To submit a question, e-mail:mini.truckin@sourceinterlink.com

Hey Mini Truckin',

I've been reading your mag for a few years now (10 I think), and I have noticed that the suspensions seem to be getting bigger and bigger every year. I'm not talking about bigger 'bags or more travel, it's the material being used. 2-inch x .250 wall tubing, 1-inch heim joints, and 1/4-inch gussets on everything. What gives? Oh yeah, I love the mag, keep up the good work.

Fax Mish of Kio Bustumz

P.S. That Max guy is oh-so-sexy

Hey Fax,

Thanks for the compliments, it's nice to hear someone out there appreciates a ruggedly handsome man, such as myself. Anyway, onto the question at hand, I too have noticed that the materials being used lately are of monstrous proportions and I'm not sure what has caused it.

I assume the off-road industry is inspiring the minitruck industry and builders are using what they have become accustomed to seeing on those trucks. As a whole, I'm glad to see that minis are being built far nicer than they ever have, but the trophy-truck sized link systems are a bit overboard. I have a friend with a 250k PreRunner that is very capable and only using 7/8-inch heims on the upper bars with no issues.

So, what is the right size material to use on a specific job? Honestly, a definitive answer does not exist. But what I can tell you are the load limits of commonly used products and you can make your own decision based on your particular needs.

The first thing we need to do is define what inch-strong-inch is. Metal is not simply defined as strong, but instead with strength in specific areas. Below is a list of the standard inchloads-inch that a part will be placed in.

| maximized Easy Questions With Hard Answers tension Arrows

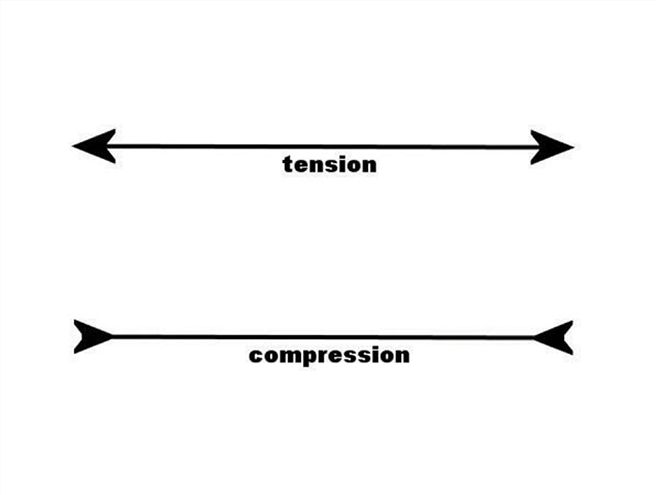

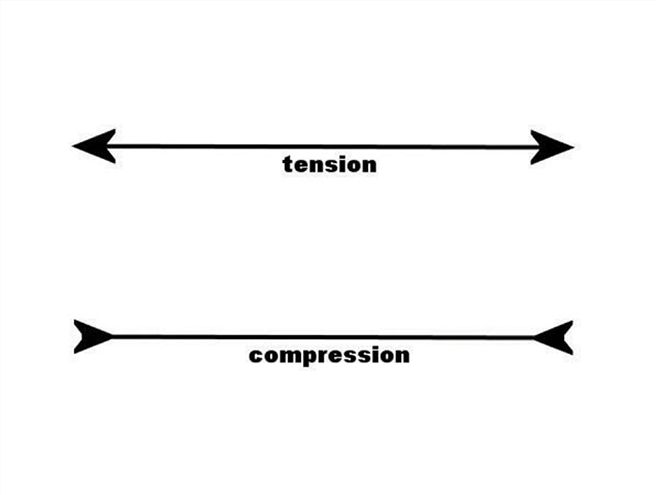

Tension is when a part is being pulled on from each end. Take for instance rope, it is only strong in tension, it could under no circumstance be used in any other way. This is most commonly referred to as the tensile strength.

Compression is the exact opposite of tension, though strangely, some materials will handle more compression than another material that has a higher tensile strength. Take for example 1020 mild steel, in longer lengths has a higher compression value than 4130, which has a roughly 15-percent higher tensile strength.

| maximized Easy Questions With Hard Answers bending Load

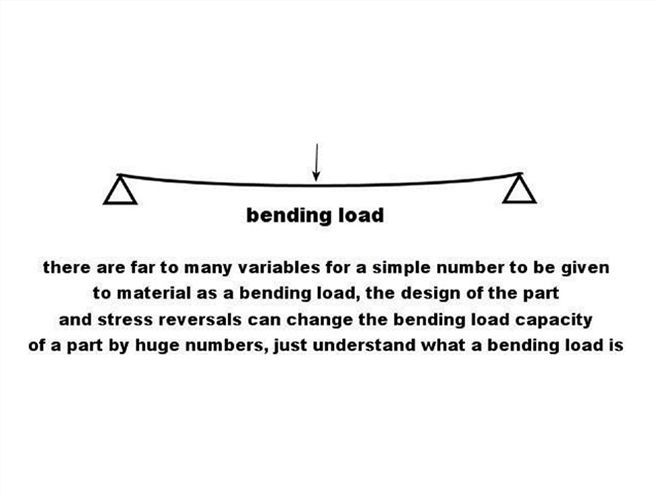

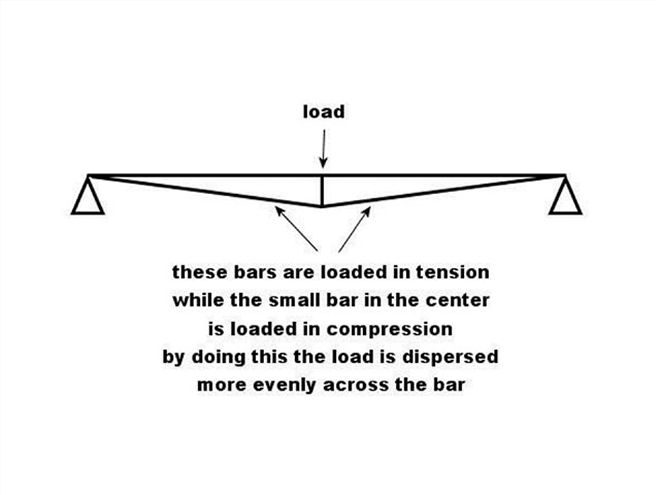

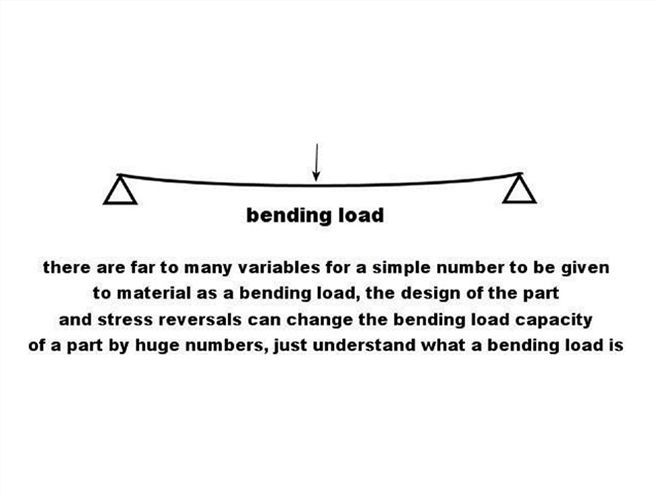

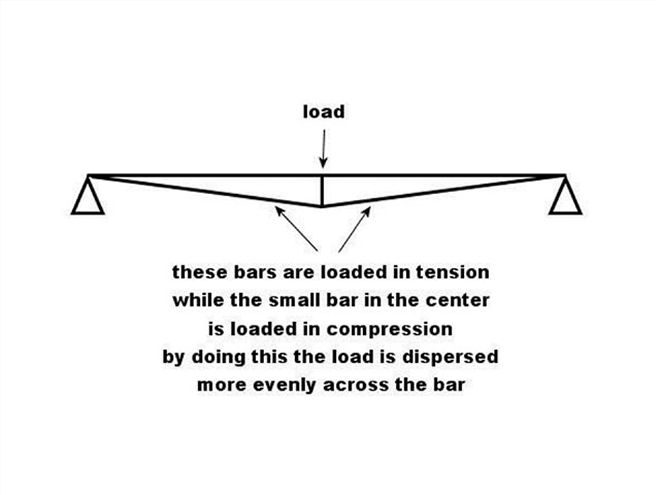

Bending load is just how is sounds. A part that has a concentrated point of stress (a 'bag on a lower bar for example) should have reinforcement added to spread the concentrated stress across the part.

| maximized Easy Questions With Hard Answers shears

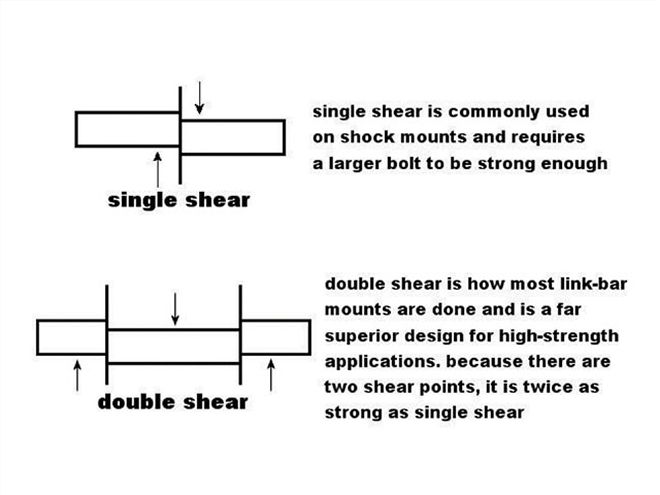

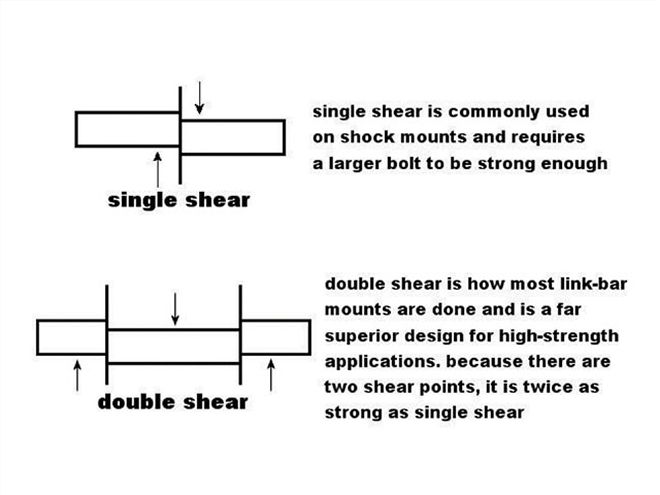

Shear loads are applied in a manner that is literally trying to cut the material in half (think scissors) and is most often used in highly stressed areas. As a rule of thumb, shear loads are considered to be 60 percent of the material's tensile strength. For example, if a part has a tensile strength of 10,000 pounds, then the shear strength of the material would be 6,000 pounds.

| maximized Easy Questions With Hard Answers load Example

Axial load refers to a heim joint and is the load applied along the bearing bore axis (where the bolt goes through) commonly seen when using the spherical part as a ball joint.

What size material should you use for a particular application? I can't tell you, it is too hard to say specifically what size material/part to use. After a quick call to my buddy, Jack at hm-engineering.com, we netted some spherical bearing (heim joint) information, and the rest of the info was found out on the webbernet. Let's take a look at some commonly used parts and material.

In pounds… Tensile strength Shear Grade 8-1/2-inch bolt 21,000 12,{{{600}}} Grade 2-1/2-inch bolt 10,500 6,{{{300}}} High grade 3/4-inch heim 28,000 not recommended for axial use Low grade 3/4-inch heim 14,300 not recommended for axial use High grade 3/8-inch heim 9,550 not recommended for axial use 1-inch uni-ball 104,000 19,300 (axial) 7/8-inch uni-ball 67,000 10,800 (axial) 3/4-inch uni-ball 53,000 8,000 (axial) 1-1/2-inch x .250 DOM 78,560 1-1/2-inch x .250 4130 88,380 1-1/2-inch x .120 DOM 42,{{{960}}} 1-inch x .120-inch DOM 27,{{{200}}} I know... What about the right size material to use on my frame? The best I can say is to look at what the vehicle came with stock and think similar. If the frame was 2x5-inches x.120-inch C-channel, then it is reasonable to think that you could get away with 2x3-inch x.120-inch boxed tubing. The frame flexed from the factory, you can expect it to flex once you modify it. Trying to eliminate any frame flexing is impossible without a roll cage, just do your homework and keep stress risers to a minimum.

Overbuilding is safe, but where do you draw the line? A solid frame, 2-inch heim joints, a rearend from a trash truck?

-Max Fish

| maximized Easy Questions With Hard Answers tension Arrows

Tension is when a part is being pulled on from each end. Take for instance rope, it is only strong in tension, it could under no circumstance be used in any other way. This is most commonly referred to as the tensile strength.

Compression is the exact opposite of tension, though strangely, some materials will handle more compression than another material that has a higher tensile strength. Take for example 1020 mild steel, in longer lengths has a higher compression value than 4130, which has a roughly 15-percent higher tensile strength.

| maximized Easy Questions With Hard Answers tension Arrows

Tension is when a part is being pulled on from each end. Take for instance rope, it is only strong in tension, it could under no circumstance be used in any other way. This is most commonly referred to as the tensile strength.

Compression is the exact opposite of tension, though strangely, some materials will handle more compression than another material that has a higher tensile strength. Take for example 1020 mild steel, in longer lengths has a higher compression value than 4130, which has a roughly 15-percent higher tensile strength.

| maximized Easy Questions With Hard Answers bending Load

Bending load is just how is sounds. A part that has a concentrated point of stress (a 'bag on a lower bar for example) should have reinforcement added to spread the concentrated stress across the part.

| maximized Easy Questions With Hard Answers bending Load

Bending load is just how is sounds. A part that has a concentrated point of stress (a 'bag on a lower bar for example) should have reinforcement added to spread the concentrated stress across the part.

| maximized Easy Questions With Hard Answers shears

Shear loads are applied in a manner that is literally trying to cut the material in half (think scissors) and is most often used in highly stressed areas. As a rule of thumb, shear loads are considered to be 60 percent of the material's tensile strength. For example, if a part has a tensile strength of 10,000 pounds, then the shear strength of the material would be 6,000 pounds.

| maximized Easy Questions With Hard Answers shears

Shear loads are applied in a manner that is literally trying to cut the material in half (think scissors) and is most often used in highly stressed areas. As a rule of thumb, shear loads are considered to be 60 percent of the material's tensile strength. For example, if a part has a tensile strength of 10,000 pounds, then the shear strength of the material would be 6,000 pounds.

| maximized Easy Questions With Hard Answers load Example

Axial load refers to a heim joint and is the load applied along the bearing bore axis (where the bolt goes through) commonly seen when using the spherical part as a ball joint.

What size material should you use for a particular application? I can't tell you, it is too hard to say specifically what size material/part to use. After a quick call to my buddy, Jack at hm-engineering.com, we netted some spherical bearing (heim joint) information, and the rest of the info was found out on the webbernet. Let's take a look at some commonly used parts and material.

In pounds… Tensile strength Shear Grade 8-1/2-inch bolt 21,000 12,{{{600}}} Grade 2-1/2-inch bolt 10,500 6,{{{300}}} High grade 3/4-inch heim 28,000 not recommended for axial use Low grade 3/4-inch heim 14,300 not recommended for axial use High grade 3/8-inch heim 9,550 not recommended for axial use 1-inch uni-ball 104,000 19,300 (axial) 7/8-inch uni-ball 67,000 10,800 (axial) 3/4-inch uni-ball 53,000 8,000 (axial) 1-1/2-inch x .250 DOM 78,560 1-1/2-inch x .250 4130 88,380 1-1/2-inch x .120 DOM 42,{{{960}}} 1-inch x .120-inch DOM 27,{{{200}}} I know... What about the right size material to use on my frame? The best I can say is to look at what the vehicle came with stock and think similar. If the frame was 2x5-inches x.120-inch C-channel, then it is reasonable to think that you could get away with 2x3-inch x.120-inch boxed tubing. The frame flexed from the factory, you can expect it to flex once you modify it. Trying to eliminate any frame flexing is impossible without a roll cage, just do your homework and keep stress risers to a minimum.

Overbuilding is safe, but where do you draw the line? A solid frame, 2-inch heim joints, a rearend from a trash truck?

| maximized Easy Questions With Hard Answers load Example

Axial load refers to a heim joint and is the load applied along the bearing bore axis (where the bolt goes through) commonly seen when using the spherical part as a ball joint.

What size material should you use for a particular application? I can't tell you, it is too hard to say specifically what size material/part to use. After a quick call to my buddy, Jack at hm-engineering.com, we netted some spherical bearing (heim joint) information, and the rest of the info was found out on the webbernet. Let's take a look at some commonly used parts and material.

In pounds… Tensile strength Shear Grade 8-1/2-inch bolt 21,000 12,{{{600}}} Grade 2-1/2-inch bolt 10,500 6,{{{300}}} High grade 3/4-inch heim 28,000 not recommended for axial use Low grade 3/4-inch heim 14,300 not recommended for axial use High grade 3/8-inch heim 9,550 not recommended for axial use 1-inch uni-ball 104,000 19,300 (axial) 7/8-inch uni-ball 67,000 10,800 (axial) 3/4-inch uni-ball 53,000 8,000 (axial) 1-1/2-inch x .250 DOM 78,560 1-1/2-inch x .250 4130 88,380 1-1/2-inch x .120 DOM 42,{{{960}}} 1-inch x .120-inch DOM 27,{{{200}}} I know... What about the right size material to use on my frame? The best I can say is to look at what the vehicle came with stock and think similar. If the frame was 2x5-inches x.120-inch C-channel, then it is reasonable to think that you could get away with 2x3-inch x.120-inch boxed tubing. The frame flexed from the factory, you can expect it to flex once you modify it. Trying to eliminate any frame flexing is impossible without a roll cage, just do your homework and keep stress risers to a minimum.

Overbuilding is safe, but where do you draw the line? A solid frame, 2-inch heim joints, a rearend from a trash truck?