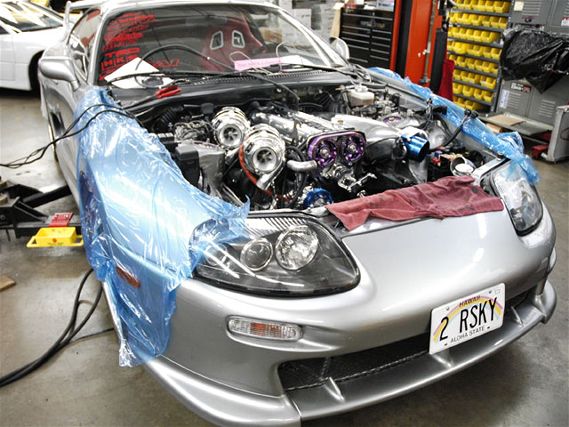

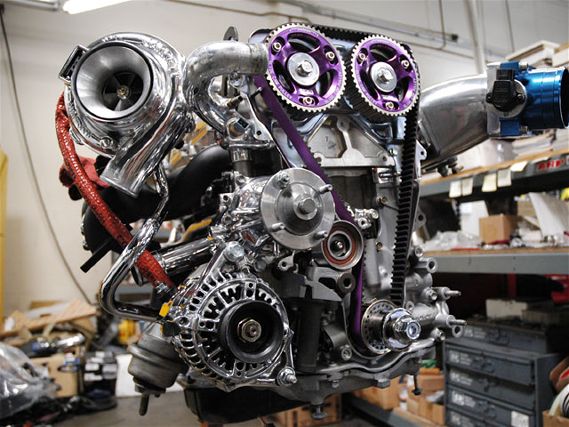

A few weeks after our eventful meeting, we received an updated rules list and a firm warning from our managing editor to take our competitive level down a few notches. Obviously we turned a deaf ear to what Elliott said. While the new interpretations of the rulings continued to have a series of gaping loopholes--which brought smiles to our faces--we searched high and low, finally narrowing our engine builder down to SP Engineering located in the City of Industry. SP Engineering and their knowledgeable staff are regarded as one of the most respected tuner shops in California. Over the past 10 years, SP has built their reputation on tuning and catered to some of the fastest and horsepower hungry vehicles to date. SP Engineering, known as one of the industries trendsetters back in 1996, owned the exclusive bragging rights to building and dynoing their first high-horsepower Supra 2JZ with a simple piggyback fuel management system. The vehicle owned by the now-infamous Ken Henderson laid down 666 whp using a HKS GCC and VPC management system. Eight years after the triple-six power figure, Ken's Supra made headlines on the Nov. '04 cover of Turbo, delivering an amazing 1,110 whp while periodically driven on the streets. SP set the standard again in 1997 using the GCC and VPC layout, delivering 700 whp on another customer's car using a slew of bolt-on products. "We accomplished this power level without even touching the engine internals or even lifting the heads. Back then crazy high-octane gasoline was nearly nonexistent," says Alex Shen, SP Engineering owner and hard-core performance enthusiast. In 2000, SP was up to their tricks once again, benchmarking the 2JZ power limits with 822 whp on a daily driven Supra with the aid of a simple piggyback fuel management unit.

| Castrol Syntec Top Shop Challenge

| Castrol Syntec Top Shop Challenge

From 1,100hp Supras to 1,000hp Skylines, there seems to be no limit to what Alex and his team of mechanics can accomplish. Our initial plans before talking with Alex was to initially build a 2JZ motor in hopes of eclipsing the 1,000hp marker on 100-octane fuel. The five-digit horsepower numbers were a realistic goal that have been tried and tested throughout the years. The 3.0-liter mill seemed to fit the bill for our build but we ran into a series of problems within the competition rules that would affect our winning outcome. If we decided to stroke the factory displacement to a 3.4-liter and were given the penalty of using a forced-induction setup by a multiple of two, we'd divide our target horsepower of 1,100 and get 161.7 hp/per liter. Not a bad number to work with but if our competitors decide to build a 4G63 or SR20DET engine, the 2.0L engine multiplied by 2 and divided by a target goal of 650 hp would net them 162.5 hp/per liter. Close to half our 2JZ horsepower figure but a better horsepower/per liter ratio, which would give them the winning edge.

| Castrol Syntec Top Shop Challenge

| Castrol Syntec Top Shop Challenge

So what is a team hell-bent on taking home the winning trophy and bragging rights to do? It's rather simple. We take our engine selection to the next level and build a noteworthy RB26DETT and decimate the competition. If high-horsepower 2JZ buildups are regarded as the staple within the SP repertoire, believe it or not, their knowledge of the RB26DETT comes in even stronger. "If we target somewhere in the 1,000hp range and receive all the parts we have been talking about, its not hard to make this a realistic goal because in all truth, it's been done before. It's typical to see 1,300 to 1,400 hp cranked out from the RB26DETT. When we built my RB26 a few years back I didn't even go crazy on the engine so weren't really pushing the engine. My R33 put down 980 whp and was dynoed while running a hollinger transmission so I'm not even worried about having to push this motor." With a smile and look of confidence Alex continues by saying "Hirofumi Kondo, our chief mechanic was working at Blitz Japan for eight years before he began full time at SP Engineering. Turbocharging, supercharging, and computer tuning is Hiros specialty so I have full confidence in him. Hiros been installing and tuning the HKS V-Pro with exceptional knowledge because he's been there and done that for some time now with an advantage of over four years of tuning ahead of U.S. tuners."

| Castrol Syntec Top Shop Challenge

| Castrol Syntec Top Shop Challenge

While all details on the engine aren't finalized as this article goes to press, one thing we're certain is that the 2.6L mill will be stroked to a 2.8 displacement and for good reasons. The theory behind stroking the RB rather than going with the factory displacement comes down to the factory crank. "The crankshaft isn't fully counterweight," Alex says. "When you buy a stroker kit it comes with a full counterweight crankshaft, but not from factory not like the 2JZ. That's the weak point of the RB. The powerband with the RB26DETT possesses a broader scale power range compared to the 2JZ powerplant at the same horsepower level. If you overlap a RB26 to a 2JZ dyno sheet it will become apparent the major differences with the power curve. The 2JZ powerband is so short; it's crazy in comparison to the RB26DETT." This becomes a major factor when determining the top point's leader in the "Power Under the Curve" category for the Castrol Top Shop Challenge.

| Castrol Syntec Top Shop Challenge

| Castrol Syntec Top Shop Challenge

One word of advice to our competitors: We're in it to win boys, so you best pack your bags now before it's too late. Stay tuned as we begin our RB26DETT buildup in the next issue.

Castrol Top Shop Challenge Rules

Competitors:

Eurotuner magazine

Import Tuner magazine

Lowrider magazine

Modified magazine

Sport Compact Car magazine

Super Street magazine

Turbo magazine

| Castrol Syntec Top Shop Challenge

| Castrol Syntec Top Shop Challenge

Rules:

A. Engine Setup

1. Only a production engine found in a production-based car will be allowed as your engine for competition.

2. Only one forced-induction system permitted (turbo or supercharger, NO nitrous oxide). Factory turbo or superchargers count as the one forced-induction system.

3. No methanol, auxiliary fuel or water injection is allowed.

4. Engine management is based on what the teams are most skilled at. Final tuning runs will be performed on an engine dyno and so a mobile wiring harness is required. Do not show up with your engine in a car.

5. Parts must be provided by the competitor. Should any parts be outsourced from other manufacturers, individual competitors cover any additional expenses or negotiate individual sponsorships. The object of the competition is to ensure most parts are obtainable to the reader.

6. Custom parts will be allowed. Aftermarket parts used can be modified.

7. Heat or cryo treating and thermal coating is permitted.

8. No welding of cylinder head to the block.

9. Testing will be done with no muffler but header/manifold choice must fit a production chassis.

B. Fuel and Oil

1. Engines will be required to run only on a spec 100-octane gas. We will not allow any type of additives or oxidizers to make any type of special blend of gasoline. Gas will be distributed at our test location with fuel testing done before and after your dyno session.

2. Spec Castrol oil of the shop's requested weight will only be used. No oil additives will be allowed.

C. Format1. End results will fall within the following categories:

∙ Peak horsepower and torque per liter of displacement. Turbo/superchargers are given a multiplier of two (a 3.0L turbo motor makes 600 hp, 600 hp 3.0-liter x 2 multiplier = 100 hp per liter) Naturally aspirated motors receive no multiplier. Exception: Rotary motors (13B, 20B etc... will have their displacement doubled as well)

* Power under the curve

* A 30-minute drive cycle

* Build quality/craftsmanship (judged by a panel of three experts)

2. All of the above mentioned categories will be based off of one dyno run on a reasonable ramp rate or engine load of our choice.

3. A 100-point system will be used for horsepower/torque, power under the curve and build quality. You'll get 100 points for completing the 30-minute drive cycle. If the motor doesn't complete the drive cycle you'll receive 0 points.

The highest combined point total will determine the winner.

4. Each shop will need to have their engine tuned before they come to the competition. Tuners will be allowed 45 minutes before their first official run to fine-tune.

5. Once all tuning is complete, a final run for the end result rests on the team. Final test run will be the same day as the tuning performed of the engine. Air temp and barometric pressures will vary from day to day but if possible we'll run corrected numbers at sea level. Following the peak power dyno runs will be the 30-minute drive cycle. Your motor will need to last the entire competition to be able to win.