In the previous two installments, we cammed our Ram and then followed up with a stroker kit in an effort to increase torque production. Both routes were ultimately successful in elevating the torque curve over the factory components. It wasn’t until the installation of the wilder custom hydraulic roller cam in Part Two that we started sacrificing low and midrange torque in a quest for top-end power. Cam timing usually has the effect, as ideal cam timing to maximum peak power is not the same as ideal cam timing to maximize torque production. The question is one of engine speed—or more specifically where do you want your torque curve generated? Wilder cam timing effectively shifts the torque curve higher in the rev range. The upside is increased top-end power, but the penalty of the shift is a loss in not only low-speed torque production, but likely overall drivability as well. The ideal world would be to have the power offered by both, or better yet, more power everywhere. Time to get PSIched!

| When it comes to building torque, the best replacement for displacement is boost.

As effective as the cam upgrade and even stroker short-block were, they actually pale in comparison to artificial aspiration, better known as boost. When it comes to boost, there are many available options, including multiple forms of supercharging and turbocharging. Every form has its strengths and weaknesses, but compared on a boost-to-boost basis, nothing beats the turbo. Blower guys will always chime in about the immediate boost response, which can be beneficial on low-speed truck applications where torque production is favored over peak power. Sized properly, a turbo can offer nearly as much low-speed power (torque) as a comparable supercharger, and do so at lower boost levels. The major benefit the turbo enjoys over the blower is the lack of parasitic losses associated with driving the blower. Power is required to drive any supercharger, the greater the blower speed and airflow supplied by the blower, the more power required to drive it. The power required to drive the blower is power not available to propel the vehicle, thus a supercharger must produce enough extra power to first offset that which was required to produce said power.

By comparison, a turbo is essentially given a free ride. On a normally aspirated or supercharged application, the exhaust (and heat) energy is simply allowed to escape to the atmosphere. On a turbo application, a portion of the otherwise wasted exhaust energy is used to spin the turbine wheel, which in turn spins the compressor wheel. The compressor wheel is what supplies additional airflow to the engine. Unlike the supercharger, very little power is consumed in this energy conversion, so the turbo does not suffer the same parasitic losses. The end result is that (properly sized), the turbo will always provide more power per pound of boost than a comparable supercharger. Of course, the turbo will not offer the immediate boost response of the positive displacement (roots or twin screw), but (for some) the extra power is worth the trade off.

| The 5.7L Hemi stroker featured a forged crank, rods and pistons from Scat to produce a bulletproof bottom end. The .020-over, (small dome) forged pistons from Probe Racing combined with the 3.795-inch forged steel crank and 6.215-inch 4340 forged steel connecting rods. Total Seal provided the ring package for our Hemi stroker combination. Note also the Fel Pro MLS head gaskets and ARP head studs

For our needs, we decided that it was all about power, or at least enough about power that we chose to turbocharge the 5.7L stroker rather than add a blower. This stroker is every bit as suited to a supercharger as a turbo, and who knows, maybe a blower test is in the cards, but for now, its all about the turbo. For the do-it-yourselfer out there, a turbo kit can be as simple as plumbing all the exhaust to the turbo. For a single turbo system, this means joining the exhaust from each bank into some sort of Y-pipe. We have used the stock truck manifolds before with great success, but for this application and turbo kit from HP Performance, we ran the SRT8 exhaust manifolds. The factory manifolds offered exceptional heat retention, making them ideal for turbo applications. The kit from HP Performance was designed for a 300, but they also offer a similar system for Hemi-powered trucks. Wanting to try a pair of different turbos, we elected to first attach an affordable turbo from CXRacing to the hot side of the turbo kit. Do the cost-effective turbos really work? That was one of the questions we hoped to answer.

| 8. For street use, power and boost levels, the kit from HP Performance was supplied with a single 38mm wastegate. The loads imposed on the engine dyno combined with our elevated power levels required an upgrade. Luckily Turbo Smart supplied one of their trick, new Hyper-Gate45s. The lightweight wastegate featured a revolutionary new collar locking design that both helped reduce size (to ease fitment) and speed up spring changes.

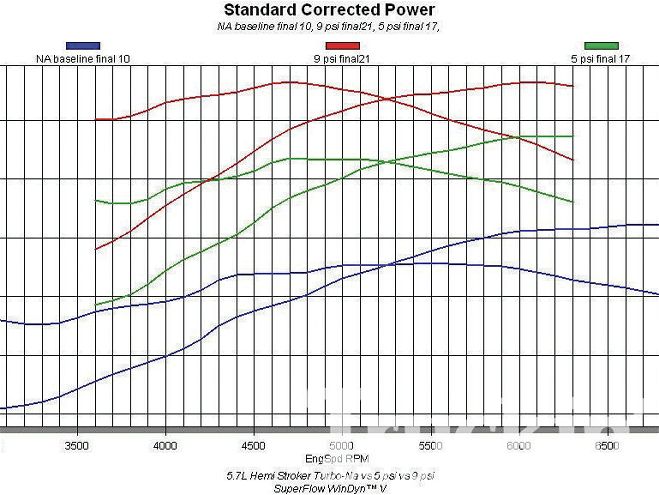

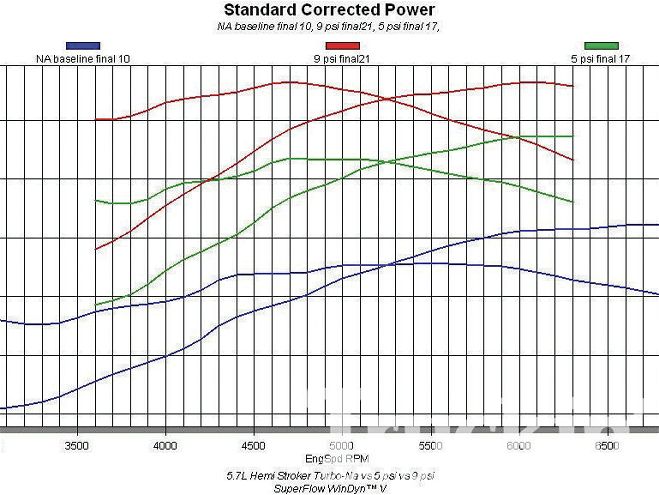

In addition to the 76mm turbo, CXRacing also supplied an air-to-water intercooler. The kit from HP Performance included an air-to-water, but (like the turbo) we wanted to check the cost-effective turbo components while we had the motor on the dyno. The turbo kit from HP Performance was originally supplied with a 38mm wastegate, but we elected to take this opportunity to upgrade to a 45mm HyperGate from Turbo Smart. The new HyperGate not only offered additional flow for better boost control, the new wastegate also featured a revolutionary new locking collar mechanism that made spring changes a snap. The compact design eased installation in tight (read late-model) engine compartments. Turbo Smart also supplied one of their manual wastegate controllers to allow us to dial up the boost above the minimum wastegate setting of 6 psi. Tuned to perfection using the XFI/XIM management system from Fast, the turbo stroker pumped out 672 hp and 635 lb-ft of torque at 5.7 psi. Adding 150 hp to our stroker was impressive, but we were just getting started.

| 9. The first turbo tested came from CXRacing. The 76mm turbo combined price and performance as the affordably priced turbo offered impressive boost response and more than enough power for most street applications.

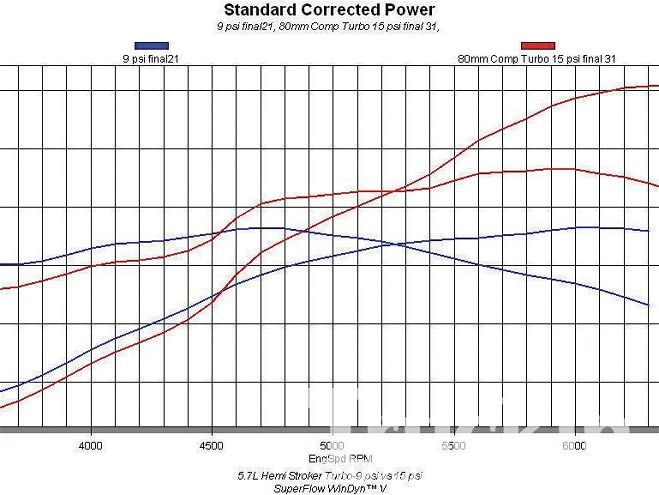

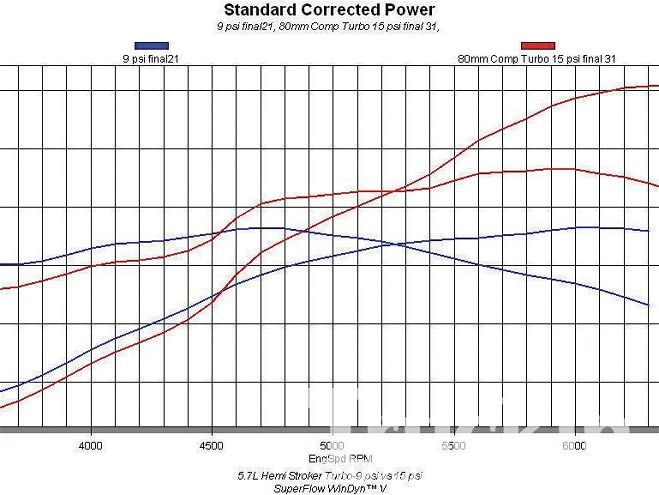

After success at the lower boost levels, we cranked it up to nearly 9 psi. The increase in boost elevated the entire power curve, pushing the peak numbers to 765 hp and 764 lb-ft of torque. Things were starting to get serious, but we feared the smaller turbo from CXRacing was running out of steam. To cure this problem, we stepped up to an 80mm unit from Comp Turbo. The larger turbo was installed and run through the same air-to-water intercooler. We meticulously tuned the combination and increased the boost until we reached more than 15 psi. Subjecting the motor to an additional atmosphere of pressure resulted in a serious jump in power. The turbo Hemi stroker produced 1,015 hp and 867 lb-ft of torque. Nothing short of an all-out race truck is going to require any more power, but the combination does illustrate what happens when you add boost to an already potent stroker Hemi. To say we were excited about the turbo stroker Hemi would be an understatement—we were PSIched!

| 10. We also relied on an air-to-water intercooler from CXRacing. The intercooler was less necessary at the lower boost levels, but both improved power and reduced the likelihood of harmful detonation. Though additional power is available with ice water, dyno water was used for all testing.

| 5 7 Hemi Performance Cam Swap Part 3 dyno Graph 9vs5psi

| 5 7 Hemi Performance Cam Swap Part 3 dyno Graph 9vs15psi

| 5 7 Hemi Performance Cam Swap Part 3 dyno Graph 9vs5psi

| 5 7 Hemi Performance Cam Swap Part 3 dyno Graph 9vs5psi

| 5 7 Hemi Performance Cam Swap Part 3 dyno Graph 9vs15psi

| 5 7 Hemi Performance Cam Swap Part 3 dyno Graph 9vs15psi