| chevy Engine gorilla Motor

In the first installment (April '04) of Sport Truck's 502-cid crate-motor buildup series, we gathered baseline dyno numbers on our test mule's big-block Chevy at Westech Performance Group in Mira Loma, California. After a few good pulls of the stock GM Performance Parts ZZ502 mill, we added some easy-to-install parts from MSD, Comp Cams, Edelbrock, and Demon Carburetion. These upgrades gave the engine a 37hp, 54-lb-ft-of-torque shot in the arm to further this engine's performance. Those upgrades were mild to say the least, using off-the-shelf parts that most readers could install at home. This time around, we're stepping up our program and moving toward our ultimate goal of building a powerhouse big-block Chevy engine that'll run on today's available pump gas.

| chevy Engine the Parts

The PartsPower is all about airflow. Packing as much air into the engine's combustion chambers as possible, adding a dose of fuel, and throwing a spark on it is the recipe for a big bang and big power. The limiting factor of most engines, and especially our crate motor, is the flow characteristics of the cylinder heads. Now, we could've taken the factory GM Performance Parts heads to a cylinder-head-porting specialist and spent a large chunk of time and money in making them perform better, but we chose an easier route. We called Air Flow Research because it recently developed a completely new line of high-performance aluminum cylinder heads that outflow our current heads. Tony Mamo, head of Product Design for AFR, recommended 315cc CNC-ported Magnum cylinder heads.

The Magnum heads represent a giant leap in cylinder-head design and technology. The heads are available in sizes ranging from 305cc to the big-daddy 357cc CNC-ported behemoths, depending on which CNC program you choose. All the heads feature Tony's unique "heart-shaped" combustion-chamber design, with the differences between them being port size, runner volume, and valve diameter. The combustion chamber's unique shape is Tony's answer to unshrouding the valves for increased airflow; they are available in 119cc and 121cc volumes as cast or CNC-finished versions. The valve placement in the head differs from factory designs because AFR has rolled the valve angles 2 degrees toward the port openings to improve the angle of flow from the valve to the port. Because of the nontraditional valve angle, standard stud girdles won't work on these heads; however, AFR will have its own line available in the future. One great feature that all the heads share is the standard 0.750-inch-thick head deck, which enables these heads to be angle- or flat-milled and still retain their integrity while closing the chamber volumes to as small as 110 cc.

| chevy Engine combustion Chambers

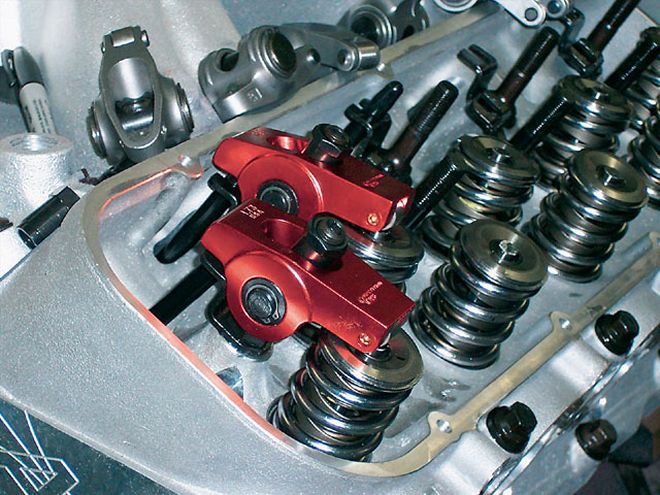

The basic package includes a competition five-angle valve job, stainless-steel 2.25-inch intake valves, and 1.88-inch exhaust valves. Roller dual-valve springs are standard and will provide 240 pounds of spring pressure on the seat. They're good for as much as 0.750 inches of lift. Chrome-moly retainers, valve locks, and seals are included, as are hardened shims and valve seats. The heads are also fit with bronze valve guides, 7/16-inch rocker studs and guideplates, and all standard accessory holes are predrilled and tapped.

When ordering a set of Magnum heads, you'll have many options to choose from to build the perfect head for your application. Valves are available in both stainless-steel and titanium materials, in sizes ranging from 1.60 to 2.30 inches. According to Tony, "These heads are perfect for a nitrous or blower motor that'll generate high cylinder pressures." It's a strong head indeed, and we plan to take full advantage of these flexible performing heads later on.

Our particular heads were flat-milled to mimic the original GMPP head's 110cc chamber volume and retain the original 9.6:1 compression ratio of the engine. Our heads were also outfitted with AFR's tulip-shaped valves (a $40 upgrade), which are good for an additional 10-15 cfm of airflow, depending on where the lift is measured. On smaller-displacement applications, AFR recommends maintaining an intake/ exhaust ratio of 70-80 percent to prevent overscavenging the engine. The techs at AFR will help you choose the proper port volume, combustion-chamber size, and valve diameter.

The PayoffTo say that this motor is impressive would be the understatement of the year. We were literally blown away at this mill's ability to produce gobs of power on 91-octane fuel. With a compression ratio of just 9.75:1 and off-the-shelf parts that can easily be installed by nearly any home mechanic, this engine is a forgiving recipe that will definitely haul the mail in your pickup. Dyno-testing showed that this engine continuously made more than 700 hp all day long and had several peak runs reaching near 740 hp. The really impressive spec, though, is this motor's extremely flat torque curve. From 4,000 to 6,400 rpm, the engine never made less than 612 lb-ft of torque.

DYNO INFORMATION 502-CID BBC RPM POWER TORQUE 4,000 467.0 612.7 4,500 565.0 658.9 5,000 636.0 666.7 5,500 687.0 656.2 6,000 727.0 636.8 6,500 738.1 596.4

Max power = 739 at 6,400 rpm

Max torque = 669.9 at 4,700 rpm

| chevy Engine gorilla Motor

In the first installment (April '04) of Sport Truck's 502-cid crate-motor buildup series, we gathered baseline dyno numbers on our test mule's big-block Chevy at Westech Performance Group in Mira Loma, California. After a few good pulls of the stock GM Performance Parts ZZ502 mill, we added some easy-to-install parts from MSD, Comp Cams, Edelbrock, and Demon Carburetion. These upgrades gave the engine a 37hp, 54-lb-ft-of-torque shot in the arm to further this engine's performance. Those upgrades were mild to say the least, using off-the-shelf parts that most readers could install at home. This time around, we're stepping up our program and moving toward our ultimate goal of building a powerhouse big-block Chevy engine that'll run on today's available pump gas.

| chevy Engine gorilla Motor

In the first installment (April '04) of Sport Truck's 502-cid crate-motor buildup series, we gathered baseline dyno numbers on our test mule's big-block Chevy at Westech Performance Group in Mira Loma, California. After a few good pulls of the stock GM Performance Parts ZZ502 mill, we added some easy-to-install parts from MSD, Comp Cams, Edelbrock, and Demon Carburetion. These upgrades gave the engine a 37hp, 54-lb-ft-of-torque shot in the arm to further this engine's performance. Those upgrades were mild to say the least, using off-the-shelf parts that most readers could install at home. This time around, we're stepping up our program and moving toward our ultimate goal of building a powerhouse big-block Chevy engine that'll run on today's available pump gas.

| chevy Engine the Parts

The Parts

| chevy Engine the Parts

The Parts | chevy Engine combustion Chambers

The basic package includes a competition five-angle valve job, stainless-steel 2.25-inch intake valves, and 1.88-inch exhaust valves. Roller dual-valve springs are standard and will provide 240 pounds of spring pressure on the seat. They're good for as much as 0.750 inches of lift. Chrome-moly retainers, valve locks, and seals are included, as are hardened shims and valve seats. The heads are also fit with bronze valve guides, 7/16-inch rocker studs and guideplates, and all standard accessory holes are predrilled and tapped.

When ordering a set of Magnum heads, you'll have many options to choose from to build the perfect head for your application. Valves are available in both stainless-steel and titanium materials, in sizes ranging from 1.60 to 2.30 inches. According to Tony, "These heads are perfect for a nitrous or blower motor that'll generate high cylinder pressures." It's a strong head indeed, and we plan to take full advantage of these flexible performing heads later on.

Our particular heads were flat-milled to mimic the original GMPP head's 110cc chamber volume and retain the original 9.6:1 compression ratio of the engine. Our heads were also outfitted with AFR's tulip-shaped valves (a $40 upgrade), which are good for an additional 10-15 cfm of airflow, depending on where the lift is measured. On smaller-displacement applications, AFR recommends maintaining an intake/ exhaust ratio of 70-80 percent to prevent overscavenging the engine. The techs at AFR will help you choose the proper port volume, combustion-chamber size, and valve diameter.

| chevy Engine combustion Chambers

The basic package includes a competition five-angle valve job, stainless-steel 2.25-inch intake valves, and 1.88-inch exhaust valves. Roller dual-valve springs are standard and will provide 240 pounds of spring pressure on the seat. They're good for as much as 0.750 inches of lift. Chrome-moly retainers, valve locks, and seals are included, as are hardened shims and valve seats. The heads are also fit with bronze valve guides, 7/16-inch rocker studs and guideplates, and all standard accessory holes are predrilled and tapped.

When ordering a set of Magnum heads, you'll have many options to choose from to build the perfect head for your application. Valves are available in both stainless-steel and titanium materials, in sizes ranging from 1.60 to 2.30 inches. According to Tony, "These heads are perfect for a nitrous or blower motor that'll generate high cylinder pressures." It's a strong head indeed, and we plan to take full advantage of these flexible performing heads later on.

Our particular heads were flat-milled to mimic the original GMPP head's 110cc chamber volume and retain the original 9.6:1 compression ratio of the engine. Our heads were also outfitted with AFR's tulip-shaped valves (a $40 upgrade), which are good for an additional 10-15 cfm of airflow, depending on where the lift is measured. On smaller-displacement applications, AFR recommends maintaining an intake/ exhaust ratio of 70-80 percent to prevent overscavenging the engine. The techs at AFR will help you choose the proper port volume, combustion-chamber size, and valve diameter.