| 1. Whether you are looking for a mild performance grind or something to show taillights to that pesky Hemi Dodge Ram, Crane has the perfect cam for your 4.8L, 5.3L or 6.0L truck application.

Given the sheer number of LS engine enthusiasts, it's no surprise that industry leader Crane Cams recently introduced a number of new performance grinds for the LS market. We all know how well LS/LM and LQ applications respond to cam swaps, but what we didn't know was how these new Crane cams stacked up. So, what better way to find out than grab a couple of different Crane cams and run them on the engine dyno? The test procedure was a simple one. Build a suitable test motor then run it with three different cam profiles, starting with the stock cam and work our way through a pair of Crane grinds. Better to test a couple of different grinds than limit our testing to just one. Besides, we wanted to provide you with a choice of cam profiles, ranging from the smallest off-the-shelf offering to a (still streetable) performance grind. Crane offers even more aggressive profiles, but we purposely stuck with street grinds suitable for truck applications.

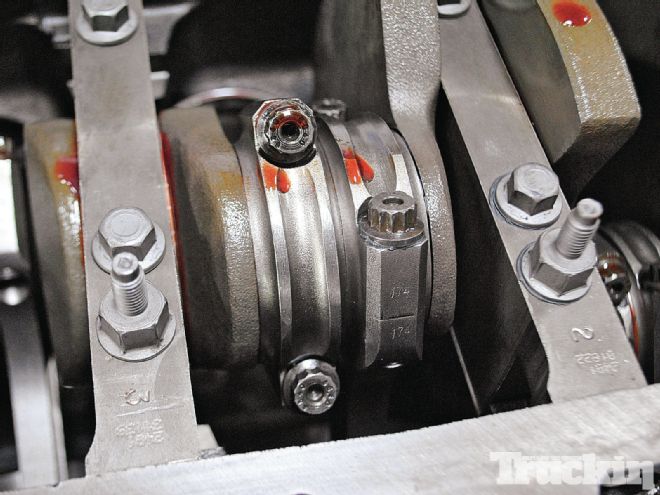

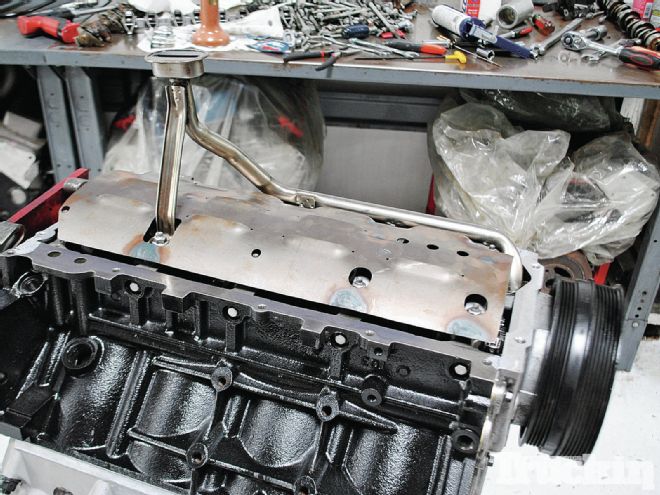

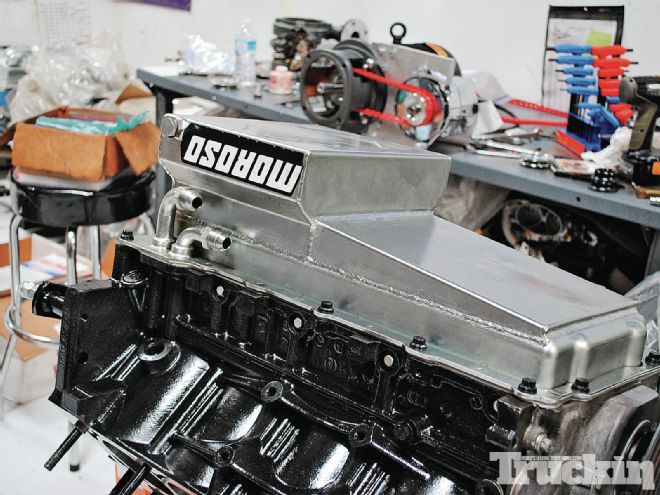

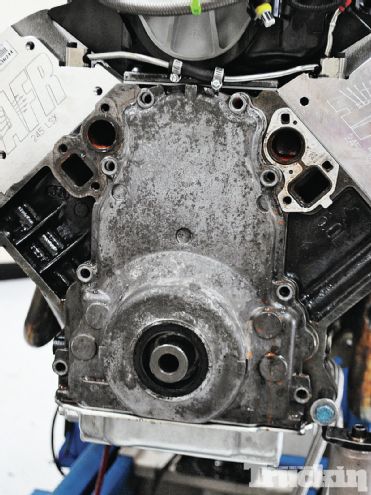

Our test engine started out life as an LQ4 6.0L truck motor, but it was upgraded to 408ci status thanks to a Scat rotating assembly. The stock 6.0L crank, rods and pistons were ditched in favor of forged internals from Scat and JE Pistons. The combinations included forged stroker crank and I-beam rods attached to a set of forged-aluminum slugs from JE Pistons. Each JE piston featured a 10cc dish replete with valve reliefs to provide adequate piston-to-valve clearance for aggressive cams. Aftermarket pistons won't be necessary for either of the Crane cams tested here, but we planned on using this test motor to run wilder cams in the future. Keeping the new 11.0:1 JE pistons sealed was machine work from L&R Automotive and a set of rings from Total Seal. The final touches to the 408ci stroker included a new Sealed Power oil pump combined with an oil pan, pickup and windage tray from Moroso. Though the Scat crank was keyed to accept an aftermarket damper, we relied on the stock unit for now.

| 2. Crane is back in action in a big way on the LS front, offering not only a variety of different (and powerful) cam grinds but also revised (strengthened) versions of their legendary Gold race rockers. We decided to put a pair of their new cams to the test on a stoker 6.0L truck motor.

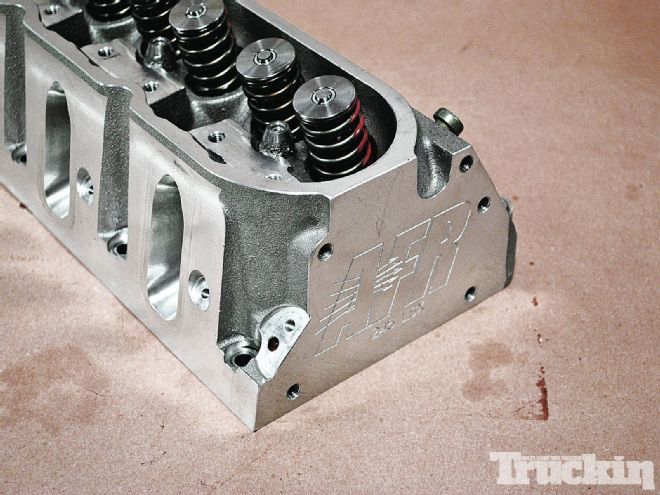

The short-block was obviously just part of the equation, as the components that really determine the power output included the cam, heads, and intake manifold. Recognizing this, we outfitted the stroker accordingly. For heads, we turned to Airflow research, who supplied a set of 245 LSX Mongoose heads. The AFR 245s offered impressive flow numbers and would be capable of supporting over 700 hp—more than enough for the mild cams we were testing. Finally, we bolted up a Fast LSXRT truck intake manifold, a set of 42-pound Fast injectors, a billet fuel rail and a 102mm throttle body. All testing was run through a set of 1¾-inch headers with precision tuning supplied by a Holley Dominator EFI system.

To start off the Crane Cam test, we ran the 408 equipped with the stock 5.3L truck cam. Depending on your resource, the 6.0L truck cam offers the same specs for early (pre-2000) LQ application but steps up to a .479/.467 lift split, a 207/196 duration and 116-degree LSA for post-2000 applications. The 207 cam specs would offer improved power over the milder 5.3L (and/or early 6.0L) version, but our 5.3L cam did provide a reasonable (stock) baseline to use as a comparison for the pair of Crane cams. Equipped with the stock 5.3L truck cam, the 408 stroker produced 449 hp at 5,100 rpm and 522 lb-ft of torque at 3,900 rpm. Tested on the engine dyno in this manner a stock 6.0L would produce around 400 hp. True to form, the stroker thumped out some serous low-speed torque, exceeding 500 lb-ft from 3,500 rpm to 4,600 rpm. The increased displacement and mild cam timing combined to limit peak power production, as the horsepower curve dropped off rapidly past 5,500 rpm. The stroker combination was practically begging for more cam timing.

First up was the mildest of the Crane offerings, part number 1449511. The Crane cam offered .500 lift (both intake and exhaust), a 206/214-degree duration split at .050 and an EFI and idle-friendly 114-degree LSA. The Crane catalog listed the cam as great for a daily driver or towing for 4.8L to 5.7L applications (obviously including the larger 6.0L). The Crane catalog also indicated that the cam did not require a valvespring upgrade nor were ECU mods necessary. However, given the sizeable power gains, we suspect a tune would better optimize the combination. Swapping the cam on the engine dyno was a snap and the results were more than worth the effort. The mild Crane cam improved the power output of the 6.0L stroker from 449 hp to 515 hp at 5,400 rpm and torque increased from 522 lb-ft to 556 lb-ft of torque at 4,500 rpm. A true indication of a great street cam choice was the fact that the 206 grind improved the power output everywhere, from 2,600 rpm to 6,000 rpm. The extra 66 hp and 34 lb-ft of torque came with a minimal drop in idle vacuum, from 22 inches to 21 inches (hardly noticeable). This was an excellent cam choice for a daily driver, even a smaller 4.8L, though the cam would peak at a higher engine speed on the smaller motor.

| 6. To establish a baseline, the 408ci stroker motor was assembled with the stock truck cam. We did not have a 6.0L cam, so we substituted a 5.3L version we had at our disposal. The gains offered by the stock 6.0L cam would be minimal.

After witnessing the gains offered by the mild 206 cam, we were naturally anxious to stick in the wilder 224 cam (PN: 1449121). The more aggressive Crane cam increased lift to .590 (both intake and exhaust) and the duration split to 224/232 degrees, while the LSA widened slightly to 115 degrees. Healthy to be sure, but totally streetable. On this larger 408ci application, the increased duration dropped the idle vacuum to 18.5 inches but still well in the acceptable range for any EFI application. What the 224 cam did offer was power, and lots of it. Equipped with the 224 cam and tuned to perfection by Westech's Ernie Mena, the 408 produced 584 hp at 5,700 rpm and 566 lb-ft of torque at 4,700 rpm. Note that both Crane cams increased the engine speed where the engine produced peak power, but the huge power gains at the top of the rev range came with very little trade off at lower engine speeds. Who wouldn't trade 10 lb-ft down at 2,600 rpm for the extra 136 hp? Those are the kind of gains normally associated with forced induction, and the fact that it came with little or no penalty down low is just icing on the cake. If these LS cams are any indication, it looks like there is plenty of power hiding in Crane's little black boxes.

| 1. Whether you are looking for a mild performance grind or something to show taillights to that pesky Hemi Dodge Ram, Crane has the perfect cam for your 4.8L, 5.3L or 6.0L truck application.

Given the sheer number of LS engine enthusiasts, it's no surprise that industry leader Crane Cams recently introduced a number of new performance grinds for the LS market. We all know how well LS/LM and LQ applications respond to cam swaps, but what we didn't know was how these new Crane cams stacked up. So, what better way to find out than grab a couple of different Crane cams and run them on the engine dyno? The test procedure was a simple one. Build a suitable test motor then run it with three different cam profiles, starting with the stock cam and work our way through a pair of Crane grinds. Better to test a couple of different grinds than limit our testing to just one. Besides, we wanted to provide you with a choice of cam profiles, ranging from the smallest off-the-shelf offering to a (still streetable) performance grind. Crane offers even more aggressive profiles, but we purposely stuck with street grinds suitable for truck applications.

| 1. Whether you are looking for a mild performance grind or something to show taillights to that pesky Hemi Dodge Ram, Crane has the perfect cam for your 4.8L, 5.3L or 6.0L truck application.

Given the sheer number of LS engine enthusiasts, it's no surprise that industry leader Crane Cams recently introduced a number of new performance grinds for the LS market. We all know how well LS/LM and LQ applications respond to cam swaps, but what we didn't know was how these new Crane cams stacked up. So, what better way to find out than grab a couple of different Crane cams and run them on the engine dyno? The test procedure was a simple one. Build a suitable test motor then run it with three different cam profiles, starting with the stock cam and work our way through a pair of Crane grinds. Better to test a couple of different grinds than limit our testing to just one. Besides, we wanted to provide you with a choice of cam profiles, ranging from the smallest off-the-shelf offering to a (still streetable) performance grind. Crane offers even more aggressive profiles, but we purposely stuck with street grinds suitable for truck applications.