Real racers all know the value of gearing. It's what comes next when you've reached your power limit, whether regulated or not. The same applies to our NSX project. We don't have the money for a supercharger or turbo kit, nor want to deal the associated headaches. Instead, we're going to change gears-more specifically, the final drive ratio-which will give us better acceleration and torque at street speeds and is a welcome service after 120,000 miles of wear.

|

Project Acura NSX Final Drive Install - When You Can't Make Power, Change Gears

|

Project Acura NSX Final Drive Install - When You Can't Make Power, Change Gears

As always, the plan starts simple: put in a shorter (or numerically bigger) final drive. Unfortunately, the ring and pinion gears required to change the final drive ratio are as far buried in the car as it gets. Getting to it involves yanking the transmission and cracking it open. Since the pinion gear is part of the transmission countershaft, we're going to have to transfer all the gears over to the new shaft. If we're going that far, we might as well freshen up synchros, bearings and seals too, because putting new synchro springs and bearings also requires pulling apart the input and countershaft gear stacks. While we're changing the parts on the countershaft, we might as well freshen up the input shaft. Ah, what the hell, we're in there already-might as well change the oddly non-VTEC friendly spaced USM gears for the JDM/Euro-spec second through fourth gears which use a different input shaft altogether. Now we have new input and countershafts. To save the hassle of yanking the stock pressed fit ring gear off the stock differential, we might as well just replace the diff with an OS Giken unit that already comes with a tighter final drive and all necessary hardware.

With the transmission off, it's also a good time to replace the similarly beat-up OEM twin plate clutch. But because the OEM clutch costs almost as much as a really nice aftermarket piece, we settled for the OS Giken twin place STR clutch kit. Looking at the NSX and all the grime, oil leaks and grease from two exploded CV boots, we decided the prudent man would just drop the entire engine and rear subframe assembly and do the entire job on the ground where we can freshen up all the gaskets and give the entire powertrain a proper anal NSX-owner-style scrub down. After more parts are ordered for all-new engine gaskets and seals, belts, a water pump, thermostat and all new coolant lines, we were finally ready to start.

Now we have a parts list a mile long and almost as expensive as a supercharger kit. But we're happy because we're sticking with the NA plan and the car is still smog friendly. Getting the parts was the easy part. Doing the work is another story all together because dropping an NSX is on the garage floor is something reserved for the craziest or dumbest of mechanics. We had no idea what we were doing and couldn't afford to break any parts, so went to our good friend Mark DiBella of MD Automotive in Westminster, California, got on our knees and begged for his lift, tools and wisdom.

|

Project Acura NSX Final Drive Install - When You Can't Make Power, Change Gears

|

Project Acura NSX Final Drive Install - When You Can't Make Power, Change Gears

OS Super Lock LSD

We won't get into the nitty gritties, but it took a good six-hour day to drop the rear subframe along with the engine and trans. Once that was out, the engine and trans were pulled out from their cradle and separated for the scrub down. In terms of transmissions, the 5-speed transmission is just a burly version of what you would find in an Integra. With the bellhousing off and the transmission case apart, all the guts are exposed but nicely held intact sitting on top of the bellhousing. After running everything through the solvent tank, we started by replacing the stock differential.

When it comes to differentials, OS Giken makes the Cadillac of them all. Well, maybe that's an insult nowadays-call it the Ferrari of performance drivetrain components. The OS Super Lock 1.5-way LSD for the NSX is a clutch type unit with a total of 24 clutch plates (12 on each side). The idea behind having so many plates is to provide enough friction surfaces to have a differential that can truly provide lock up 100 percent under load while being able to slip enough for smooth low-speed operation. Each diff is built with heat-treated internal components, raw-forged gears and precision-machined plates that eliminate the vomit-inducing figure-8 break-in required by most other clutch-type LSDs.

|

Only the speedometer ring gear needed to be transferred from our stock NSX LSD (right) to the OS Super Lock LSD (left). Note the difference between the stock 4.06:1 ring gear compared to the OS 4.44:1 ring gear.

|

Only the speedometer ring gear needed to be transferred from our stock NSX LSD (right) to the OS Super Lock LSD (left). Note the difference between the stock 4.06:1 ring gear compared to the OS 4.44:1 ring gear.

Another patented innovation found only in the OS Super Lock LSD is the small preload springs used in the main pressure ring. This Lock Timing Technology uses these springs to control the release and expansion of the pressure ring in the center of the diff, which in turn controls when and how much the clutch plates engage. OS can custom tune each LSD's clutch engagement timing as well as torque preload. These fine-tuning tricks are what allow the OS Super Lock LSD to provide smoother operation, faster locking, less turn in understeer and even better wet/snow traction.

The engineers at OS determined that the a 1.5-way LSD was the best for FF and MR applications and only offer these off-the-shelf with pre-tuned initial torque and lock progression settings. More or less aggressive units can be special ordered as well as custom set up but factory standard settings are usually best for most users, even in racing.

Gears

Part of the option for our OS Super Lock LSD was their 4.44:1 final drive ratio. The LSD comes with the 4.44 ratio ring gear already mounted, a new countershaft with the matching pinion gear, as well as a new transmission oil pump gear with the same gear teeth that's also driven off the new ring gear. The only hardware that needs to be transferred from the stock NSX LSD is the speedometer ring gear. Even with new bearings, the installation of the new differential is a straightforward drop-in deal. The original differential bearing shims didn't need to be changed on account of OS' super-tight machining tolerances. With the new shorter final drive, we can now keep the engine at reasonably higher speeds for more power even at street speeds. This will give us more acceleration, response and actual torque at the wheel both from the higher drive ratio and the higher-rpm power with the trade-off of more time spent shifting.

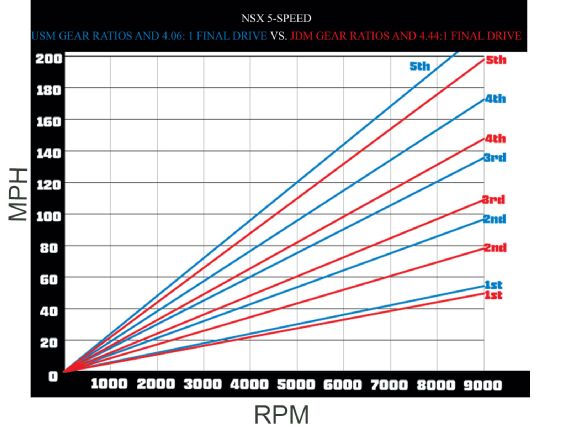

While the transmission was apart and the countershaft replaced (since the pinion gear is part of the countershaft), we opted to also replace the stock USM gears with JDM spec gears which feature a more evenly spaced ratio. Even spacing between the gears allows for the engine rpm to drop right back to just before the stock VTEC engagement point after shifting from the 8000-rpm redline. ScienceofSpeed imports these OEM Japanese gears, which are a direct bolt-on into the U.S.-spec transmission. Some of the gears are directly forged onto the input shaft itself, so the kit comes with a new input shaft and the appropriate second through fourth gears and countershaft gears. Although the gears are different in diameter, the synchros are identical for each gear, so we also ordered new U.S.-spec bearings, brass synchronizer rings, gear selection hubs and sliders as well as new synchro springs for the entire transmission.

|

Project Acura NSX Final Drive Install - When You Can't Make Power, Change Gears

|

Project Acura NSX Final Drive Install - When You Can't Make Power, Change Gears

Clutch

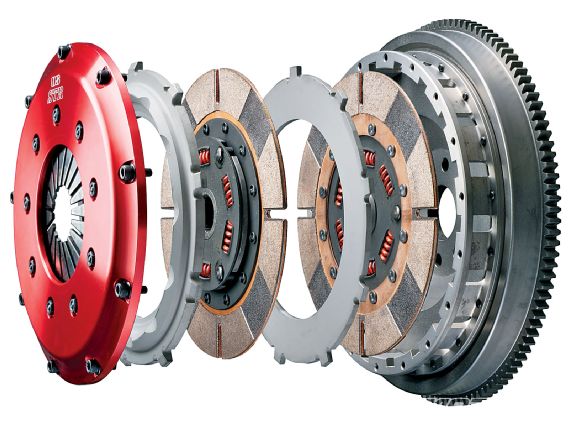

In the case of the NSX, ponying up for a high-quality aftermarket clutch is a good idea because the stock twin plate clutch kit for the 5-speed transmission-which includes flywheel, pressure plate and friction discs-costs more than $1,600. Even if you bought it in separate parts, the pressure plate only comes in the entire kit. Our clutch was fried and looked like it was the original unit when the car was built.

|

OS Giken's STR series racing clutch provides both race-ready performance as well as everyday driving convenience. Each STR series clutch features two sprung metallic discs, an aluminum pressure plate and a lightened chromoly flywheel.

|

OS Giken's STR series racing clutch provides both race-ready performance as well as everyday driving convenience. Each STR series clutch features two sprung metallic discs, an aluminum pressure plate and a lightened chromoly flywheel.

We also went to OS Giken for its twin plate metallic disk STR clutch kit. The hardware is a direct bolt-on for the 5-speed transmission and reduces the overall rotating mass by about 10 lbs. Furthermore, the Giken STR clutch kit includes a new clutch slave cylinder and throw out fork to change the stock pull-type configuration to a push-type clutch, which is easier to service and less prone to wear. The clutch is rated for a higher clamping force, which isn't really necessary in our case but does engage much faster and have a metallic rattle when the clutch pedal is engaged due to the friction plates moving about.

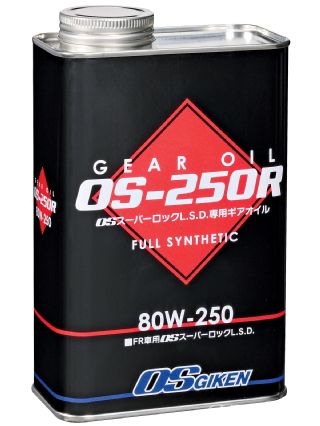

With much help from Mark at MD Automotive, we managed to reassemble the transmission to the engine, drop it back into the rear subframe and finally drop the car back onto it. Once again, much easier said than done. The next debacle was over what gear oil to run since both the differential and the gears share the same oil. Honda's MT transmission oil is essentially 10W30 motor oil and is extremely thin for gear oil, which means Honda transmissions are built to relatively tighter clearances. OS suggests its own specially formulated full synthetic OS-250R differential oil for the Super Lock LSD. This would give the exact amount of friction in the differential for the locking plates to operate optimally. Unfortunately, it only comes in a very heavy 80W250 weight, which might cause havoc on our pristine new synchros. We finally settled on breaking in the new transmission and seating all the gears and synchros with standard Honda manual transmission fluid for the first couple hundred miles. Hopefully, all the gears would be happy by then and we would switch over and see if the transmission liked the OS gear oil.

While the Super Lock LSD worked reasonably well with the Honda MTF, there was a bit of clunking and popping from the diff during tight maneuvers due to the low weight gear oil. Even so, the Super Lock LSD is much more quiet than any other clutch-type LSD we've ever used. We didn't bother with the typical tight figure-8 break in, but did manage to beat on the diff a little prior to changing fluids. We saw little to no debris when it was drained, which was a good sign that everything was put together right. Although we had reservations about putting the heavy weight OS gear oil into our very expensively rebuilt transmission, we did want to try it for the sake of the LSD. As it turned out, the heavy Synthetic OS gear oil was just as smooth to shift under summer conditions and got rid of much of the excess popping from the diff. To really test the new gears out, we headed off to California Speedway to repeat our quarter-mile and figure-8 tests to see what we gained.

|

Project Acura NSX Final Drive Install - When You Can't Make Power, Change Gears

|

Project Acura NSX Final Drive Install - When You Can't Make Power, Change Gears

Testing

Even before getting to the track, one thing is apparent: The new 4.44:1 final drive does wonders for the 5-speed NSX. The shorter final now makes the NSX feel more like driving a zippy, high-strung S2000 that likes to stay at higher engine speeds. Taking off from a stop, the lethargic feel of waiting for VTEC to kick in at 6000 rpm is nearly gone and the gear spacing us now perfect without the gaping hole between first and second gear. The engine also revs much faster due in part to the better power band and lighter flywheel. Clutch engagement is strong, but not so immediate so as to make the car undriveable. Compared to many other multi-plate clutch systems, the OS STR clutch much easier to use in traffic and requires just a slight bit more pedal effort than the stock hardware.

|

Even with a tighter-than-NSX-R final drive ratio, the OS final drive is very usable for daily driving and lets the engine hang around 3700 rpm while cruising at 80 mph compared to about 3500 rpm with the stock gears.

|

Even with a tighter-than-NSX-R final drive ratio, the OS final drive is very usable for daily driving and lets the engine hang around 3700 rpm while cruising at 80 mph compared to about 3500 rpm with the stock gears.

At the quarter-mile, we picked off a tenth from our time even though the trap speed was a little slower. The quarter-mile with the new gears and final also required a shift from third to fourth gear to complete the pass whereas the OEM gear set could finish the pass in third gear, meaning some time was lost in the additional shift. More importantly, we took off three-tenths of a second from our 0-60 times on account of the tighter final drive.

We lost some time on the figure-8. The car was far easier to drive, but because of the dimensions of the figure-8, our new gear set would bang the engine against the rev limiter a bit before the braking point for the turn in. The distance was small enough that upshifting for a split second and then downshifting for the turn would have lost more time, so we had to sit on the limiter for a short time unlike before. This cost us some top speed and thus time, but if the dimensions were just a little bit different, we're sure the new gear seat would have performed better.

In the turns, the car generated the same average 1.0 g lateral acceleration because we're on the same Yokohama Advan Neova AD07 tires, but the feel was definitely different. The higher revs through the turn and better LSD mean the car was much easier to drive and control as it oversteered at the corner exit. The transition between understeer and oversteer was much easier to balance due to the smooth but responsive transition between lock under power and release as the gas was feathered.

Lap times aside, the OS Giken hardware along with JDM gear set is probably the most noticeable and practical improvement we've made to an already great car. If you want to retain the stock Honda reliability and trackability while keeping your car streetable, this drivetrain upgrade is probably the best investment you can make.

Stock Gearing OS Giken & JDM gearing Quarter-mile e.t. (sec.) 13.7 13.6 Trap speed (mph) 103.5 101.4 0-60 mph (sec.) 5.7 5.4 Figure-8 best lap time (sec.) 24.926 25.035 Average lateral acceleration (g) 1.0 1.0