| cat Back Vs Turbo Back duramax Burnout

Since the dawn of diesel performance, aftermarket tuners have made it clear that generating horsepower is predicated on the ability to remove spent exhaust gases quickly and efficiently. As a diesel's exhaust gas temperatures (EGTs) are lowered, more fuel and air can be added to produce more power and torque. While there are a number of limiting factors in producing power-such as injector efficiency, adequate fuel supply, and boost-it's high EGTs that generally pose the greatest threat to a diesel's longevity.

Have you ever wondered if a full turbo-back exhaust is really better than a catalytic converter-back system? We were wondering the same thing, so we got on the horn with Advanced Flow Engineering and ordered up two exhaust systems. The first was a complete turbo-back system, which utilized 4-inch mandrel-bent tubing from the turbo all the way back to the tip and incorporated a stainless 8x30-inch muffler. The second system was a slightly less expensive cat-back system, which utilized the stock downpipe and catalytic converters.

"We spend a great deal of time designing each system for optimal backpressure and maximum flow," said Jimmy Bajza, mechanical engineer at AFE. "We've found that bigger is not always better, especially in downpipe design. The quickest way between two points is a straight line. We use this same simple principle when designing our exhaust systems."

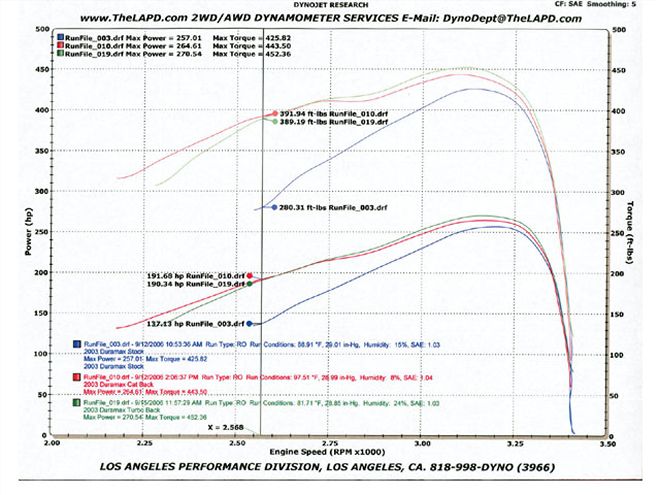

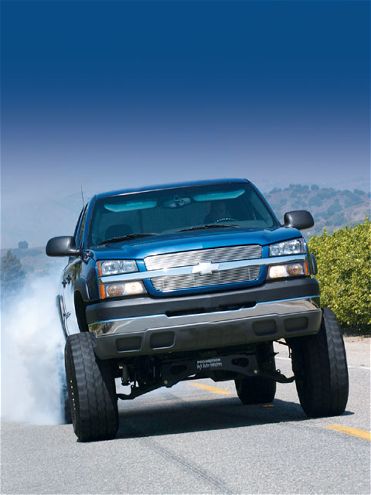

Before we removed the OE exhaust, we took our '03 Duramax to L.A. Performance Division for a little truth-or-dare on their Dynojet dynamometer. To our surprise, the bone-stock '03 put down 257 hp and 425 lb-ft of torque at the rear wheels-respectable numbers for a stock turbodiesel. Just a few hours later, we had the stock tank-like exhaust off and the stainless steel AFE system in place. The moment of truth had arrived, and we fired the truck up, awaking the sleeping dragon. The 6.6L put down 264 hp and 443 lb-ft of torque for peak power. What amazed us the most was the improvement at 2,500 rpm. In stock configuration, the Duramax produced 280 lb-ft of torque. With the new exhaust in place, it produced 389 lb-ft of torque at the same rpm. Just in case the dyno was lying, we put down a set of 200-foot rubber stripes at an undisclosed location to gather additional scientific data-really!

On day two of our test, we removed the downpipe and stock catalytic converter. In its place we installed the AFE downtube, which is integrated into an off-road test pipe. On the dyno we found an additional 6 hp and 9 lb-ft of torque. In addition to the power improvements, we shaved some weight and gave the Duramax a throaty tone out of the tailpipe.

Our conclusion: Turbo-back systems produce more peak power and torque than cat-back systems but sacrifice a very small amount of midrange power. If you're interested in pulling out all the stops, go with the turbo-back. If you'd like to save a few dollars and like the tone of your stock exhaust, the cat-back's got your name on it.

| cat Back Vs Turbo Back duramax Burnout

Since the dawn of diesel performance, aftermarket tuners have made it clear that generating horsepower is predicated on the ability to remove spent exhaust gases quickly and efficiently. As a diesel's exhaust gas temperatures (EGTs) are lowered, more fuel and air can be added to produce more power and torque. While there are a number of limiting factors in producing power-such as injector efficiency, adequate fuel supply, and boost-it's high EGTs that generally pose the greatest threat to a diesel's longevity.

| cat Back Vs Turbo Back duramax Burnout

Since the dawn of diesel performance, aftermarket tuners have made it clear that generating horsepower is predicated on the ability to remove spent exhaust gases quickly and efficiently. As a diesel's exhaust gas temperatures (EGTs) are lowered, more fuel and air can be added to produce more power and torque. While there are a number of limiting factors in producing power-such as injector efficiency, adequate fuel supply, and boost-it's high EGTs that generally pose the greatest threat to a diesel's longevity.