Back in 1999, The Turtle Expedition began building The Turtle V, based on an '99 Ford F-550. One thing always bothered us, though. When we were really demanding power from the 7.3L Power Stroke, there was this cackling or chuffing noise from the engine. At the time, Steve Benson, owner and engineer at ATS, told us it was air rattling around in the turbo.

| ATS Aurora 3000 Turbocharger 1999 Ford F550

Since the recent release of upgrade components for the 7.3L Power Stroke (model years '99 1/2 to '03), owners of these trucks have heard this noise and felt the lack of performance in one particular area: airflow. Due to the proprietary design complexity of the mounting hardware for the factory turbo, very little has been available until now to upgrade the system.

ATS Diesel Performance has recently introduced its line of complete bolt-on turbo kits for this engine with the Aurora 3000, 4000, 5000, and 6000 configurations. While we were hesitant to replace the factory turbo, after consulting with Ken Imler, owner of Imler Diesel Performance in Sacramento, California, moving up to the new ATS system seemed like a safe choice, at least in terms of reliability.

The Aurora 3000 was designed as a quick-response, high-pressure-ratio turbo, intended for everyday driving and heavy towing. The Turtle V, with its custom Tortuga Expedition camper, tipped the scales at around 14,000 pounds. The Aurora 3000 would be a good match, providing increased airflow to the engine with quick power delivery while maintaining low EGT. The Aurora 3000 kit includes everything: turbo, pedestal, up-pipes, downpipe, intake manifold, intake tube, heavy-duty silicone boot, and all necessary hardware (Part# 202-930-3224).

| The Aurora 3000 kit includes everything: turbo, pedestal, up-pipes, downpipe, intake manifold, intake tube, heavy-duty silicone boot, and all necessary hardware. (Part# 202-930-3224) The Aurora 3000 was designed as a quick-response, high-pressure-ratio turbo, intended for everyday driving and heavy towing.

The pedestal was designed to employ clockwise-rotation turbochargers. Clockwise-rotation turbochargers are available in many different frame sizes. For the 7.3L, ATS can supply Aurora turbochargers that are rated for 65 lb-min all the way up to 105 lb-min.

A very complete installation manual comes with the Aurora turbo, but this is not a job for the do-it-yourself crowd. We felt safer watching the skilled hands of Steve Scott at the Ken Imler Diesel Performance center. Steve has done many turbo swaps and knew the process well.

His first step was to take the lower part of the exhaust off the manifold and cut the downpipe. Moving to the top, he removed the hump hoses, intake plenum, intake air tube, and lifted out the stock turbo. The sensors, which were disconnected, were reinstalled later. Steve pointed out that the warm-up butterfly valve, along with its leak-prone solenoid-actuated plunger and oil supply, would be eliminated on the new turbo.

Looking at the crossover pipe, we could see there had been exhaust leaks on both sides. It's a common problem with the doughnut seals from the factory. After time, they dry out and crack. ATS remedies this by using a welded flange, leak-free metal gaskets, and a flexible connector on the downpipe.

The small freeze plug in the engine valley in front of (and just under) the turbo was a leftover from early models of the Power Stroke engines when a cam-actuated fuel pump was used. They later went to electric. This plug was pried out, as the hole would be used for the new oil return off the ATS turbo.

The solid fuel-return line coming off the fuel rail on the passenger-side head was replaced with a flexible line. The OEM solid line interferes with the ATS mounting plate. New O-rings were installed for the supply and return under the baseplate. Now the turbo stand could be mounted, and the downpipes attached and loosely secured from underneath.

These presented a bit of a problem, because ATS uses 13mm bolt heads instead of the factory 10mm, and there was not enough room for a socket. The bolts were also a little too long to pass the bend in the manifold—both minor inconveniences. Steve simply reversed the bolts and put the nuts on top. To our advantage, the new downpipe was larger in diameter and a perfect match for our MagnaFlow Performance exhaust. That will certainly increase airflow.

Now the turbo itself could be temporarily installed loosely so that the return oil drain could be located, pre-bent to the correct angle, and attached to the turbo on the bench. With that done, the turbo was pre-oiled and reinstalled. Steve had previously clocked it to line it up with the intake manifold. All bolts on the inlet and outlet housing were then fully tightened.

The tube from our K&N air filter to the intake and plenum were positioned. Ports for boost air temperature and the MAP sensor were installed, along with the air heater on the bottom. The trim cover over the fuel filter needed to be trimmed slightly to fit correctly. The ATS may have been designed for a single alternator setup, so there was a clearance issue near the auxiliary alternator ground connections. It just required relocating a couple of wires.

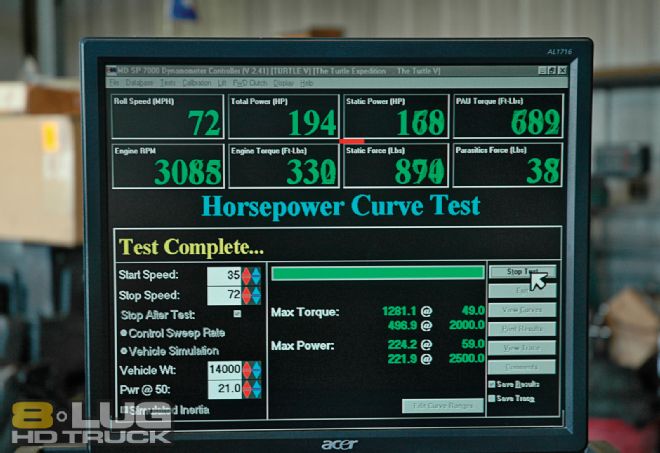

After double-checking everything, we went back to the dyno. Our pre-installation run in the stock level had given us 197 hp and 413 lb-ft of torque, with an EGT of 1,075 degrees. Steve said that was pretty normal, considering the weight of The Turtle V with its 40.7-inch tires. Setting the Edge Juice to Level 3, horsepower jumped to 224 and torque to 476 with an EGT of 1,150.

With the ATS Aurora 3000, our stock run produced 195 hp and 427 lb-ft of torque with an EGT of 930—a significant drop in exhaust gas temperature. With the Edge Juice again set at Level 3, horsepower was 225, and torque came up to 496 with EGT at 1,015—a full 135 degrees lower than we saw with the factory turbo at the same settings.

Looking at those numbers, there was little increase in horsepower, but a healthy increase in torque, and perhaps most impressive, a significant drop in the EGT.

Out on the road, a seat-of-the-pants feeling told more. Remember, this is not a race truck. We previously had our automatic boost level warning on the Edge Attitude set to a conservative 17 pounds, which was usually easy to maintain. Ken Imler said our 7.3L Power Stroke, bone-stock, could safely handle up to 35 pounds. That's good, because the new ATS spools up so quickly compared to the stock turbo, that we found ourselves at 25 pounds while just accelerating off a stop sign. The engine responded accordingly.

Bottom line: We gained all-important reliability, eliminated two exhaust leaks and a pesky oil leak, lowered our EGT across the board, gained more torque, and noticed better response off the line. Looking at the numbers and the weight of our truck (14,000 pounds) and its tires, Ken was pleased with the increase in torque and was pleasantly surprised by the drop in EGT. Dyno graphs showed that, aside from peak power and torque, power was improved throughout the low-to-mid-range rpm and speeds.

He said a stock, empty, '99 Power Stroke with normal rubber would see higher increases in both horsepower and torque.

We're certainly not complaining, but it did prompt us to swap our Auto Meter boost gauge—previously never reaching its limit of 20 psi—for a model that goes up to 35 psi, and our max boost warning signal has been upped to 25 psi. When we hear it, we smile.