| 949 Horsepower generation Vi

This month, we bring our GM Performance Parts ZZ502 crate motor buildup to a close, with one last, final run at the dyno that ends with blistering performance, jaw-dropping dyno numbers, and a high-five to engine-builder Steve Brul. The first two installments of this series shed light on the easy-to-install bolt-on parts, which took us from a mild-mannered but healthy 530hp engine to a king-for-a-day-status 740hp brute. These numbers are nothing to sneeze at, and for a motor that can be built in a weekend for less than $12,000 and still run on 91-octane fuel, we feel that this combo was worth every penny. But we're horsepower junkies, and you know what that means: We can't leave well enough alone when we know that there is more power to be made, more bling-bling to be applied, and more fun to be had. With this "more power equals more fun" mantra ringing in our ears, we tore apart our perfectly good motor in preparation for its rebirth.

After the beast was in pieces, we ventured just a few miles south of Westech Performance Group's facility to see Ray Field, owner of Dougan's Racing Engines. Dougan's is a well-known and respected machine shop and engine-building facility that has performed surgery on a plethora of Gen. VI GM engines, so we felt confident it could help us out in short order.

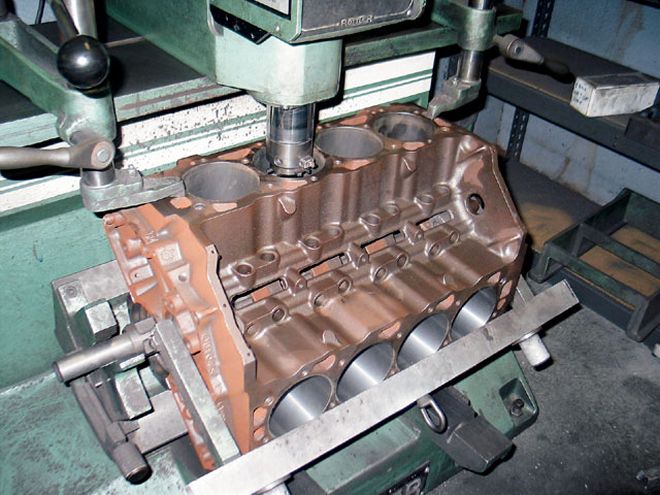

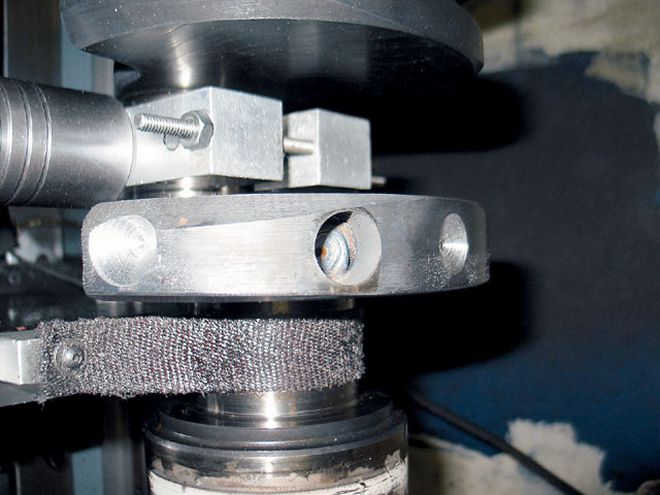

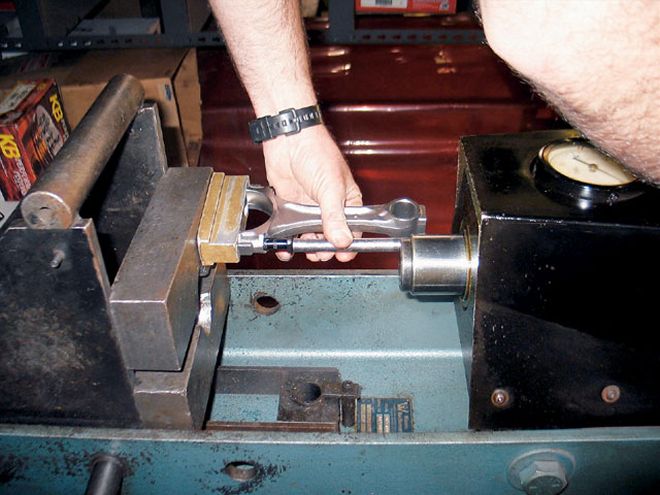

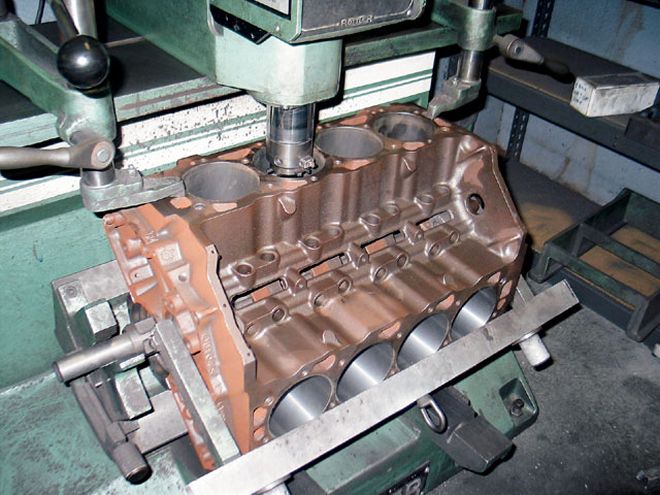

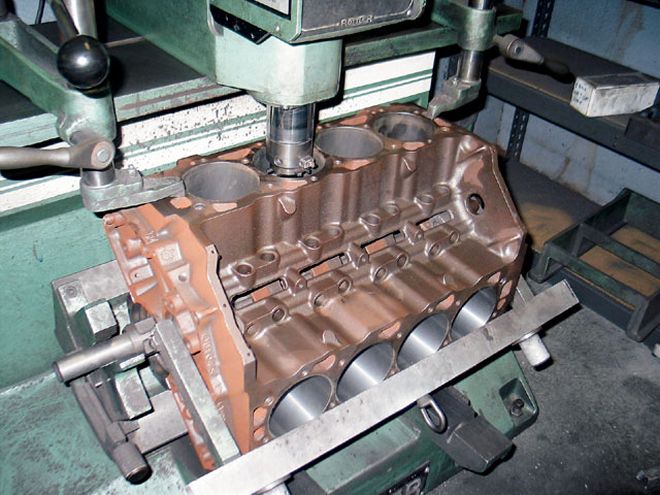

The crew at Dougan's machined our engine block, opening up the bore size from 4.47 inches to 4.50 inches in preparation for a new set of JE blower pistons. We reused the 4-inch-stroke forged GMPP crankshaft after it received a complete balance and micropolish. We also reused the forged GMPP connecting rods after they were resized and fitted with 7/16-inch ARP bolts. The entire rotating assembly was also balanced and blueprinted.

The long-block was once again made complete with our Air Flow Research 315 CNC'd cylinder heads and a blower-specific grind camshaft from Comp Cams. To feed the hungry machine, we picked out a set of 950-cfm Holley HP-series carburetors, which were promptly bolted onto an 8-71 Weiand street supercharger.

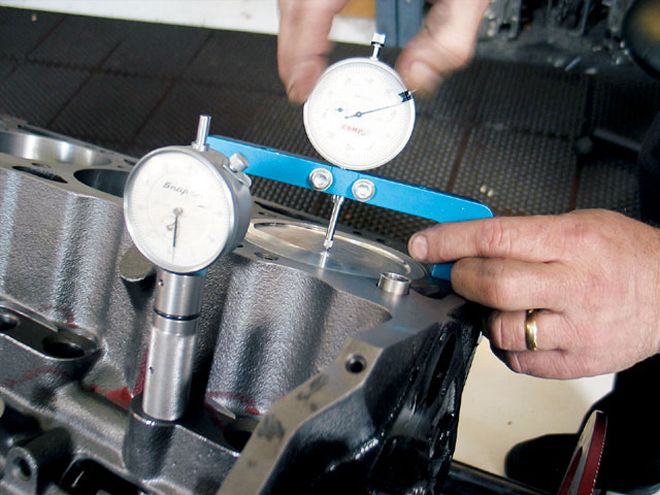

Steve Brul, resident dyno king at Westech Performance Group, cleaned, measured, and assembled our new parts. He also lent his expert hand at tuning the engine once it was strapped onto the Superflow dyno so that we could squeeze every last ounce of power out of the engine on 91-octane fuel.

For more information on any of the parts used in this article, please contact the companies listed in the source box.

Performance TestingThe remaining parts of this power equation included a reinstallation of the MSD 6AL ignition system, Moroso 10-quart oil pan, electric water pump, and exhaust system. The engine exhaled through headers with 2-1/4-inch primary tubes and 3-inch collectors, with mufflers. Timing was locked in at 32 degrees advanced, and the valve lash was set at 0.016 inch. The carburetors were jetted with #83 jets for the primary fuel circuits and #90 jets for the secondary circuits. The boost reference circuits were also coupled to the intake manifold. The oil pan was also filled with 10W30 weight Royal Purple synthetic motor oil after the initial break-in run on the dyno. Because of the small combustion chamber size of our milled AFR cylinder heads, the static compression ratio of this engine with the dished JE blower pistons ended up being 8.71:1, a figure that seems a bit high for a blower engine. We were confident that the engine would live on pump gasoline as long as it ran cool. Just to be sure, though, the engine was fed a diet of 100-octane race fuel during break-in to ensure that detonation would not be a problem, and 91-octane fuel during dyno testing, once we were sure the engine was happy with 32 degrees of ignition timing.

We are happy to report that this engine runs great on 91-octane and performed better than we'd anticipated. Off-idle torque is tremendous, and according to Westech's Superflow dyno, this engine builds more than 721 lb-ft torque at just 3,500 rpm and peaks at 5,000 rpm with 812 lb-ft. If you're looking for an engine that'll get your project truck moving up any mountain or any rock face, or tow anything the rest of the drivetrain is up to moving, this is it. Of course, with all that torque being produced, the horsepower number is huge as well. Peak horsepower was registered at 6,500 rpm, but, honestly, the engine would have made more had we had the nerve to push it a few hundred more rpms. We wimped out at 6,500 as the dyno spit out a 949hp testament to the excellent performance of these parts. To top it all off, we have all that power and an engine that will still idle at 900 rpm, with the occasional blower surge to 1,800 rpm.

THE NUMBERS RPM TORQUE HORSEPOWER 3,000 689.6 394.1 3,500 721.1 481.0 4,000 713.4 581.6 4,500 808.3 693.1 5,000 812.0 773.2 5,500 800.7 839.0 6,000 782.9 894.9 6,500 766.7 949.9 Peak Torque: 812.1@5.100 rpm

Peak Horsepower: 949.9@6.500 rpm

| 949 Horsepower generation Vi

This month, we bring our GM Performance Parts ZZ502 crate motor buildup to a close, with one last, final run at the dyno that ends with blistering performance, jaw-dropping dyno numbers, and a high-five to engine-builder Steve Brul. The first two installments of this series shed light on the easy-to-install bolt-on parts, which took us from a mild-mannered but healthy 530hp engine to a king-for-a-day-status 740hp brute. These numbers are nothing to sneeze at, and for a motor that can be built in a weekend for less than $12,000 and still run on 91-octane fuel, we feel that this combo was worth every penny. But we're horsepower junkies, and you know what that means: We can't leave well enough alone when we know that there is more power to be made, more bling-bling to be applied, and more fun to be had. With this "more power equals more fun" mantra ringing in our ears, we tore apart our perfectly good motor in preparation for its rebirth.

After the beast was in pieces, we ventured just a few miles south of Westech Performance Group's facility to see Ray Field, owner of Dougan's Racing Engines. Dougan's is a well-known and respected machine shop and engine-building facility that has performed surgery on a plethora of Gen. VI GM engines, so we felt confident it could help us out in short order.

The crew at Dougan's machined our engine block, opening up the bore size from 4.47 inches to 4.50 inches in preparation for a new set of JE blower pistons. We reused the 4-inch-stroke forged GMPP crankshaft after it received a complete balance and micropolish. We also reused the forged GMPP connecting rods after they were resized and fitted with 7/16-inch ARP bolts. The entire rotating assembly was also balanced and blueprinted.

The long-block was once again made complete with our Air Flow Research 315 CNC'd cylinder heads and a blower-specific grind camshaft from Comp Cams. To feed the hungry machine, we picked out a set of 950-cfm Holley HP-series carburetors, which were promptly bolted onto an 8-71 Weiand street supercharger.

Steve Brul, resident dyno king at Westech Performance Group, cleaned, measured, and assembled our new parts. He also lent his expert hand at tuning the engine once it was strapped onto the Superflow dyno so that we could squeeze every last ounce of power out of the engine on 91-octane fuel.

For more information on any of the parts used in this article, please contact the companies listed in the source box.

| 949 Horsepower generation Vi

This month, we bring our GM Performance Parts ZZ502 crate motor buildup to a close, with one last, final run at the dyno that ends with blistering performance, jaw-dropping dyno numbers, and a high-five to engine-builder Steve Brul. The first two installments of this series shed light on the easy-to-install bolt-on parts, which took us from a mild-mannered but healthy 530hp engine to a king-for-a-day-status 740hp brute. These numbers are nothing to sneeze at, and for a motor that can be built in a weekend for less than $12,000 and still run on 91-octane fuel, we feel that this combo was worth every penny. But we're horsepower junkies, and you know what that means: We can't leave well enough alone when we know that there is more power to be made, more bling-bling to be applied, and more fun to be had. With this "more power equals more fun" mantra ringing in our ears, we tore apart our perfectly good motor in preparation for its rebirth.

After the beast was in pieces, we ventured just a few miles south of Westech Performance Group's facility to see Ray Field, owner of Dougan's Racing Engines. Dougan's is a well-known and respected machine shop and engine-building facility that has performed surgery on a plethora of Gen. VI GM engines, so we felt confident it could help us out in short order.

The crew at Dougan's machined our engine block, opening up the bore size from 4.47 inches to 4.50 inches in preparation for a new set of JE blower pistons. We reused the 4-inch-stroke forged GMPP crankshaft after it received a complete balance and micropolish. We also reused the forged GMPP connecting rods after they were resized and fitted with 7/16-inch ARP bolts. The entire rotating assembly was also balanced and blueprinted.

The long-block was once again made complete with our Air Flow Research 315 CNC'd cylinder heads and a blower-specific grind camshaft from Comp Cams. To feed the hungry machine, we picked out a set of 950-cfm Holley HP-series carburetors, which were promptly bolted onto an 8-71 Weiand street supercharger.

Steve Brul, resident dyno king at Westech Performance Group, cleaned, measured, and assembled our new parts. He also lent his expert hand at tuning the engine once it was strapped onto the Superflow dyno so that we could squeeze every last ounce of power out of the engine on 91-octane fuel.

For more information on any of the parts used in this article, please contact the companies listed in the source box.