| Project Scion tC - 2005 Scion tC

| Project Scion tC - 2005 Scion tC

So far, Project tC has shown there is performance hope for the Scion coupe. In fact, there's a lot of hope. The last round of simple suspension bolt-ons yielded near Evo-rivaling handling numbers. Then we heard that the Celicas were being dropped in favor of tCs at this year's Toyota Grand Prix of Long Beach (see page 48). We figured if Toyota is willing to throw a bunch of celebrities into race-prepped tCs for their annual Pro/Celebrity Race, we might be on to something too (although this may not be an endorsement of the car's performance potential, but rather a clever way of disposing of annoying D-list celebrities like Frankie Muniz).

But numbers aren't everything. Although we realized huge improvements from just basic bolt-on parts, the tC is nowhere near as rewarding as many of our other project cars. We have to work out how to add some feel and character into the chassis, which is something far less measurable. In this installment, we'll try to fix the part of the tC we hate most, the brakes.

Braking Torque And Brake BiasBetter braking is a matter of tire selection. Since tires are what ultimately stop a car, the first place to look for shorter stopping distances is with stickier rubber.

For some cars, however, there's a way to cheat and get a little more braking out of the same tires by making the rear tires do just a little more work. In general, stock brake systems are designed to be front biased, meaning the braking torque in the front is a lot more than in the rear. Consequently, the front tires bear most of the stopping load. When ABS kicks in, the front tires are at their friction limit, but the rears most likely still have grip. By adding more rear brake bias we can take advantage of additional rear grip not currently being used. To do this requires taking an engineering perspective, so put on your pocket protector and brace yourself.

| Powerslot's Plus kit for the tC uses two-piece, 12.8-inch vented front and 12.5-inch rear rotors compared to the stock 10.76-inch front and 10.5-inch rears. Powerslot includes CNC aluminum caliper spacer brackets and all additional hardware.

| Powerslot's Plus kit for the tC uses two-piece, 12.8-inch vented front and 12.5-inch rear rotors compared to the stock 10.76-inch front and 10.5-inch rears. Powerslot includes CNC aluminum caliper spacer brackets and all additional hardware.

To start, any engineer worth his slide rule needs an equation-we're helpless without them. In an ideal world, braking torque, or how much your caliper can resist the twisting motion of your wheels, is approximated with a fairly simple equation:

TW = PS x AP x x 2 x RE

Braking torque, TW, is the product of the hydraulic pressure in the brake lines, PS, multiplied by the total piston area, AP, (for a sliding type caliper or one-half the total area of a fixed caliper) multiplied by the friction coefficient of the pads and rotor surface, , multiplied by the effective radius of the clamping force, RE. Everything is multiplied by two since there's another half of the caliper pushing on the opposite side of the rotor.

Without substituting in numbers, this equation tells us some simple things. The available torque to resist turning is a matter of line pressure, total area of the pistons (not number of pistons), friction material (pads), and size of the rotors. By increasing any one of these variables at the rear we can increase the braking torque and thus bring more braking bias to the rear.

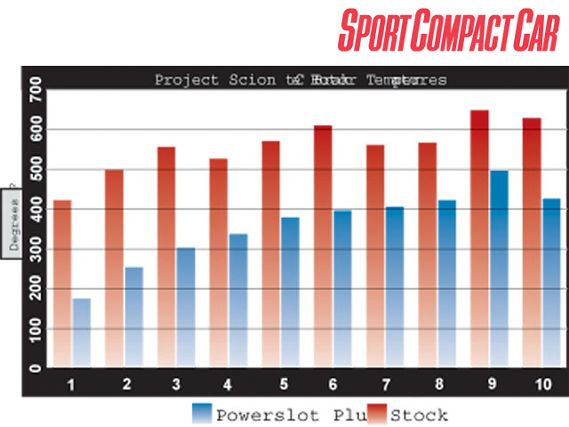

| Front rotor temperature over 10 consecutive runs.

| Front rotor temperature over 10 consecutive runs.

Now, merely mention changing brake bias to a bunch of car geeks, and there is always some smart ass who will call for a proportioning valve. Wrong. Although proportioning valves can be used to adjust the ratio of front and rear hydraulic pressure, the way they adjust pressure is by pinching off the line pressure going to the front or rear, depending on where you place the valve. In other words, you can only increase rear bias by pinching off pressure going to the front, which reduces total clamping force in the front, which is stupid since you're sacrificing a lot of braking torque for a little more balance. Proportioning valves should only be added to the rear brake circuit to add front bias-which isn't what we want.

Since increasing the line pressure or piston sizes can't be done without significant cost and headache, we're basically left with using larger rotors and better pads to control brake bias. We picked up Powerslot's bolt-on plus-size brake kit, which pairs the stock calipers with aluminum spacer brackets and larger 12.8-inch and 12.5-inch rotors in the front and rear, respectively. This 18.9 percent increase in overall radius in the front and 19.3 percent in the rear roughly equates to the same percentage increase in brake torque, assuming nothing else changes. (The effective radius is usually the centerline of the brake pad. Assuming this, the percentage increase in effective radius is just slightly less than the increase in overall radius.) And since braking torque increased more in the rear than the front, the bias has been shifted just slightly to the rear.

Powerslot offers a more aggressive set of Hawk pads with a higher coefficient of friction () for only the front calipers with their kit. Even though this would have provided better feel and been more tolerant to aggressive driving, using aggressive front pads with the stock rear pads would have thrown the brake bias toward the front, undoing any advantage we might have gained. Instead, we used EBC's Greenstuff pads, which are available for both the front and rear calipers. Assuming EBC uses the same front and rear pad material, we would at least have an equal increase in brake torque so no change in bias.

| The new hardware weighs 18.7 pounds in front and 11.8 pounds in the rear. Five pounds heavier in front and 3.5 pounds heavier in the rear. (Yes the scale says 12.0 because it didn't get zeroed.)

| The new hardware weighs 18.7 pounds in front and 11.8 pounds in the rear. Five pounds heavier in front and 3.5 pounds heavier in the rear. (Yes the scale says 12.0 because it didn't get zeroed.)

We were so proud of ourselves for working all this out and were just about to try different combinations of stock, Hawk, and EBC front pads with the EBC pads in the rear to see which setup had the best balance, when Scion's engineers pointed out that the tC has electronic brake force distribution control.

As it turns out, like many Toyota parts, the tC's braking system is shared among other Toyota platforms. Even more interesting is that it is more cost effective for Scion to use these Toyota parts with the extra bells and whistles instead of developing new, less complicated parts. This explains why the budget-priced tC has Electronic Brake-force Distribution (EBD) and Brake Assist (BA). EBD acts as an automatic proportioning valve and controls bias on the fly, sending stopping power where it's needed. BA automatically applies full braking power when a panic stop is sensed via rapid pedal movement, such as when the driver stabs the brakes. So if your front tires reach their ABS threshold first, the EBD system will apply more braking pressure in the rear until the rears are at the edge of locking up. So much for all our efforts at adding more rear bias. All we had to do was increase brake torque everywhere and let the car's electronics do the rest.

| Installing the Powerslot Plus brakes is a matter of taking off the stock calipers and rotors, bolting on the aluminum spacer bracket and throwing on the new rotor and stock calipers.

| Installing the Powerslot Plus brakes is a matter of taking off the stock calipers and rotors, bolting on the aluminum spacer bracket and throwing on the new rotor and stock calipers.

Pedal SquishWhat really bothered us in the first place and started us down the road of brake re-engineering is the soft and squishy feel of the stock brakes. Even though the tC uses the same front brakes as the Toyota Celica GT-S, it doesn't share the same great brake feel. We wanted brakes that responded quicker and were more fade resistant.

A sloppy brake feel can be caused by several factors including improper pad selection, boiling brake fluid, caliper deflection, bulging brake lines, firewall flex, and a bit of brake engineering voodoo that we haven't figured out. To diagnose what is causing the problems, however, you must understand the role hydraulics play in the braking system.

When you step on the brake pedal, hydraulic fluid is rammed through a brake master cylinder, which amplifies your foot pressure and forces fluid through brake lines to the calipers. Pressure from the hydraulic fluid forces the calipers to push pad-covered pistons against the rotors. Since the pads are already touching the rotors even when you're off the brakes, when you do step on the brakes, the pistons move very little and the fluid has nowhere to go. Since the pads barely move and the hydraulic fluid is basically uncompressible, pushing against the pistons builds pressure. Like a balloon under pressure, the softest parts begin expanding first. In most cases, it's the rubber portions of the brake lines, followed by the firewall, and then the brake caliper prying itself apart as the pads push against the rotor. It's this expansion that makes the brake pedal feel soft and unresponsive. The harder you step on the pedal, the more these components will expand or bend. Our solution: Stiffen the parts that are expanding and flexing.

| Project Scion tC - 2005 Scion tC

| Project Scion tC - 2005 Scion tC

We already know the stock calipers aren't the main reason for the slop, since the Celica, which uses the same caliper and rotor, doesn't have such a squishy pedal. Besides, there isn't much you can do to strengthen a floating brake caliper other than replace it with a fixed type caliper unit from an expensive big brake conversion kit. Putting an $1,800 set of front brakes on a $16,000 car doesn't make much sense to us, so we're left with changing out the brake lines and picking pads that feel the best.

Squish, as we so scientifically call it, causes extra pedal travel with no additional brake response. The two "flexible" parts in the squish equation we can do something about are the soft, stock rubber brake lines and weak firewall. (Firewall flex is an issue because the brake master cylinder and booster are mounted on it. Every time you step on the brakes, the firewall temporarily and ever so slightly bulges out into the engine bay.)

For now, we'll only replace the stock brake lines with Goodridge stainless-steel-braided lines we sourced from The Tire Rack, since we haven't gotten around to making a master cylinder stopper.

| All we can do about squishy brakes for now is put on Goodrich's stainless steel-braided brake hoses from The Tire Rack.

| All we can do about squishy brakes for now is put on Goodrich's stainless steel-braided brake hoses from The Tire Rack.

One common misconception is that braided lines help in decreasing braking distances. Braided brake lines are just rubber or plastic lines reinforced with a braided stainless-steel and teflon sleeve, which prevents the rubber line inside from expanding under pressure. They don't change the ultimate line pressure in the brake system, so peak braking torque does not change. What does change is the transient brake response, because pedal effort will instantaneously translate to line pressure instead of ballooning the brake lines. It is this quicker response that will take a couple of feet off of high-speed stops. Because these lines are less prone to ballooning, the line pressure, and thus, braking force, is more directly proportional to pedal effort. This is exactly what we felt; Project tC's brakes, although still a bit on the soft side, do respond a lot better.

Pedal FeelBrake pad selection has the biggest effect on pedal feel since pad friction characteristics are directly affected by how much pressure is being applied. Depending on pad material and operating temperatures, braking response and feel can change drastically. Most OE-type pads are a compromise between noise, dust, longevity, and operating temperatures, causing them to have less initial bite and less friction at elevated temperatures. In other words, stock pads are made for soccer moms and commuters, some of whom live in sub-freezing climates.

Other than pad friction, we don't really care about any of these constraints for aggressive street driving. The EBC Greenstuff pads we picked slightly increased pedal firmness under braking and added a lot more initial bite. Although how well a pad first bites isn't an indicator of overall stopping ability, the Powerslot/EBC hardware did offer marginally better stopping distances and much lower rotor temps, which further reduced the soft pedal feel. The only drawback we've noticed from the EBC pads is how abrasive they are to the rotors.

| Performance aside, the addition of larger rotors really takes some of the wimpiness out of the tC. Next time we'll show you how to paint the calipers to match the EBC Greenstuff pads.

| Performance aside, the addition of larger rotors really takes some of the wimpiness out of the tC. Next time we'll show you how to paint the calipers to match the EBC Greenstuff pads.

TestingWe ran a comprehensive brake test on the Powerslot/EBC combination and measured repeated stopping distances and front rotor temperatures for 10 runs. (Look in SCC's March 2006 issue page 82 for our testing procedures.) Although stopping distances didn't improve significantly, the rotor temperatures seem much more tolerant to track-type abuse. If you just want better stops, the EBC pads and Goodridge lines will do the trick. But if you plan to head to the track, a set of Powerslot Plus rotors might save you from a bad case of brake fade and warped rotors. Lesson of the day? Figure out what your car is already equipped with before randomly ordering parts.

We've engineered our way into slightly better brakes that are capable of dissipating a lot more heat. Next time we'll get to the part everyone asks about, TRD's turnkey supercharger kit.

REPEATED {{{80}}}-0 MPH BRAKING DISTANCES (ft) Run Stock Powerslot 1 215.0 213.2 2 216.3 219.8 3 217.4 217.8 4 214.5 219.3 5 210.1 216.8 6 213.1 216.5 7 208.8 212.7 8 209.5 205.7 9 210.2 208.2 10 210.7 205.1 best 80-0 maximum Price* Weight (F) Weight (R) Diameter (F) Diameter (R) stoping distance temp Powerslot Plus $896 18.65 lb. 11.8 lb. 12.8 inches 12.5 inches 205 feet 496 F Stock $N/A 13.65 lb. 8.1 lb. 10.76 inches 10.5 inches 209 feet 648 F * Prices as advertised on tirerack.comPrevious InstallmentsNovember 2005Part I: Improving stick