| ultiamte Tow Rig Part 2 Smart Power towing Rv Trailer

We began the build of our F-250’s 7.3L Power Stroke in the last issue of RV. We tore off the front clip and disassembled the engine down to the heads, all in preparation for a Banks rebuilt turbo, new DieselSite High-Pressure Oil Pump (HPOP), Banks intercooler, and more. The turbo is done, the HPOP is installed, and a few oil leaks have been taken care of, so now it’s time to finish the build and tie up the loose ends.

Cold Air

The Banks Techni-Cooler Intercooler is an investment in keeping the engine alive, allowing it to pull stronger and longer up those steep grades. When the intake air is compressed by the turbo charger, it gets hot from all the extra molecules running into each other. Hot air is less dense than cold air, which is why heat rises and cold sinks. This lighter, less dense air will not hold as much fuel for combustion as cold air will. This will cause incomplete combustion, meaning less power and fewer miles per gallon.

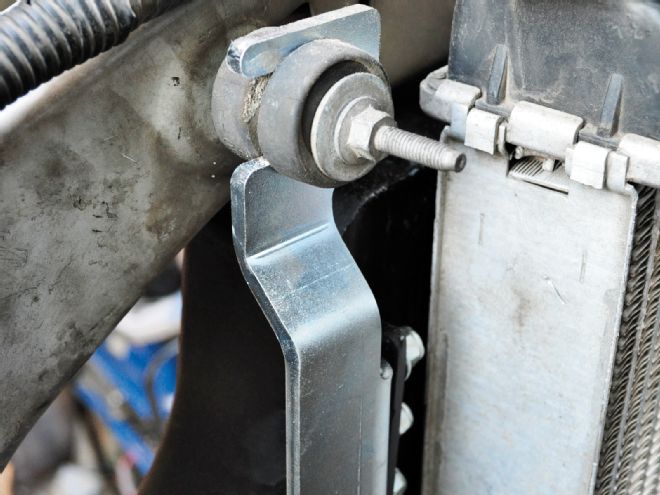

| Getting ready for the Banks Techni-Cooler intercooler.

The intercooler’s job is to rid the charged air of this heat. It’s pretty much a radiator for hot air. As the turbo compresses the air, tubes divert it into the intercooler instead of sending it directly into the engine. From there, another tube then takes the cold air and sends it to the engine, allowing for the aforementioned better power and better economy, as well as lower EGTs.

The Banks Techni-Cooler Intercooler comes with larger intake tubes to reduce restriction, plus the intercooler itself is built with larger side tanks that reduce restriction by 18 percent and allow for more even heat dissipation across the intercooler. All these changes make for a much more efficient cooler than the truck was equipped with from the factory.

With a better intercooler onboard, a more efficient turbo, and a high-flow exhaust, the factory intake is the only restriction left. Banks Power’s Ram Air intake has been designed (and tested true) to flow better than stock and other intakes, but more importantly, to give the engine cold, clean, and dense air. It’s all about cold dense air if you haven’t gathered that already.

Coolant Filtration

The 7.3L is a “sand cast” engine. This means sand is used to create all the oil and coolant galleries in the engine’s block during the casting process. While the factory tries to remove the sand, they’ll never get it all. Even if all the sand is miraculously vacated from the block at the factory, this sand slowly leaches out of the casting over time, putting it right back into the coolant system. The sand wreaks havoc on seals, water pumps, etc., causing high replacement intervals and an overall decreased engine life. Again, if somehow all the sand is removed, there is another problem—many coolant additives required to halt cavitation or add lubrication will build up on the walls of the powerplant’s passages. These growths will flake off, plugging passageways, and will cause the same sort of damage sand will.

| DieselSite’s coolant filter ties in-line between the coolant reservoir and a fitting near the thermostat housing.

The fix is a good coolant filtration system. All the big rigs, buses, tractors, and boat motors have one; it’s not a new technology by any means. We turned to the diesel engine pros at DieselSite for help. They recommended a kit using a fully billet manifold that mates to a very common (and quality) coolant filter, found at just about any truck stop or auto supply store. The kit came with all the fittings and hoses needed to get the job done the right way. With this kit, the 7.3L’s coolant system is ready for another half million miles of service.

| Here’s the DieselSite coolant filter installed, and it is easily accessible for filter changes.

Thermostat

The 2001 7.3L from Ford is equipped with a 195-degree thermostat. From International (the 7.3L’s actual manufacturer), it’s got a 203-degree unit under the hood. Originally, the 7.3L came with the true International thermostat. That is until 1996, when Ford changed the water pump. The correct thermostat would not fit in the new pump, so Ford went to a 195-degree thermostat. The problem is that diesels run more efficiently at 200 degrees. While it’s not a huge difference in temperature, it makes a huge difference in how well the engine performs. The guys at DieselSite describe it the best: “For anyone who doesn’t think 8 degrees can make a difference, consider that at 211 degrees, water is hot, and at 212 degrees, it’s converted to vapor. At the right critical point for every matter on earth, a degree or a few degrees can make a huge difference.”

| The factory thermostat housing corrodes extremely fast. DieselSite’s fix is a billet aluminum part. We also changed the thermostat to a 203-degree unit to help the engine run as International intended.

Another problem area is the factory thermostat housing. It’s made out of cheap, stamped steel and corrodes extremely fast. It was designed as a throwaway part, meant to be changed often. Our original reason for this rebuild (besides the high mileage on the truck) stemmed from what we thought was a leaking timing cover. As it turned out, it was the thermostat housing.

DieselSite has a fix for both problems. While the original thermostat from International cannot be installed in the new Ford pump (it blocks off certain coolant passages and won’t seal correctly), DieselSite has made a new one that will fit. So we picked up a new thermostat, as well as a billet aluminum housing for it, from DieselSite. The new housing will outlast the engine and the thermostat will get the rig running like it was meant to.

-

-

Testing

After the install, the truck started and idled ions smoother than before. After a few break-in miles, we headed to storage and picked up our Carson Trailer Mobile Test Lab. From there, we took the long route through the hills to a local shutdown airbase, MCAS El Toro, to finish our test drive with a good acceleration test.

The turbo spooled up almost instantly through the hills, giving us much more boost to work with at lower rpms. Previously, the turbo’s wastegate was not strong enough to contain the boost under heavy load, causing us to downshift and lose momentum. Now with the Banks Big Head wastegate actuator, the turbo can do its job correctly with the boost going to good use. Throttle response has greatly increased thanks to the whole package, but mainly from the stronger HPOP from DieselSite, we’re sure.

With all the upgrades working together in perfect unison, this truck, no joke, has more power than we feel we could ever need. But we did not build a race truck here. The power is extremely smooth, not violent at all. Everything we’ve done to the engine was done 100 percent in the interest of towing capability and more importantly, reliability. This is one of those builds that turned out better than we ever expected. The crews at DieselSite and Banks Power really know their stuff, and we most definitely recommend them.

Head to www.rvmagonline.com for more photos from this build, plus a few videos from our long day of testing at MCAS El Toro.

| ultiamte Tow Rig Part 2 Smart Power towing Rv Trailer

We began the build of our F-250’s 7.3L Power Stroke in the last issue of RV. We tore off the front clip and disassembled the engine down to the heads, all in preparation for a Banks rebuilt turbo, new DieselSite High-Pressure Oil Pump (HPOP), Banks intercooler, and more. The turbo is done, the HPOP is installed, and a few oil leaks have been taken care of, so now it’s time to finish the build and tie up the loose ends.

Cold Air

| ultiamte Tow Rig Part 2 Smart Power towing Rv Trailer

We began the build of our F-250’s 7.3L Power Stroke in the last issue of RV. We tore off the front clip and disassembled the engine down to the heads, all in preparation for a Banks rebuilt turbo, new DieselSite High-Pressure Oil Pump (HPOP), Banks intercooler, and more. The turbo is done, the HPOP is installed, and a few oil leaks have been taken care of, so now it’s time to finish the build and tie up the loose ends.

Cold Air