| Project Ford Focus SVT

| Project Ford Focus SVT

Former Associate Senior Editor Jared Holstein can dance like you can't believe. He can drive a car right to the edge of disaster while turning amazingly fast lap times. He's also cultured, with enough knowledge of fashion, art, music, fine food and drink to make the Queer Eye guys run for their contracts. The only problem is, he has zero mechanical sympathy and a definite knack for turning all things mechanical into a scrap heap at the drop of a hat.

Before he left SCC to expand his journalistic horizons, Holstein took our turbocharged Project Ford Focus SVT out for a spin and, as a going away present to us, did quite a number on the Zetec engine's bottom end. Because Holstein is Holstein, we forgave him for the ton of rebuilding work, as this was not an intentional act, but rather something as natural to him as, well, breaking stuff.

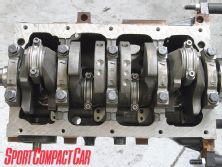

| A Holstein'd piston from Project Focus SVT. The engine must have been detonating like a machine gun, but Holstein swore he heard nothing and the car simply stopped running. It's hard to tell, but the OEM piston is a pretty stout piece with hard anodizing and low friction skirt coatings.

| A Holstein'd piston from Project Focus SVT. The engine must have been detonating like a machine gun, but Holstein swore he heard nothing and the car simply stopped running. It's hard to tell, but the OEM piston is a pretty stout piece with hard anodizing and low friction skirt coatings.

We learned a harsh lesson in automotive reality about the combination of a 10.2:1 compression ratio, cast pistons, a turbocharger, crappy 91-octane California gas and an on-the-fritz MAF being right on the edge. Throw in a driver with a lead foot and an apparently deaf ear towards the sound of detonation, and you get one very dead motor. A postmortem examination found completely nuked pistons. The ring lands were more than just fractured or pinched (the normal sure-fire signs of detonation damage), they were completely gone. The rings were not just stuck and scored but melted, with large spans missing. Even the skirts were melted. And it wasn't just the pistons. The block was scored so badly that it couldn't be saved, even by an enthusiastic overbore.

We had never witnessed such destruction before. Although we were left with a big repair task, we made a commitment to bring Project Focus SVT back, so that, one day, it might finally face off with a Mustang Cobra on the track. FocusSport, one of the leading tuners of the Focus platform, generously stepped forward to help us put our dead player back together.

| One of the most apparent differences between the stock piston (right) and the JE piston (left) is that the JE piston has a dish in it to reduce the compression ratio to a more turbo-friendly 9.0:1.

| One of the most apparent differences between the stock piston (right) and the JE piston (left) is that the JE piston has a dish in it to reduce the compression ratio to a more turbo-friendly 9.0:1.

The factory Ford Zetec engine is a high performance powerplant with a strong bottom end and a tough cast iron block. The Focus SVT version has beefed-up pistons, crank and rods. The stock internal components are usually reliable until about 280 to 300bhp. Untouched, the engine makes a respectable 170bhp with a 10.2:1 compression ratio-not a forced induction-friendly number. Not that that matters, since those pistons are now just paperweights. To give us a more forgiving margin, considering our home state's penchant for having some of the worst fuel in the nation, we decided to reduce the compression ratio to a more turbo-friendly 9:1, courtesy of some forged pistons from JE Pistons.In order to avoid terminal engine issues, we were compelled to obtain some of the toughest possible pistons. Most forged pistons are manufactured from either 2618 or 4032 aluminum alloy. Both have advantages and disadvantages, depending on application. Racing engines usually require stronger low-silicon 2618 alloy, while less demanding applications favor the greater silicon content found in 4032 alloy.

Our pistons started as blanks, forged from 2618 alloy. This alloy is extremely ductile and strong, perfect for the stress and pounding of a forced induction set-up, or dealing with Holstein. The primary disadvantage is a greater coefficient of thermal expansion. When exposed to heat, a piston made of 2618 alloy will expand approximately 13 percent more than its 4032 counterpart. To accommodate the additional expansion, more initial piston-to-wall clearance is necessary. Extra clearance results in more piston noise at cold start-up, but this effect diminishes as operating temperatures are reached.

| Although the stock rod (top) is well made, the Eagle rod (bottom) is much stronger and lighter, due to its H-beam construction, superior materials and ARP rod bolts.

| Although the stock rod (top) is well made, the Eagle rod (bottom) is much stronger and lighter, due to its H-beam construction, superior materials and ARP rod bolts.

JE Pistons' extensive engineering experience and tight manufacturing tolerances result in a precisely shaped piston skirt profile. A typical skirt profile will incorporate a 'barrel shape' (when looking at the piston side-on), with more clearance at the heat-soaked top of the piston, less mid-skirt, and an inward taper at the base. This design optimizes clearance across the skirt face, based on the location of heat. JE pistons feature some of the tightest bore clearance specifications of any low-silicon piston. The correct amount of clearance will reduce 'slap' against the cylinder walls for less wear and quieter operation. The pistons are also optimized for strength and lightness-ours weigh just 299 grams each.

We used shelf part number 185915. These pistons feature many of JE's technically advanced designs, such as double forced pin oilers, contact reduction and accumulator grooves. Contact reduction grooves are small waves machined into the contact face of the top ring land. They serve as a labyrinth baffle to help buffer shock waves caused by detonation, minimizing ring flutter and damage. This design also gives the aluminum room to expand and prevents scuffing against the cylinder wall.

| Before assembly, all the parts were cleaned and laid out on a clean sheet of cardboard. Genuine Ford gaskets, seals and bearings were used.

| Before assembly, all the parts were cleaned and laid out on a clean sheet of cardboard. Genuine Ford gaskets, seals and bearings were used.

The accumulator groove is possibly the most beneficial feature. This V-style groove is located on the second ring land between the top and second rings. It acts like a reservoir for high-pressure combustion gases that leak past the first ring, reducing the pressure that can lift the top ring from the base of the groove and cause it to lose its seal. This difference is most significant at high revs.

Double forced pin oilers feed the wrist pin with a steady supply of oil pumped in from the oil ring groove. Proper wrist pin lubrication is crucial, especially in engines using forced induction. The pistons also use a thick-walled, straight-diameter, high-carbon steel piston pin, a better choice to reduce flex in high-load, forced induction applications. The pin is held in place with Spiro-Locks, probably the most secure pin anchoring system available.

The top ring land is made thicker, to increase land strength and move the top ring away from the intense environment of the combustion chamber. This is the opposite strategy of the damage-prone OEM piston that features a short top ring land to reduce hydrocarbon emissions. The tops of our pistons use a 6.9cc dish to reduce compression ratio. The dish design puts flat areas of the piston top in line with the quench pads in the cylinder head. This causes turbulence in the mixture as the piston reaches top dead center, resulting in complete burn and a reduced likelihood of detonation. This type of piston top configuration is called a reverse deflector.

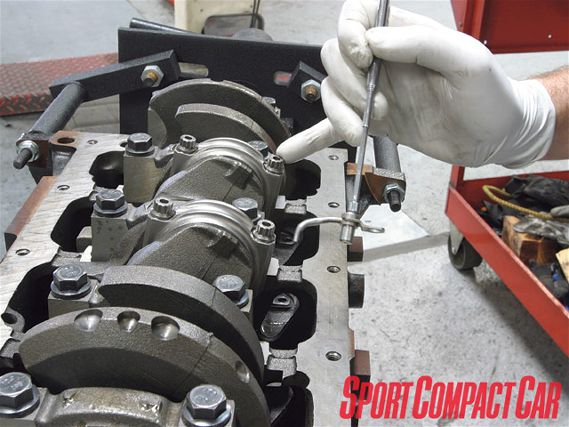

| The main bearings were placed into the saddles in our block and the bearing surfaces covered in fresh oil.

| The main bearings were placed into the saddles in our block and the bearing surfaces covered in fresh oil.

JE Pro Seal rings were also selected. They're significantly thinner than the OEM ring set. This design results in less radial tension, therefore less friction and more power. The thinner profile also means that the rings are lighter and less prone to inertial flutter from the base of the ring groove. Plus, they won't lose their seal at high revs. The chrome-faced top and oil rings are perfect for our iron bores.

JE makes the 185915 pistons for 85mm bore sizes. This is approximately 0.007-inch larger than the standard Zetec bore. The design incorporates a piston-to-wall clearance of 0.004-inch. Honing our bores 0.007-inch oversize to exactly 85mm is all that is necessary to prepare them properly. We handed our block to Cosworth Engineering in Torrance, California, to make use of its world-class machining facility.

To hang the pistons, we needed to find a stronger connecting rod. We chose Eagle for its ESP rods, forged from a high nickel and chromium 4340 steel alloy. The nickel and chromium give the steel a high tensile strength and a much improved fatigue resistance over regular high carbon, and even chromoly steels. A good feature is that the rod is forged in two pieces, with the cap forged separately. This allows it to have the metal's grain flow in a circle around the big end bore. With this forging method, there is greater strength and less distortion of the rod's big end under load. Typically, rods are machined from a one-piece forging, where the grain flow is along the length of the rod. When the big end of the rod is machined, the grain is interrupted by the hole.

The rod's beams are machined in an H profile. This profile is stiffer, putting more material where it is needed for strength and none elsewhere. With this sort of construction, an Eagle rod is typically about 100 grams lighter that most stock rods. In the machined valley of the H is a small rib at the base. This enhances the beam's strength.

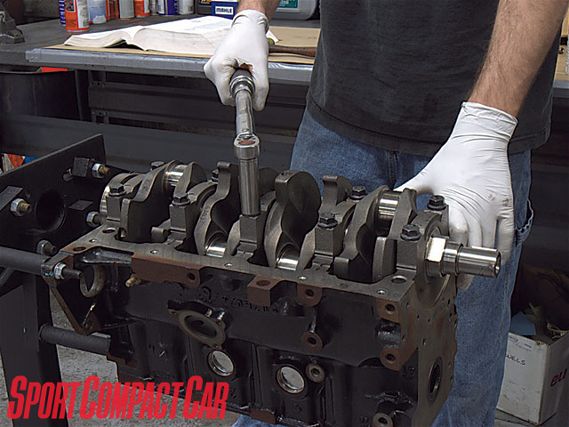

| Before the connecting rods and pistons were installed, we installed the piston coolers. These are jets that spray oil on the undercrown of the piston at high revs to help it stay cool. Although standard in the SVT engine, piston coolers are helpful for any turbo or high compression engine.

| Before the connecting rods and pistons were installed, we installed the piston coolers. These are jets that spray oil on the undercrown of the piston at high revs to help it stay cool. Although standard in the SVT engine, piston coolers are helpful for any turbo or high compression engine.

Piston pin oiling holes are drilled upwards at an angle towards the pin. This is unlike the standard practice, where pin oiling comes from a single hole drilled at the top of the rod. This hole significantly weakens the small end of the rod. By putting two smaller holes at the bottom, at the less stressed portion of the pin boss, Eagle has a much stronger part.

The rod's entire surface is machine finished. This ensures consistency in both dimension and weight. After machining, the rod is subjected to shotpeening, a process where it is bombarded by hard steel shot at high velocities.

Shotpeening helps refine the metal's grain over the surface of the rod, creating a finely grained compressed layer of steel where cracks have a hard time propagating. Shotpeening improves fatigue resistance in most steel parts by over 100 percent.

The piston pin bushing is tough silicon bronze, one of the most wear-resistant bushing materials available. As the rod bolts are the most critical part on the connecting rod, no expense was spared. Eagle uses genuine ARP 8740 7/16-inch rod bolts for all its sport compact series. These have a tensile strength of over 230,000psi, many times stronger than the factory bolts. Altogether, each new piston, pin and rod assembly weighs 1.9 pounds. The far weaker stock components weigh 2.35 pounds.

| The main caps were installed with the stock bolts and torqued down in several steps to the factory Ford specs.

| The main caps were installed with the stock bolts and torqued down in several steps to the factory Ford specs.

Once the block machining was complete and the parts lined up, FocusSport assembled our motor's bottom end, making doubly sure it would hold up if Holstein ever found his way behind the wheel of Project Focus SVT again. All critical clearances were double-checked and the bearings replaced with genuine Ford parts. As the stock SVT crankshaft is a beefy fully counterweighted forged part, FocusSport retained it.

With our bulletproof bottom end cinched up, next time we'll be ready to bolt on our Cosworth cylinder head, Quaife-equipped transmission and stuff it all back into the chassis. That is, just as soon as we kill all the black widow spiders that have claimed our Focus as their home for the past two years.