When looking for increased power, look no further than Gale Banks Engineering, one of the industry's leaders and innovators. Banks opened his shop in 1958, specializing in race engines, and then in 1960, he expanded into the marine performance world. Since those early days, Banks has established himself as an icon, both in the shop and on the track, capturing many land speed records. Known as the master of turbochargers, Banks' technology has contributed to the progression of power enhancement products for the past four decades.

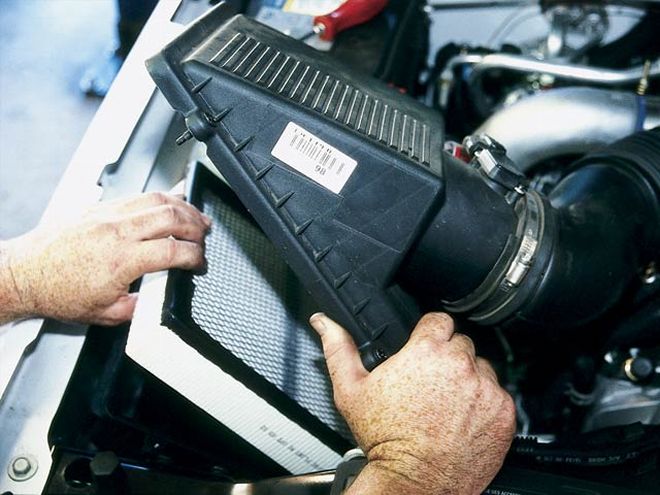

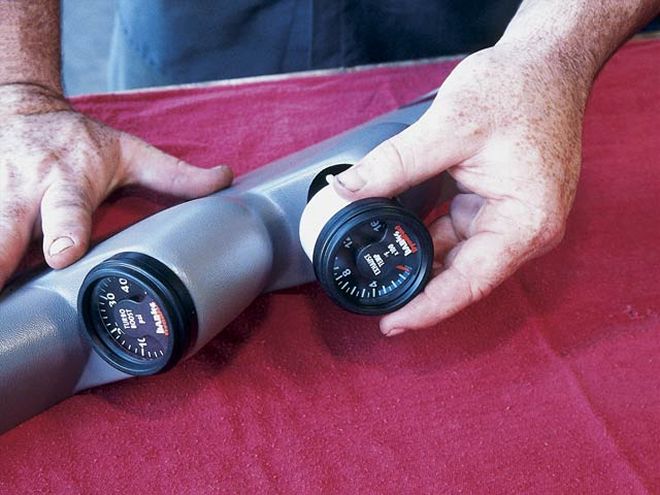

To produce more horsepower from a diesel engine, it's all about volumes of compressed air. More compressed air means more fuel, which creates a greater explosion in the combustion chamber and cylinder. Installing a Banks Power Stinger TLC System on an '00-'04 Chevrolet Duramax 6.6L will increase the airflow to balance the fuel flow. Increasing airflow and fuel flow creates more torque and horsepower.

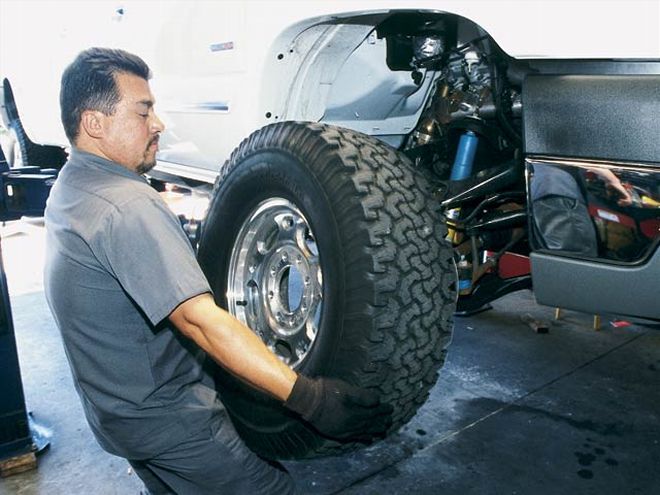

The talented team, headed up by owner Mario Romero, at Top Line Performance in Huntington Beach, California, has been installing suspension and engine performance products and fabricating custom components for its customers for the past eight years. Mario and his talented team installed a Banks Power Stinger TLC System on an '03 Chevrolet 6.6L Duramax turbodiesel pickup. With a fist full of film and the camera already loaded, we followed along as the Banks Stinger TLC System was being installed.

ABCs of a Turbodiesel

A diesel engine, just as a gasoline engine, is considered a mechanical air pump. The amount of air and its velocity inhaled and exhaled affects its performance. The easier the air flows through an engine during its intake, compression, combustion, and exhaust cycles, the greater it will perform. Increasing more air volume and its velocity will create greater torque and increased horsepower. A normal diesel engine's compression ratio is 14:1 to 25:1, which is much higher than a gasoline engine's 8.5:1 to 13:1. A diesel engine takes in air, compresses it, then injects fuel into the compressed air. By compressing the air molecules, it creates heat, and the more they are compressed, the greater the heat. The hot compressed air spontaneously ignites itself.

Installing a turbocharger allows the engine to burn more fuel and air, and by increasing the air compression, it creates hotter temperatures, producing a greater explosion inside the combustion chamber and cylinder, therefore making more torque and horsepower. A turbocharger uses the velocity of the exhaust flow from the engine to spin the turbine located inside the turbocharger housing. The turbine spins an air pump as high as 150,000 rpm, and the hot temperatures of the exhaust flow create very high temperatures inside the turbine due to the intensified compression of hot exhaust gases. Because the turbine is located in the exhaust flow, it restricts the flow.

The effects of the exhaust stroke of the engine makes it push against the higher backpressure of the exhaust (like having to swim upstream), which draws some amount of power. The turbocharger's wastegate helps reduce turbo lag, while at the same time preventing the turbocharger from spinning too quickly at high engine speeds. The wastegate is actually a purge valve that allows the exhaust to bypass the turbine blades by sensing the boost pressure. When the boost pressure gets too high, it is indicating the turbine is spinning too fast, activating the wastegate, bypassing some of the exhaust around the turbine blades, which in turn allows the blades to slow down.

The exhaust is just as important as the intake side of the system. If the exhaust flow is restricted or has too much free-flow, it will affect the engine's performance. The engine's intake and exhaust must be balanced. Factory mufflers are restrictive to help eliminate emissions. The larger diameter aftermarket exhaust systems are designed to eliminate emissions without restricting the exhaust flow and velocity, creating more torque and horsepower.