| airbag And Hydraulics Buyers Guide custom Truck Bed

There have been a lot of long-standing head-to-head competitions over time: Coke versus Pepsi, McDonald's versus Burger King, and hydraulics versus airbags. When it comes to adjustable suspensions, the debate never seems to end. Which method of lifting and lowering your truck is the best, and how do you know?

The thing is, comparing hydraulics with airbags is a little like comparing apples with oranges. Each method has its advantages, and its disadvantages, but they are significantly in their function. Because of that, we're here to help you make an educated decision in which method of adjustable suspension is best suited for you. We'll explain the advantages and disadvantages of each method. We're here to clear up the gunk.

A few things that you should know before doing either method: 1. Don't do this unless you're willing to get dirty.Adjustable suspensions, be it airbags or hydraulics, require some form of maintenance. From the simple things such as cleaning out your valves, to the more complicated rebuilding of a cylinder, an adjustable suspension needs work occasionally. Most of the work is generally no more complicated than changing your oil, but you'd better know what a wrench looks like, or you're in trouble.

2. How much work are you willing to do or pay for?Every install is different for every truck, so keep that in mind. You may cruise your S-10 into the local shop and ask them to lay it on the frame on 17s. On the other hand, you could ask them to body-drop your truck on 22s and make sure it clears the tires to turn. Whichever method you use to lift your truck off its pavement-scraping stance can affect how easy or how hard it's going to be to clear those tires.

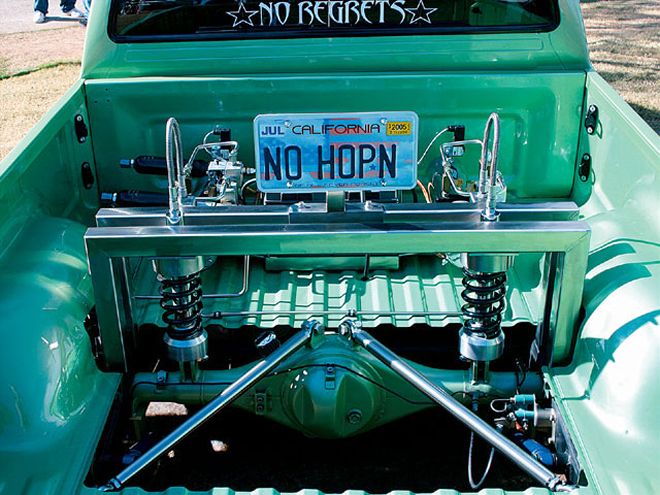

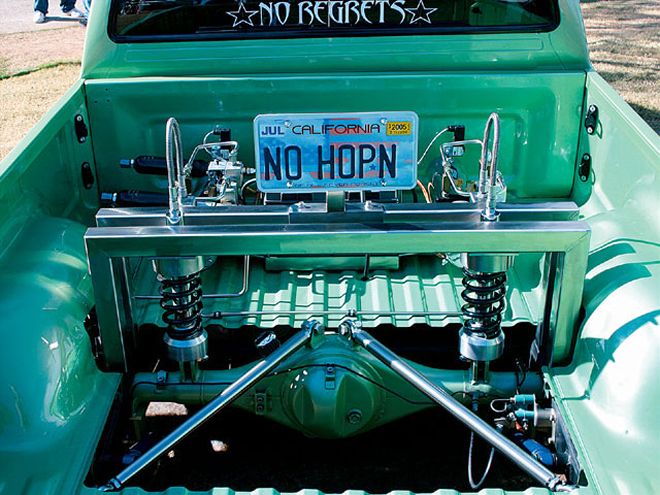

How It Works: Hydraulics Hydraulics get a bad rap. Plain and simple, a lot of people have a misconception about hydraulics and their place in the custom-truck industry. Hydraulic adjustable suspension systems, also known as juice or lifts, are the original adjustable suspension. Back in the '60s, early lowriders adapted pumps from the landing gear of planes to their rides so they could lift them up and down. The problems came in the form of leaks, broken pumps, and poor installations. A lot of people associate hydraulics with messy oil spills, hopping cars, and tons of batteries, but we're here to explain what you can really do with juice.

The premise is simple enough: Use a hydraulic pump to extend a cylinder, and use that to lift your ride. That's the easy part, so let's dig a little deeper.

A hydraulic pump is made up of a few different parts. The pump assembly is anchored to a block. Attached to one end of the block is a motor, and at the other end is a tank. Inside of the tank, attached to the block, is a pump head. When the motor is given power, it turns the pump head, which pushes the fluid out to the cylinders. The fluid is controlled by valves, called dumps, which direct the pressurized fluid into the cylinders to extend and lift your truck. When you want to drop the truck, you open the dumps, causing pressure to release and push the fluid through to a needle valve called a slow-down valve, and through the slow-down you can adjust how fast your truck drops.

The pump has to get power somehow, though, and that's where batteries come into play. You can use any number of batteries, and the more you use, the faster your truck lifts. Each battery is wired in series, so the voltage on the last battery in the series is what ends up going to the pump. To switch the power from the batteries to the pump, a solenoid is used. A solenoid is basically a heavy-duty relay that you activate by hitting a switch. When the circuit is activated, the solenoid opens and power is given to the pump.

Your basic hydraulic setup requires the following: pump(s), dump(s), fittings, hydraulic hoses, cylinders, switches, batteries and solenoids. For more information, check out www.prohopper.com. It has a wealth of custom pictures and even an install guide to putting hydraulics into an S-10.

Advantages: Hydraulics Lift - Since cylinders come in a lot of shapes and sizes, you have a lot of variety to choose from. Sizes range from 4-16 inches and up, so the amount of lift you get is determined by the length of the cylinder. Airbags are currently limited (in automotive applications) to 9 inches of lift at the most. You can get more lift out of a cylinder than a 'bag in a traditional setup, without resorting to mechanical advantage or cantilever lifts.

Ride - This is hotly debated, but a hydraulic setup can ride just as well as a factory Cadillac. In an S-10, you can do a coil-under up front with a separate shock, or even an accumulator. An accumulator is kind of like a shock absorber for hydraulics. It's a nitrogen-charged balloon contained inside of a casing, and turns the cylinder into a smooth riding machine.

Installation - It's a lot easier to mount a hydraulic cylinder than it is to mount an airbag. On most trucks it requires less cutting and less fabrication to get a cylinder in place than it does an airbag.

Instant power - Compressors take time to build up pressure, and batteries don't. Sure you have to charge batteries, but a once-a-week charge, or even never charging it with a Street charger, is a definite advantage when you want to lift and move quickly.

Disadvantages: Hydraulics Leaks - This is true to both methods, but leaks in hydraulics are more visible. Since hydraulic pumps use hydraulic fluid, if you have a leak you'll find oil somewhere. Oil can be messy to clean, and messy to work with, and that's one of the biggest reasons why people don't use hydraulics.

Weight - Batteries aren't light, and the average pump is 30-40 pounds. Put four batteries and two pumps in a truck, and you're looking at an easy 150 pounds of extra weight. If you're building something that you want to be fast, using hydraulics is probably not your best option.

Charging batteries - Batteries don't last forever. With average use, a hydraulic system can go from two weeks to a month without a charge, but it's still something you have to do. Some people aren't willing to do that.

How It Works: Airbags There's no doubt about it, 'bags have taken the lead in the 'bags versus juice debate. A lot of it was originally attributed to ride quality, but really the advantage is in the entry-level cost. For less than $500, you can have a simple 'bag setup with one compressor, a small tank, and paddle gauges, and you're good to roll until you can afford the fancy stuff. Airbags were originally developed to replace hydraulics in a lot of engineering situations. From cranes to heavy machinery to semi trucks, pneumatics replaced hydraulics. Airbags aren't invincible, but they do have a lot of advantages.

Airbags are pretty easy to understand. The airbag itself, or 'bag as it's more commonly known, is really an air spring. It's a variable-rate spring that's made of a thick rubber body. The 'bag easily compresses and when it's inflated, lifts to pick up your truck. Since the 'bag is a spring, the more pressure, the stiffer the ride.

Keep in mind that with air suspension, the airbag itself has a major weakness. If the 'bag isn't placed correctly, and the rubber body begins to rub against, it can burst under pressure, and drop the truck to the ground. This is very important to take in mind when mounting your 'bags, so be sure when they're installed to check for rubbing when they're inflated or deflated.

Advantages: Airbags Buy-As-You-Need Installation - One of the great things about airbags is the cost of getting into a system. For less than $200, you can put four 'bags into your truck, run some lines, put in a Schrader valve to full up your 'bags, and you're good to go. This is great for under-construction trucks, or people who just want to lift the frame to push around the shop. A little while later you get a tank and some valves, and you're cruising in style. It's a good budget build, and easier for people with a tighter wallet, at least in initial investment.

Ride - Sure you can get a hydraulic system to ride well, but 'bags generally ride great right out of the box. If you're not trying to hop it, and you've got the right shocks, you can ride like a Caddy all day long.

Weight - Four 'bags, eight valves, and two 6-gallon tanks all tolled weigh less than 100 pounds. If you want to go fast, weight is your enemy, and airbags may be the method you choose.

Disadvantages: Airbags Difficult Installation - An airbag is tricky. Since it's essentially a rubber bladder, you have to be sure that it's clear of anything that could rub it, or cause failure in the 'bag. If the 'bag rubs on anything, it will fail, and leave you stranded on the side of the road, and that's no good.

Speed - Unless you're running nitrogen, which costs you money to fill when you run out, your 'bagged truck is not going to beat a juiced car in a contest, especially not over a long period of time. Don't get us wrong, 'bags can be fast, but it costs money, and that may be a factor. How well do you want to know your local welding supply guy?

Amount of Lift - Airbags come in all sizes, diameters, and load ratings, but the largest one we've seen in a typical install is 9 inches of lift. That may be perfect for what you need, but if you're tucking a large rim and have a large body drop, take that in mind. Plus when you're maxing out that lift, the truck is going to ride like a brick.

Summary: Look, it really comes down to your choice, and your personal opinion. We're just here to give you the facts we have and let you make an informed decision. With that in mind, take a look at the buyer's guide. Inside, we've got products from some of the best manufacturers in the biz that are more than willing to help you in your search for the ultimate ride. No matter what you choose, remember that it's all about how low you are. Spark it or park it!

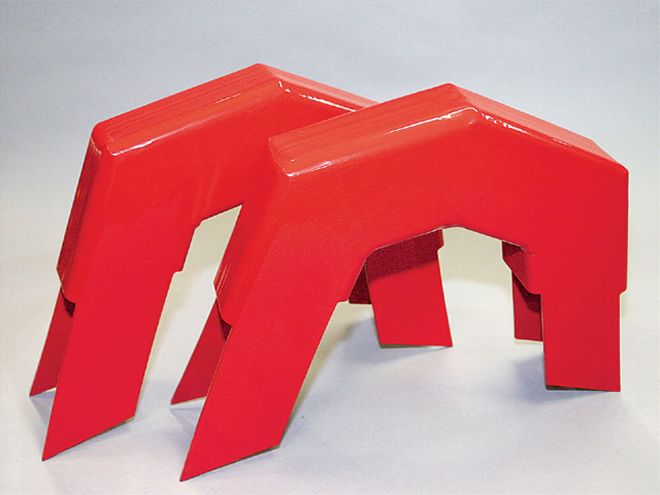

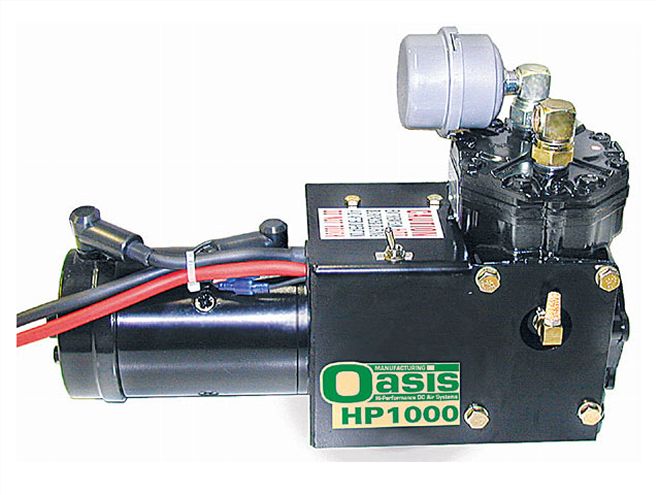

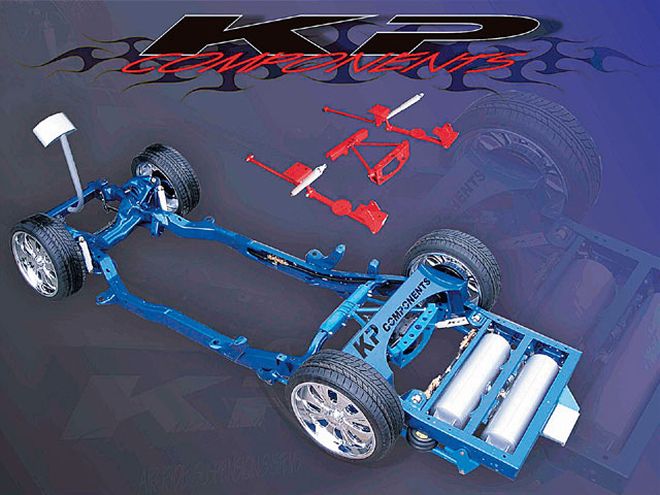

Airbag & Hydraulics Buyer's Guide You've got a lot of decisions to make in the world of adjustable suspensions, and we're here to help you. Whether you decide to use airbags or hydraulics, we've assembled a group of products to steer you in the right direction. From a basic bridge notch to the most complete hydraulic setup on the market, we've included it all in this guide. This is by no means every part available, so for more information, check out the Web sites listed, or call the manufacturers directly and they'll point you in the right way. Looking to lay out your truck and at the same time get some major lift? Look no further.

| airbag And Hydraulics Buyers Guide custom Truck Bed

There have been a lot of long-standing head-to-head competitions over time: Coke versus Pepsi, McDonald's versus Burger King, and hydraulics versus airbags. When it comes to adjustable suspensions, the debate never seems to end. Which method of lifting and lowering your truck is the best, and how do you know?

The thing is, comparing hydraulics with airbags is a little like comparing apples with oranges. Each method has its advantages, and its disadvantages, but they are significantly in their function. Because of that, we're here to help you make an educated decision in which method of adjustable suspension is best suited for you. We'll explain the advantages and disadvantages of each method. We're here to clear up the gunk.

A few things that you should know before doing either method:

| airbag And Hydraulics Buyers Guide custom Truck Bed

There have been a lot of long-standing head-to-head competitions over time: Coke versus Pepsi, McDonald's versus Burger King, and hydraulics versus airbags. When it comes to adjustable suspensions, the debate never seems to end. Which method of lifting and lowering your truck is the best, and how do you know?

The thing is, comparing hydraulics with airbags is a little like comparing apples with oranges. Each method has its advantages, and its disadvantages, but they are significantly in their function. Because of that, we're here to help you make an educated decision in which method of adjustable suspension is best suited for you. We'll explain the advantages and disadvantages of each method. We're here to clear up the gunk.

A few things that you should know before doing either method: