| Project Subaru STI Part 6

| Project Subaru STI Part 6

In part 4 of Project STi we got some pretty good results with some tuning by XS Engineering that nicely complemented our bolt-ons. However, we were stymied in our efforts to extract more power by a slipping clutch. Also, we noted that our rather high mileage motor was starting to burn a little oil, probably from the wear of over 100k miles that was put on it as a daily driver. Many of these miles also happened to be grueling track ones. No doubt that an engine rebuild was going to be needed in our plans soon, but we still wanted to pursue more power with the stock engine first.

Our first problem to fix was the clutch. What we wanted in a clutch was a tall order. We wanted a clutch that could withstand over 400 whp in an all-wheel-drive vehicle, a punishing application to begin with. We also wanted good streetability, since this car sees daily use. No juddering on/off switch metal discs and super stiff pressure plates were going to work here.

| The ACT clutch disc uses an organic friction material, a spring hub and a marcel spring to make it a smooth operator on the street.

| The ACT clutch disc uses an organic friction material, a spring hub and a marcel spring to make it a smooth operator on the street.

For a cure to our clutch woes we consulted with Daryl Sampson of Advanced Clutch Technology. ACT supplies a wide range of clutches for most popular sport compacts, from heavy duty to race applications. Knowing our penchant for road racing, Daryl suggested a heavy duty disc and pressure plate coupled with ACT's super light ProLite flywheel.

The heavy-duty pressure plate features a clamping force of 35 percent stiffer than stock while maintaining a reasonable pedal effort and release travel. This means that your left leg won't become overly buff causing you to walk in circles, and you won't need knee surgery if you have to drive in bumper-to-bumper traffic.

The clutch disc features a copper-woven, organic friction material for higher burst strength and improved heat dissipation, with a marcel spring and a sprung center hub for smooth engagement characteristics. The clutch is conservatively rated for a maximum of 411 lb-ft of torque, an amazingly high number for its daily driver smoothness.

| The oval holes machined around the ProLite flywheels' periphery greatly reduce its inertia.

| The oval holes machined around the ProLite flywheels' periphery greatly reduce its inertia.

We bolted the clutch to a ProLite Flywheel. The ProLite is forged from high strength chromoly steel. Forging is a superior way to make flywheels and results in a flywheel with superior burst and wear characteristics. Its one-piece construction is probably stronger than your typical two-piece aluminum light flywheel, and it can be resurfaced - unlike some very thin steel flywheels.

The ProLite has a series of lightening holes machined around its periphery between the friction surface and the starter ring, where it makes the biggest difference in inertial weight. Because of this, a ProLite feels like a lighter flywheel than its 11.1 pounds suggest.

We were impressed with this combo's smoothness; and the light flywheel makes the car much more responsive to throttle input and reduces the time for the turbo to spool. Our car felt springy, light and eager to go with this combination. We were also pleasantly surprised how easy it was to drive, even in bumper-to-bumper traffic. Of course, instead of going back to the dyno, we decided to increase the power.

| The ACT pressure plate is a hard-clamping pull-type diaphragm spring that has a 35 percent higher clamping force, but is still easy on the left leg.

| The ACT pressure plate is a hard-clamping pull-type diaphragm spring that has a 35 percent higher clamping force, but is still easy on the left leg.

Our next upgrade was a simple one: we installed a set of Unorthodox Racing's underdrive pulleys. The Unorthodox pulleys got rid of several pounds of rotating weight off of the engine and reduced parasitic drag by slowing the drive speed of the power steering, alternator, water pump and air conditioning. Usually this equates to 3 to 6 wheel hp and improved throttle response.

The Unorthodox pulleys are machined from 6061 T6 aluminum billet and weigh in at a feathery 3 pounds, saving over 6 pounds of rotating weight. Unfortunately, we installed them at the same time as the rest of the parts covered here, so we didn't get an individual dyno result from them.

When looking at the stock turbo, we knew there would be quite a bit of power to be found by upgrading it. The tiny stock IHI VF39 turbo was too small for the 2.5 liters of displacement behind it. Our goals were also rather difficult here.

| Unorthodox Racing pulleys are machined from 6061 aircraft aluminum billet and weigh only 3 pounds for an entire set.

| Unorthodox Racing pulleys are machined from 6061 aircraft aluminum billet and weigh only 3 pounds for an entire set.

Since at this point Project STi is more to show easy ways for the average guy to get power rather than showcase the ultimate in performance, we wanted to stick to strictly bolt-on turbos. No huge turbo with a fancy angle-mount and an external wastegate - at least not yet. We wanted to show the potential for a simple bolt-on that could bolt to our DC uppipe or the stock system with a no-fuss internal wastegate, again compatible with both stock and typical aftermarket parts.

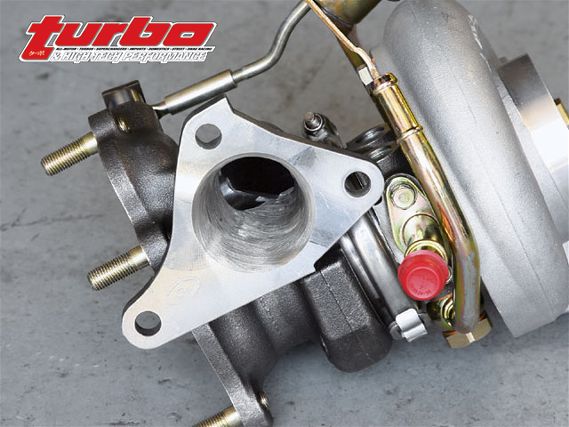

After much research we turned to Forced Performance for one of their Green Turbos. The FP Green turbo features a huge Mitsubishi TDO6 compressor cover that houses a custom machined compressor wheel with an inducer of 2.123 inches and an exducer diameter of 3.00 inches. This wheel flows a whopping 730 cubic feet per minute (CFM) over the stock IHI's paltry 470 CFM. The compressor housing has a 3-inch radiused inlet and a 2-inch outlet.

On the exhaust side, a big Mitsubishi turbine wheel with an exducer diameter of 2.315 inches and an inducer diameter of 2.650 inches is used. A Mitsubishi turbine housing with an inlet area of 7cm squared is used, up from the stock 6cm squared. This is the Mitsubishi way of specing out turbine housing size, compared to the A/R figure that is quoted for most other turbos. A bigger area of exhaust housing inlet will flow more and make more power, but tend to have more turbo lag.

| Looking down into the FP turbine, you can see the porting and the enlarged and unshrouded wastegate bypass port.

| Looking down into the FP turbine, you can see the porting and the enlarged and unshrouded wastegate bypass port.

The turbine housing inlet is ported out to 52mm, the size of the typical aftermarket bigger diameter uppipe. The bypass port for the internal wastegate in the exhaust housing is unshrouded and enlarged to improve flow and help reduce the chances of boost creep.

Unlike many "upgrade" turbos, the FP Green uses the correct compressor and turbine housings for the wheels with the correct volute and diffuser configuration. This ensures that the wheels work at their design efficiency. Many upgraded turbos put huge wheels in the stock housings and if you look inside the housing of a turbo upgraded like this, the big wheels carve into the housings diffuser, sometimes leaving the housing with little or no diffuser at all. These sorts of upgrade turbos usually have a compressor efficiency of less than 50 percent and have compressor discharge temps of over 300 degrees! Not the best thing for your motor.

| To increase longevity at higher boost levels, the FP green uses the much larger thrust bearing - shown on the left.

| To increase longevity at higher boost levels, the FP green uses the much larger thrust bearing - shown on the left.

Turbines upgraded like this often have a less than optimal approach angle for the exhaust gasses impinging on the turbine wheel. This kills the turbine efficiency. It produces a wheel that flows well, but produces much less shaft power - making for a very laggy turbo. A poorly upgraded turbo often has only slightly more power than stock, and sometimes even less with quite a bit more lag. Forced Performance uses the proper housings for its bigger wheels so the compressor and turbine can function as designed.

The center section of the turbo is reworked as well to help reliability at higher boost pressures with FP's vastly improved thrust bearing. Thrust bearing failures in my experience are the most common ones experienced in well set up high-performance turbo systems, especially when running over 15 psi of boost. FP gets around this by doubling the oil flow to the thrust bearing and installing a thrust bearing with 3x the surface area as stock.

| The big compressor housing on the FP turbo means the TGV valve actuator must be removed.

| The big compressor housing on the FP turbo means the TGV valve actuator must be removed.

Finally FP changes the wastegate actuator with a part with a cracking pressure of 15 psi vs. the stock actuator's 6 psi. This usually results in much faster spool and better throttle response as the wastegate will stay closed until the boost pressure is closer to its rated pressure.

The FP turbo came ready to bolt on with all of the required fittings needed to adapt oil and water lines to its center section. We did, however, need to remove the stock TGV valves from the intake manifold. TGV valves are devices that Subaru has installed in the STi's intake manifold. They are butterfly valves that induce a swirl into the intake flow at partial throttle for emissions purposes. The trouble is that these valves also block about 40 percent of the manifold's intake port; and the actuator for the valves hits the compressor housing of the FP turbo.

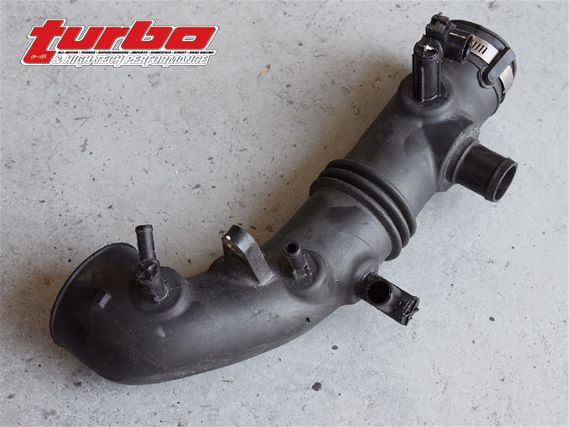

| The stock intake pipe is too small in diameter to bolt up to the FP Green compressor housing.

| The stock intake pipe is too small in diameter to bolt up to the FP Green compressor housing.

We removed the valves and the actuators; welded up the holes for the valve shafts; and ported out the passages for the valves, converting the intake manifold to a straight unobstructed passage to the cylinder head. From what we have been told, this operation frees up about 5 to 8 wheel hp and improves throttle response. From looking at the blockage the TGV valves create, we believe it.

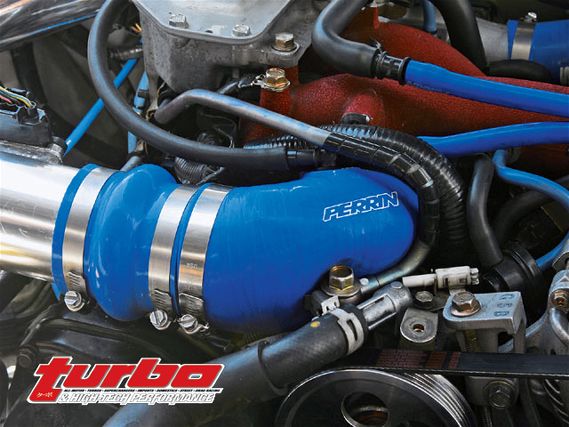

The 3-inch inlet of the FP turbo presented another issue: the stock intake hose would not connect to it. The stock inlet was also a highly restrictive piece, full of kinks and necked-down areas that would restrict flow. At FP's recommendation we contacted Perrin Performance for one of their inlet hoses specially designed for the FP Green's 3-inch inlet.

The Perrin inlet is molded from thick multi-ply silicone. It eliminates the kinks and neck-down effect, improving flow. It also connected directly to our XS Engineering air intake with little effort.

| Perrin's 3" intake pipe saves the day. It is much larger in diameter and it's obvious that it's going to flow a lot better.

| Perrin's 3" intake pipe saves the day. It is much larger in diameter and it's obvious that it's going to flow a lot better.

Perrin also supplied us with several of their pieces to help us with our performance goals. First was their 3-inch stainless steel downpipe. The Perrin downpipe has a divider that separates the flow from the turbine and the wastegate. The wastegate discharge flow is separated from the turbine flow and reintroduced into the exhaust farther downstream. This improves flow for both the turbine and the wastegate port and helps with turbo spool and response.

Subarus, especially track driven ones, have a problem with oil consumption and blow-by contaminating the intake charge. To prevent this, we installed one of Perrins' catch cans on our car. The Perrin can separates out oil from the blow-by gases and traps it before it can contaminate the intake charge. This helps reduce oil consumption and reduces the chance of detonation due to oil contamination of the intake charge.

| The Perrin intake pipes' molded construction makes it able to fit its large diameter in the confines under the STi's intake manifold.

| The Perrin intake pipes' molded construction makes it able to fit its large diameter in the confines under the STi's intake manifold.

When running our racing downpipe with no cat at the track, we used to get an annoying check engine light for an unresponsive rear O2 sensor. We installed Perrin's rear O2 sensor emulator to get rid of this problem. The Perrin emulator fools the ECU by sending the ECU a simulated signal of a properly working 02 sensor. No more check engine lights.

To help us stay cool on the track even on typical 120-degree Willow Springs days, we installed an ARC radiator and an XS Engineering 160 degree thermostat. The ARC is a racing all-aluminum radiator with nearly twice the cooling capacity as the stock unit. Now our coolant temps stay within acceptable ranges. We feel that running our engine hot on the track probably contributed to its current oil burning state. Now our water temps will stay more stable.

After XS Engineering reflashed our ECU with one of their off-the-shelf programs for a parts combo identical to ours, it was time for us to go out and see what she could do.

| Perrins' downpipe features 304 stainless construction, TIG welding and a great fit.

| Perrins' downpipe features 304 stainless construction, TIG welding and a great fit.

With our new group of parts, we were more than impressed with our test drive. The acceleration pinned the driver to the back of the seat, the nose of the car reared up and the steering got light. Sometimes there was wheelspin from the four tires. It was amazing. It felt like a genuine 12-second street car. It felt like we gained 50 to 60 more hp. The negatives were minimal. Due to our engine's large 2.5-liter displacement, the close spacing of our 6-speed gearbox and our light flywheel, the increase in turbo lag due to our larger turbo seemed minimal. Our drivability remained so good that our package seemed like it would be something the factory would offer in a higher output STi option.

The gains were so great that we were mulling over suspension changes to match the suspension to our newly increased power. Unfortunately, due to scheduling, many weeks and a few track events passed between our installation and the dynoing of our parts. The owner of the car was complaining that his car felt weaker and was burning more oil. We drove it and the car did indeed feel weaker.

We rushed a dyno session with XS Engineering, and found that we were only a few hp greater than our previous test. To be fair to Forced Performance and Perrin, we are going to freshen our tired motor and try to get some new test number more in line to what we felt when we first installed the turbo in our next installment.