| 1967 Chevrolet C10 front Passenger Side View

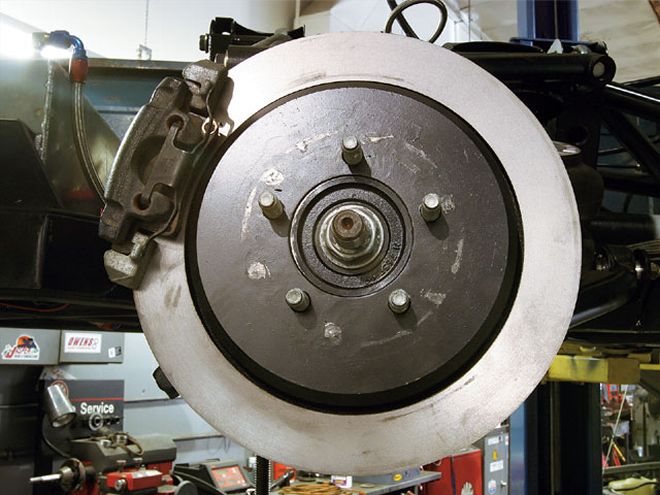

Back in the Apr. '07 issue, we chronicled the buildup of a completely new chassis for our '67 Chevy C10 sport truck by Orange County Auto Shop. The goal was to build a chassis that would lower the body closer to the ground without having to cut up the floor of the cab with a traditional body drop. To accomplish this goal, we built the chassis out of 2x4x0.120-inch rectangular steel tubing that was approximately 2 inches shorter in height than the stock chassis, which made lowering the body downward very easy. We also swapped out the stock 12-bolt solid rear axle, in favor of an independent rear suspension that featured a differential taken from an '03 Ford Expedition. The IRS kept the driveline from moving up and down with the movement of the suspension, and that also enabled us to further lower the body down on the chassis without having to modify the transmission tunnel within the cab. The chassis worked out beautifully, and now we are ready to finish up the front and rear suspensions.

| 1967 Chevrolet C10 front Passenger Side View

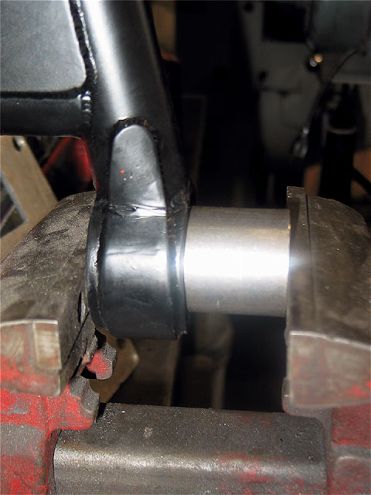

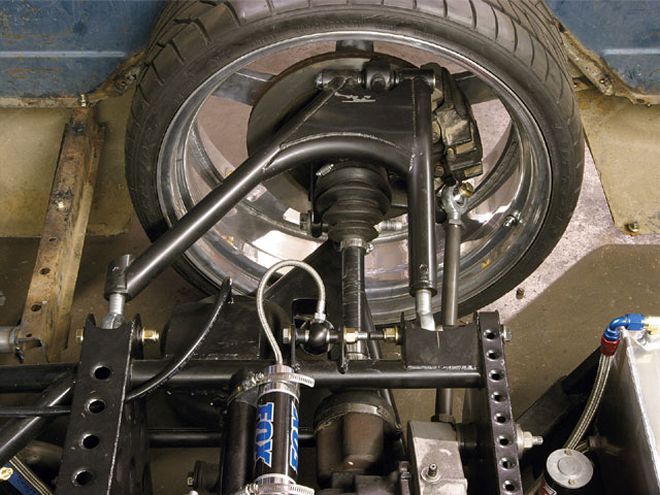

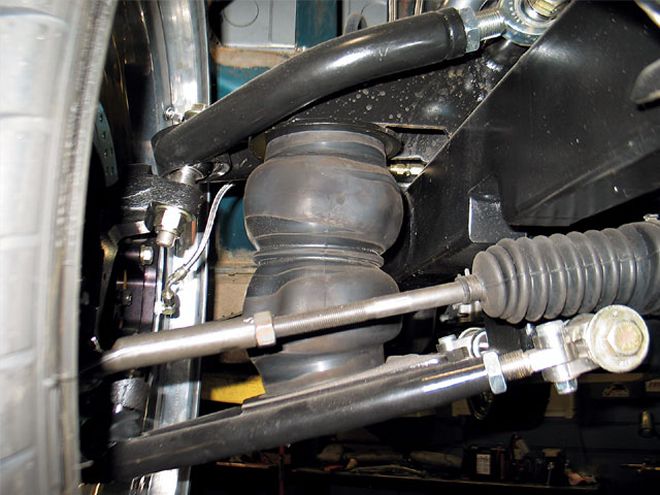

Our control arms, like all of the bulkheads and crossmembers in our chassis, were built from 4130 chrome-moly tubing. All of our pivot points in the suspension swing on FK Bearings 1-inch spherical bearings and 3/4-inch rod ends. These bearings feature a Teflon liner to wipe the bearing clean as it rotates, and the entire assembly is much stronger than a standard bushing. We chose Slam Specialties airbags to actuate the suspension and provide ride height adjustment for a couple of good reasons. For one, they are reliable and have a great track record of not failing. Secondly, these airbags offer extremely good travel without the 'bag's outer diameter expanding greatly as air pressure increases. This means that the 'bags will fit well into tight spaces, which is what we are faced with when trying to package the 'bags, shocks, and rear axles all within the confines of the rear control arms. To control the movement of the suspension and keep the ride in check, we went with Fox Shox 2.0 reservoir dampers. These shocks are also fully rebuildable, and we'll be able to re-valve them, should the ride quality need improvement once the truck hits the road.

| 1967 Chevrolet C10 front Passenger Side View

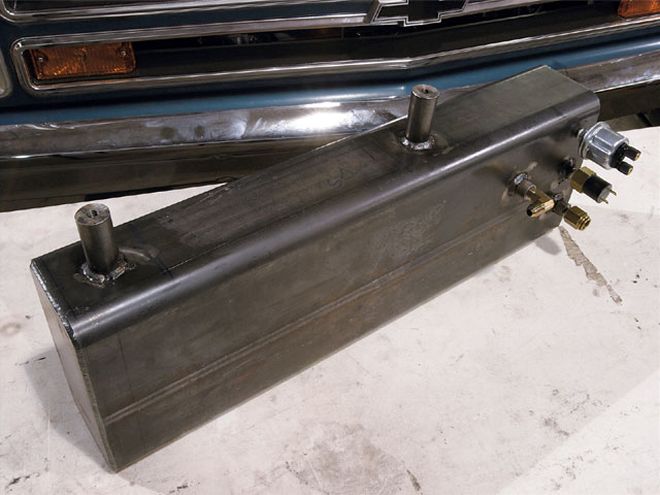

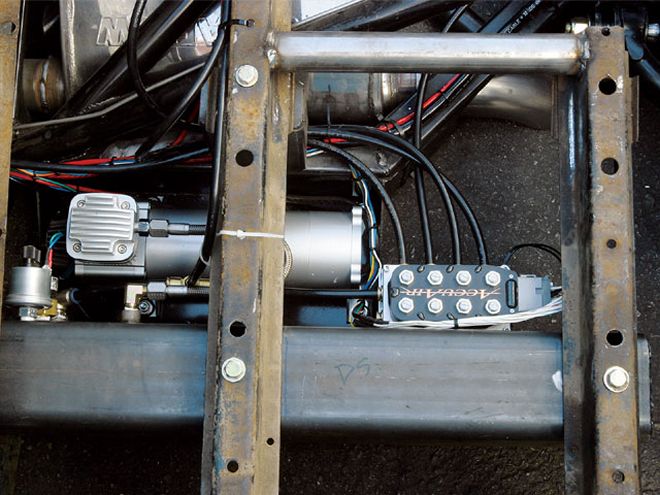

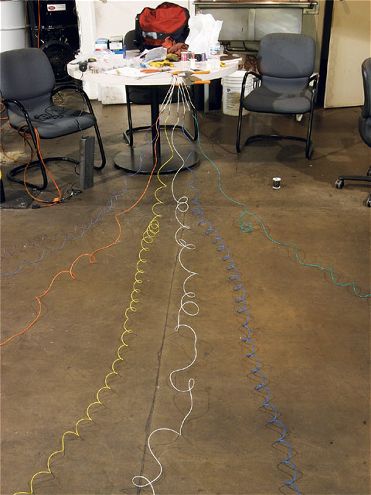

Our air source for the suspension comes from a pair of Air Zenith OB1 100-percent duty cycle compressors. These 12-volt air compressors offer quick fill times, are fully rebuildable, and have an oilless design, which means that maintenance is minimal. The compressors will fill two 3.3-gallon reserve air storage tanks, which we built ourselves. To control the flow of air between the storage tanks and the airbags, we chose AccuAir's VU4 electric valve and manifold combo. This very small system features eight individual valves built into a 5x3-inch aluminum manifold that will independently control airflow to all four corners of the suspension. Not only is the unit small, but it features 3/8-inch ports, so the air will flow fast and the suspension will move quickly, and it also comes with a pre-wired connector to adapt to any switchbox you like. Those are the basic parts we'll be installing in this story. Let's take a look at how it all came together.

The Final WordSo, that's how the suspension of our '67 was made. It was all done in a massive effort to lay this truck flat on the ground and keep the floor of the cab looking like this. Look at all that legroom! Stay tuned for the next installment of this series, because we'll be showing you how we stuffed an all-aluminum Chevy LS2 into this truck and made it run with a carburetor and electronic Overdrive transmission.

| 1967 Chevrolet C10 front Passenger Side View

Back in the Apr. '07 issue, we chronicled the buildup of a completely new chassis for our '67 Chevy C10 sport truck by Orange County Auto Shop. The goal was to build a chassis that would lower the body closer to the ground without having to cut up the floor of the cab with a traditional body drop. To accomplish this goal, we built the chassis out of 2x4x0.120-inch rectangular steel tubing that was approximately 2 inches shorter in height than the stock chassis, which made lowering the body downward very easy. We also swapped out the stock 12-bolt solid rear axle, in favor of an independent rear suspension that featured a differential taken from an '03 Ford Expedition. The IRS kept the driveline from moving up and down with the movement of the suspension, and that also enabled us to further lower the body down on the chassis without having to modify the transmission tunnel within the cab. The chassis worked out beautifully, and now we are ready to finish up the front and rear suspensions.

| 1967 Chevrolet C10 front Passenger Side View

Back in the Apr. '07 issue, we chronicled the buildup of a completely new chassis for our '67 Chevy C10 sport truck by Orange County Auto Shop. The goal was to build a chassis that would lower the body closer to the ground without having to cut up the floor of the cab with a traditional body drop. To accomplish this goal, we built the chassis out of 2x4x0.120-inch rectangular steel tubing that was approximately 2 inches shorter in height than the stock chassis, which made lowering the body downward very easy. We also swapped out the stock 12-bolt solid rear axle, in favor of an independent rear suspension that featured a differential taken from an '03 Ford Expedition. The IRS kept the driveline from moving up and down with the movement of the suspension, and that also enabled us to further lower the body down on the chassis without having to modify the transmission tunnel within the cab. The chassis worked out beautifully, and now we are ready to finish up the front and rear suspensions.

| 1967 Chevrolet C10 front Passenger Side View

Our control arms, like all of the bulkheads and crossmembers in our chassis, were built from 4130 chrome-moly tubing. All of our pivot points in the suspension swing on FK Bearings 1-inch spherical bearings and 3/4-inch rod ends. These bearings feature a Teflon liner to wipe the bearing clean as it rotates, and the entire assembly is much stronger than a standard bushing. We chose Slam Specialties airbags to actuate the suspension and provide ride height adjustment for a couple of good reasons. For one, they are reliable and have a great track record of not failing. Secondly, these airbags offer extremely good travel without the 'bag's outer diameter expanding greatly as air pressure increases. This means that the 'bags will fit well into tight spaces, which is what we are faced with when trying to package the 'bags, shocks, and rear axles all within the confines of the rear control arms. To control the movement of the suspension and keep the ride in check, we went with Fox Shox 2.0 reservoir dampers. These shocks are also fully rebuildable, and we'll be able to re-valve them, should the ride quality need improvement once the truck hits the road.

| 1967 Chevrolet C10 front Passenger Side View

Our control arms, like all of the bulkheads and crossmembers in our chassis, were built from 4130 chrome-moly tubing. All of our pivot points in the suspension swing on FK Bearings 1-inch spherical bearings and 3/4-inch rod ends. These bearings feature a Teflon liner to wipe the bearing clean as it rotates, and the entire assembly is much stronger than a standard bushing. We chose Slam Specialties airbags to actuate the suspension and provide ride height adjustment for a couple of good reasons. For one, they are reliable and have a great track record of not failing. Secondly, these airbags offer extremely good travel without the 'bag's outer diameter expanding greatly as air pressure increases. This means that the 'bags will fit well into tight spaces, which is what we are faced with when trying to package the 'bags, shocks, and rear axles all within the confines of the rear control arms. To control the movement of the suspension and keep the ride in check, we went with Fox Shox 2.0 reservoir dampers. These shocks are also fully rebuildable, and we'll be able to re-valve them, should the ride quality need improvement once the truck hits the road.

| 1967 Chevrolet C10 front Passenger Side View

Our air source for the suspension comes from a pair of Air Zenith OB1 100-percent duty cycle compressors. These 12-volt air compressors offer quick fill times, are fully rebuildable, and have an oilless design, which means that maintenance is minimal. The compressors will fill two 3.3-gallon reserve air storage tanks, which we built ourselves. To control the flow of air between the storage tanks and the airbags, we chose AccuAir's VU4 electric valve and manifold combo. This very small system features eight individual valves built into a 5x3-inch aluminum manifold that will independently control airflow to all four corners of the suspension. Not only is the unit small, but it features 3/8-inch ports, so the air will flow fast and the suspension will move quickly, and it also comes with a pre-wired connector to adapt to any switchbox you like. Those are the basic parts we'll be installing in this story. Let's take a look at how it all came together.

| 1967 Chevrolet C10 front Passenger Side View

Our air source for the suspension comes from a pair of Air Zenith OB1 100-percent duty cycle compressors. These 12-volt air compressors offer quick fill times, are fully rebuildable, and have an oilless design, which means that maintenance is minimal. The compressors will fill two 3.3-gallon reserve air storage tanks, which we built ourselves. To control the flow of air between the storage tanks and the airbags, we chose AccuAir's VU4 electric valve and manifold combo. This very small system features eight individual valves built into a 5x3-inch aluminum manifold that will independently control airflow to all four corners of the suspension. Not only is the unit small, but it features 3/8-inch ports, so the air will flow fast and the suspension will move quickly, and it also comes with a pre-wired connector to adapt to any switchbox you like. Those are the basic parts we'll be installing in this story. Let's take a look at how it all came together.