| 0554 Dp 62 35 Z

They are plentiful, they are durable, and they are cheap. In addition, they're simple and economical. Those five factors are what make the venerable 6.2L Chevrolet diesel a very popular builder these days, especially if you are planning on plopping one under the hood of an older 1/2-ton pickup or SUV in place of a gas V-8. The engines were a mainstay in the '82-'93 GM light-duty truck line under the hoods of Chevrolet and GMC pickups, Suburbans, and fullsize vans. The 6.2L was replaced in 1994 by the 6.5L, which was subsequently replaced by the Duramax 6600 in 2001.

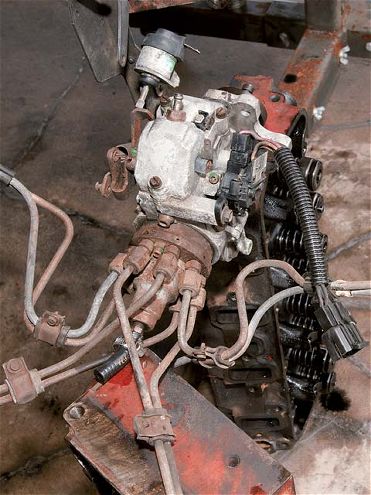

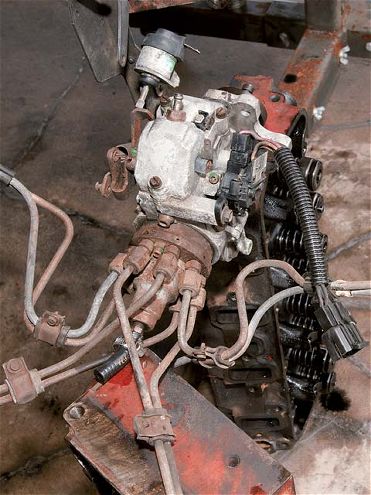

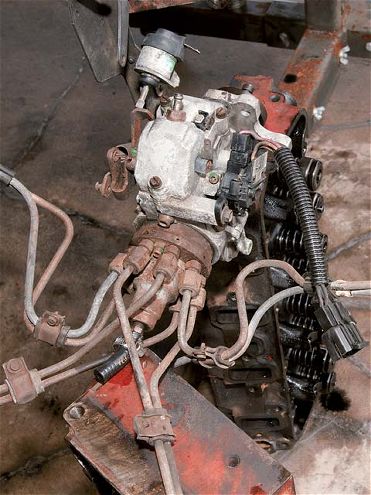

| This is the '82 C1500 that donated its 6.2L to our cause. The engine wasn't running because the owner had melted off the glow plug's tips and couldn't figure out how to remove them without removing the heads. The engine had less than 200,000 miles on it. We bought the whole truck for $500.

Finding a Good Donor

Even though they have been out of production for nearly a decade, there are still a lot of 6.2Ls on the road-and countless others sitting idle that could easily be put back on the road. What that means to the diesel-loving do-it-yourselfer is if you are in need of a good diesel engine for your older pickup or SUV, you can find the 6.2Ls with little effort. They are lying around everywhere you look. Literally. If you spot an old, beat-up GM pickup or big van sitting beside a barn, wedged in the farthest row of junkyard dogs, or serving as a trellis for a growth of blackberries, it probably has a 6.2L diesel under the hood. These parts trucks are fine for just that-parts. But, the ones you probably want to check out for rebuilding the diesel are not those rusting away, but rather those listed in the used vehicles section of any newspaper. You know the ones-those old GM diesel pickups that still run and can be had for less than the price of a set of new tires, or better yet, are being given away.

Many of these bargains are parked either because the truck around the engine has fallen apart or the engine itself, as the owner sees it, was nearing the end of its life and the owner simply moved on to other modes of transportation rather than deal with the cost of rebuilding either the truck, the diesel, or both. Believe it or not, most of the time, these trucks are being parted with because they will not start in cold weather because of a problem with the glow plugs or bad relays. If the truck isn't rusted completely into the ground and the engine hasn't been sitting under water, one person's junker becomes a diesel builder's treasure.

Builder/Buyer Beware

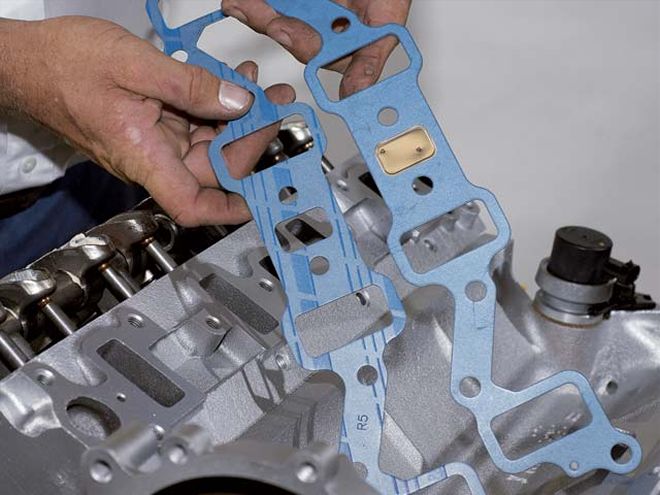

The caveat to this entire 6.2L rebuilding process rests on one thing: the year of the engine you use as your base. Heed this advice: If the engine you are contemplating as the builder is pre-'88, find a newer engine for the best performance and reliability from the rebuild at the cheapest price. As Warren Spears, the owner and co-builder of this project says, "If you raise the hood of the donor vehicle and you don't see a serpentine belt system, rapidly close the hood, thank the person for showing you the vehicle, and quickly walk away." We found that out the hard way on this rebuild. Our junkyard '82 C1500 diesel pickup cost $500. Warren sold the truck for parts, sans engine, for $400, so the C-model 6.2L ended up costing $100. However, as much of a bargain that was, it cost an additional $1,900 to upgrade the engine to the higher-performance, more reliable J-model by the time we bought reworked, later-model ('90-'92) heads for $900, the newer-model rocker arm assemblies for $200, and the brackets and drive accessories to convert the engine to the serpentine-belt drive for $800. That doesn't include the aggravation and time involved tracking down the better parts and figuring out how to upgrade the engine to the more reliable, later-style 6.2L. "We'd had been far better off spending $2,000 on a '93 model that had a good body and the latest version of the 6.2L," reminisces Spears. "But, hindsight, as they say, is always 20/20." Thankfully, Warren had several aces-in-the-hole. One was at the local Chevy dealer. Daryl "Woody" Woods, a superb parts counterman at DeRussy Chevrolet in Bay St. Louis, Mississippi, took the time and knew where to find all the parts to make the upgrade. The other great help in this rebuild was our local O'Reilly Auto Parts store in Long Beach, Mississippi, where Jason Carey, the store's manager, provided similar parts assistance, including providing a Federal Mogul Premium Master Engine rebuild kit-and a number of other must-have items that cropped up along the way.

Without those two guys, "The Diesel Page 6.2L Diesel Engine" reference manual, and a copy of Haynes Diesel Engine Repair Manual, undertaking a 6.2L rebuild for the first time would have been a lot more "interesting." The Diesel Page manual is a must-read before you undertake a 6.2L rebuild. Of course, if the engine you plan on giving new life to is an '82-'88, and it's still running, stay the course and rebuild it back to stock; the 25 extra ponies and 45 lb-ft of additional torque gained from the later-model, naturally-aspirated 6.2L might not be worth the time or cost needed to make the upgrade.

Rebuilding For Power

Rebuilding the 6.2L diesel is a comparatively cheap way to have reliable and capable diesel power. Instead of paying $6,500 for a crate 6.5L short-block, you can rebuild a 6.2L and kit it with a Banks turbo for about $4,500. As a note of interest, back in 1989, GM chose Banks as the 6.2L dealer-installed turbo option, and remained so until GM released its own 6.5L turbodiesel. This ultimate upgrade for the venerable 6.2L workhorses provides as much as 60-plus hp and 115-plus lb-ft of torque, plus 10 percent better fuel economy according to Banks.

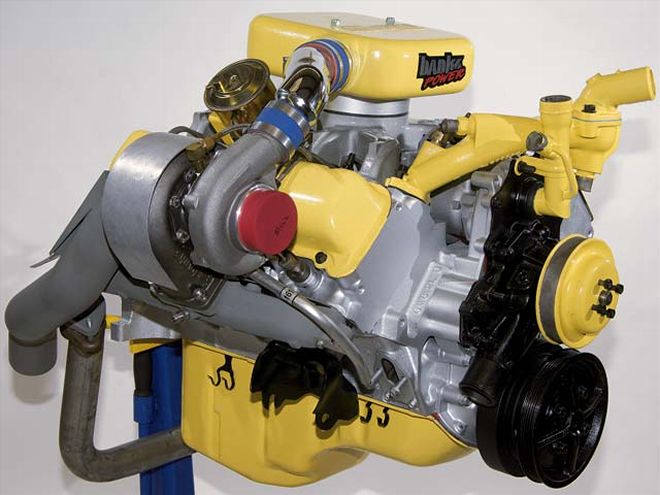

Of course, we wanted everything we could get out of the ancient '82 we bought. That meant a lot of new parts and special attention to details to give it new life. In addition to the typical engine rebuild parts, we stepped up the power quotient on our builder by installing a Banks Sidewinder turbo kit-a dealer option GM offered in the latter days of the 6.2L. The $2,100 Banks kit includes everything from the Banks Ram-Air intake with cast air-filter housing to the Sidewinder turbo with turbocharger exhaust manifold, pressure-chamber-plenum boost tube, special radiator hose, and crankcase-vent duct. It also includes a complete 3-inch stainless exhaust system with a Dynaflow muffler.

Speaking of the power from a rebuilt 6.2L, we ran our "new" Banks' turbo'd engine on the dyno at Vanderley Racing Engines in Lyman, Mississippi, not far from where Karl Hagar and Warren Spears did the overhaul. Here's what we found: The original '82 6.2L delivered 130 hp and 240 lb-ft torque. Our "new" 6.2L delivered 58 hp more than the stock engine did and 110 lb-ft of torque between 1,100 and 1,800 rpm, and 40 hp and 85 lb-ft more power at 2,800. That puts our builder engine in the same power range as the 6.5 turbo found in today's GM heavy-duty pickups.

So, as you can see, the end result of a 6.2L GM rebuild is a stout, reliable, fuel-efficient diesel that runs as good as or better than the popular 6.5L turbodiesel. We expect to get a decade or more of service from this one-and a lot of raised eyebrows when we open the hood to show off how fine a 24-year-old turbodiesel looks. You should see similar results.

| 0554 Dp 62 35 Z

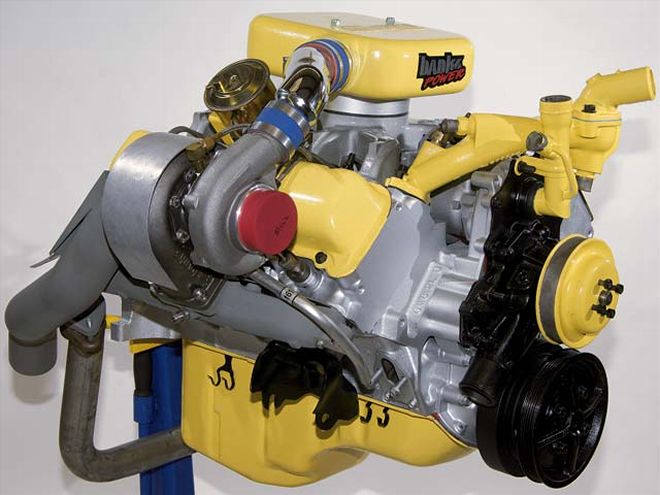

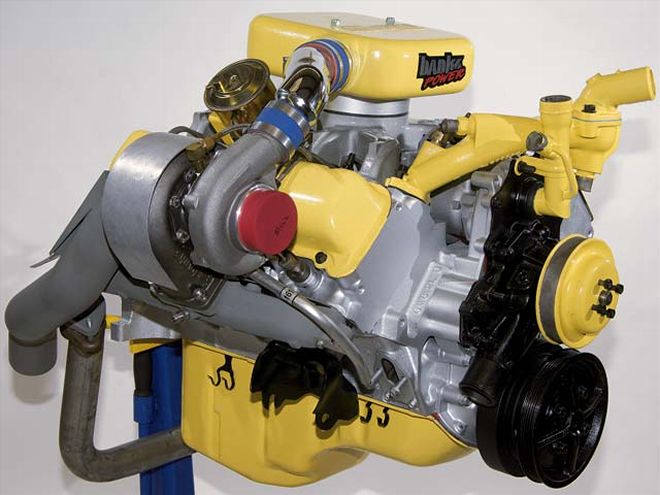

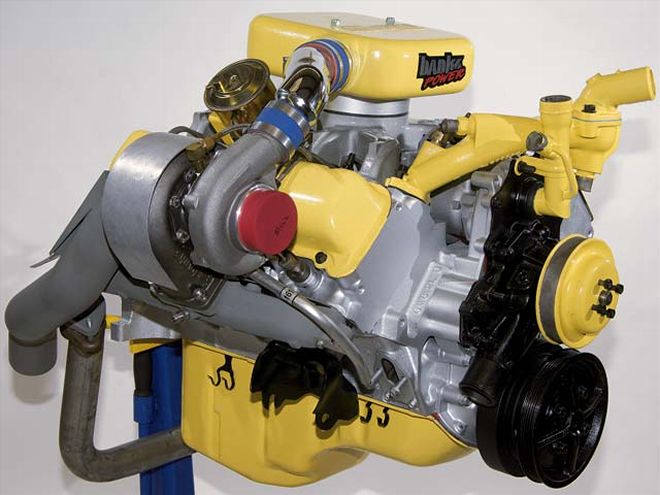

Our rejuvenated "High-Output" 6.2L is ready for the accessories and then off to the dyno. A little powdercoating for color gives the new engine just the right look to go with its performance gained from the rebuild and addition of the Banks Sidewinder turbo kit.

| 0554 Dp 62 35 Z

They are plentiful, they are durable, and they are cheap. In addition, they're simple and economical. Those five factors are what make the venerable 6.2L Chevrolet diesel a very popular builder these days, especially if you are planning on plopping one under the hood of an older 1/2-ton pickup or SUV in place of a gas V-8. The engines were a mainstay in the '82-'93 GM light-duty truck line under the hoods of Chevrolet and GMC pickups, Suburbans, and fullsize vans. The 6.2L was replaced in 1994 by the 6.5L, which was subsequently replaced by the Duramax 6600 in 2001.

| 0554 Dp 62 35 Z

They are plentiful, they are durable, and they are cheap. In addition, they're simple and economical. Those five factors are what make the venerable 6.2L Chevrolet diesel a very popular builder these days, especially if you are planning on plopping one under the hood of an older 1/2-ton pickup or SUV in place of a gas V-8. The engines were a mainstay in the '82-'93 GM light-duty truck line under the hoods of Chevrolet and GMC pickups, Suburbans, and fullsize vans. The 6.2L was replaced in 1994 by the 6.5L, which was subsequently replaced by the Duramax 6600 in 2001.

| This is the '82 C1500 that donated its 6.2L to our cause. The engine wasn't running because the owner had melted off the glow plug's tips and couldn't figure out how to remove them without removing the heads. The engine had less than 200,000 miles on it. We bought the whole truck for $500.

| This is the '82 C1500 that donated its 6.2L to our cause. The engine wasn't running because the owner had melted off the glow plug's tips and couldn't figure out how to remove them without removing the heads. The engine had less than 200,000 miles on it. We bought the whole truck for $500.

| 0554 Dp 62 35 Z

Our rejuvenated "High-Output" 6.2L is ready for the accessories and then off to the dyno. A little powdercoating for color gives the new engine just the right look to go with its performance gained from the rebuild and addition of the Banks Sidewinder turbo kit.

| 0554 Dp 62 35 Z

Our rejuvenated "High-Output" 6.2L is ready for the accessories and then off to the dyno. A little powdercoating for color gives the new engine just the right look to go with its performance gained from the rebuild and addition of the Banks Sidewinder turbo kit.