Letters To The Editor - Paper Cuts - December 2008

Hey Max,

I have two questions, I understand the concept of using gusset plates and braces to strengthen a frame, but why a diamond shape; does it help keep the frame from possibly breaking or cracking? Also, based on the cost, strength, time, and personal preference, which kind of body-drop would be best suited to do on an S-10 (square Dime) stock-floor (by building a new frame), traditional, or channeling? Thanks for your answers, I look forward to reading "Paper Cuts" every month.

C. Bickford

Pikeville, Tennessee

| letters To The Editor December 2008 example

C.,

To answer the diamond question, we are going to have to touch on the mechanical properties of metal. Let's take a piece of uncooked spaghetti. If you were to hold the spaghetti at its ends, then bend it around, you will notice that you can bend it pretty far before it breaks. But, if you were to hold that same piece of spaghetti with your fingers only an inch apart, it will not bend much at all before it breaks. The reason that it breaks so easily, even though the same amount of force is applied, is because by moving the bending loads so much closer to one another and concentrating the stress to one point, you have created a stress riser.

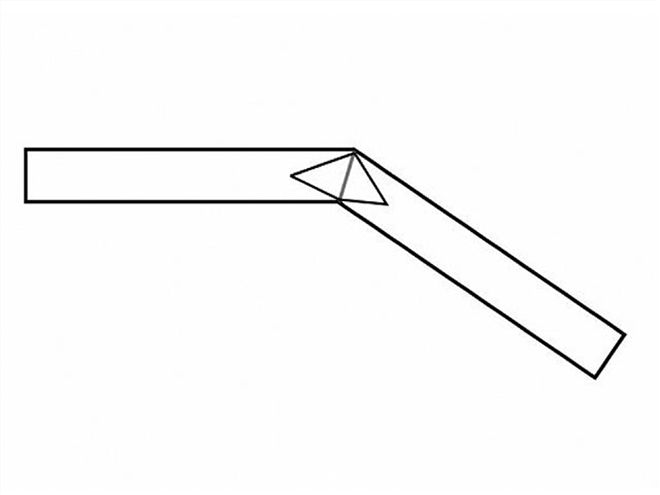

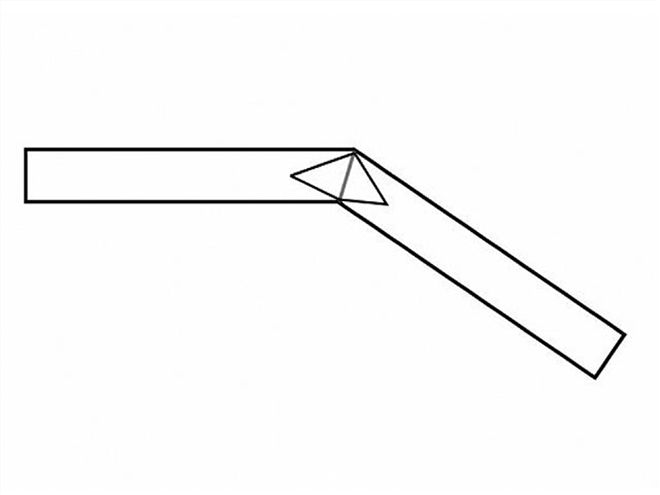

Now, if you cut a piece of 2x3 and miter it to make an angle, that seam is, by its very nature, a stress riser. So, if our little demonstration with the spaghetti noodle showed us anything, it is that if you can spread the stress out, the part will live longer and handle more stress. So, how do you spread the stress out without creating another stress riser? In a situation like the welded 2x3 seam, a diamond-shaped plate properly placed over the welded seam will spread the stress without adding too much unnecessary weight.

What the diamond does to draw stress away from the seam is to run the stress along the length of the tube, and terminate it in the middle of the tube, which is a really hard place for a crack to propagate from. In the drawing, notice that the diamond is not shaped like you would think. The points are at the ends of the welded seam and at the center of each tube. You can even round the points of the diamond to relieve even more stress, but it's not necessary on an already overbuilt minitruck. I would like to point out, though, that a diamond thicker than 1/8-inch is unnecessary on any street-driven vehicle.

As for my opinion on a stock-floor body drop or a traditional body-drop, it is totally situational. Some vehicles lend themselves to one way or the other, sometimes either way will work just fine. On an S-10, we have always body-dropped them traditional, but I have done both ways on a Tacoma, and prefer a traditional. I can't say which way I would suggest a beginner to go, because there are too many pros and cons for either one. I think that the deal breaker would be: based on who is helping, which technique do they have more experience using, or which tech article do you have?

Max,

I own an '03 Chevy extended cab S-10, and as I'm sure you know, there is a ton of plastic in these trucks. Panels, doors, dash bezel, A/C vents, and so on. What materials do I need in order to smooth and maybe prime my panels for my local body shop to color-match it to my truck? I've had people tell me I need a good adhesion promoter and flexing agent to help with the sticking of the paint, and to keep the paint from chipping and/or cracking. Any advice would be great.

Andy

Via the Internet

Andy,

This is a good question, with more than one answer. I can tell you what we've done in the past when addressing painted plastic trim pieces, but some people might argue with our procedure. First off, be sure that the parts are as oil-free as possible, as dashes tend to get oils smeared all over them throughout their lives, so this is an important step. For this, you can use denatured alcohol or a wax and grease remover.

Once the dash is good and clean, use some 36-grit sandpaper, scuff up the surface real good, and be extra sure to get everything that is going to be painted. At this point, you can do any modifications to the dash that you want.

Once the bodywork is finished, primer the dash with a good epoxy primer (this is where someone else might disagree). Then, prep the primer for paint, just as you normally would.

We have had good luck prepping the parts this way, but there may be a better way that I am not aware of.

Thank you all for stopping by "Paper Cuts" this month. Be sure to stay tuned for next month's exclusive interview with some of the industry's heros about a disease that is afflicting our automotive brethren.

To submit a question, e-mail:mini.truckin@sourceinterlink.com

| letters To The Editor December 2008 example

C.,

| letters To The Editor December 2008 example

C.,