There are times in life when we must endure that which is unpleasant for the greater good of all. And while it may not be high on that list for some, vehicle emissions equipment has certainly become unpleasant for many—especially diesel truck owners. But if we step back and take a moment to understand just how these systems work, we can make living with them a little less painful.

When Tier 2 emissions standards went into effect in 2004, diesel engine manufacturers were tasked with finding a way to lower nitrogen oxide (NOx) output. Their solution was found in the use of exhaust gas recirculation (EGR). The basic function of an EGR system is to route a portion of spent exhaust gases back into the engine's intake tract. This oxygen-deprived air is used to limit peak in-cylinder combustion temperatures, which in turn lowers the engine's NOx production. Before being mixed with the incoming air, the exhaust gases are cooled by passing through an EGR cooler, and then metered through an EGR valve.

Ford was the first to get in the game with the International-built 6.0L Power Stroke, which made its debut in 2003 Ford Super Duty trucks. GM followed by adding EGR to the LLY Duaramax for 2004½. And thanks to accumulated emissions credits, the 5.9L Cummins remained without EGR for its entire run. The 6.7L was the first generation of the inline-six to receive this treatment (starting

in '07½.)

Unfortunately, while good for the environment, the EGR gases from a diesel tend to bring with them a sooty mess. Think of it as cholesterol in your body. The soot, over time, has a tendency to gum up the EGR metering valve, EGR cooler, engine intake ports, and any sensors that are downstream of its injection point—and contaminate the engine's oil. And the dirtier your truck runs, the more quickly these systems become infected. Black smoke might seem cool coming out the tailpipe, but remember it's also flowing through the EGR system.

| Exhaust Gas Recirculation Tech 02

The most notorious engine for EGR failures is the 6.0L Power Stroke. While the root cause of failure is typically a clogged oil cooler starving the EGR cooler of coolant, they can also become clogged by aggressive fueling and poor programming. When looking for a replacement EGR cooler for the 6.0L, remember that the early trucks ('03) had the round-style cooler (left) and '04 to '07 the square style (right.) The earlier, round-style coolers were much less prone to failure.

| Exhaust Gas Recirculation Tech 03

Bullet Proof Diesel in Mesa, Arizona, is best known for fixing EGR cooler issues with the 6.0L Power Stroke. The company takes in failed units from repair shops across the country, guts them, and rebuilds them into more robust coolers by eliminating the problematic stacked-plate design.

| Exhaust Gas Recirculation Tech 04

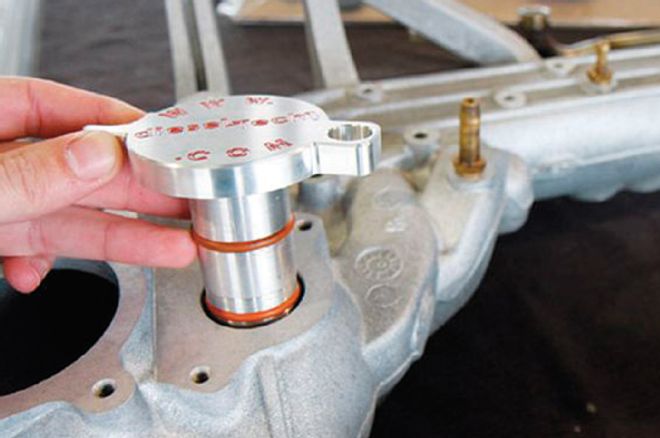

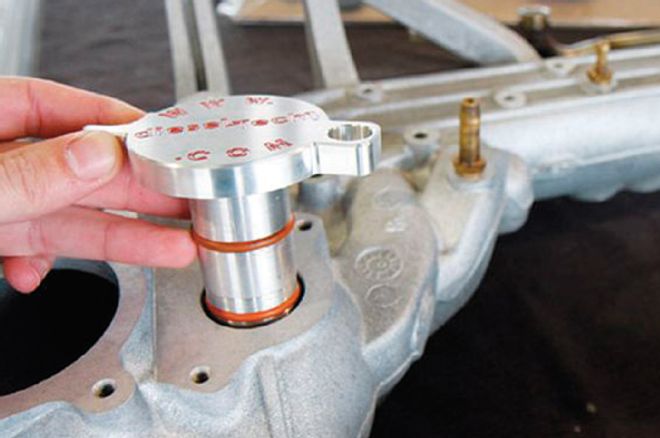

Another option available to competition-only vehicles is a full EGR delete. These come in the form of block-off plates, valve plugs, and bypass kits. While this may solve many of the EGR-related issues, it's worth noting that this is not legal for trucks used on the street and, in most cases, will require a custom tune to eliminate a check engine light. You have been warned.

| Exhaust Gas Recirculation Tech 05

While not as common as the 6.0L, the 6.4L Power Stroke also had an issue with EGR cooler failure. Luckily, the 6.4L's EGR cooler is plumbed in parallel with the cooling system (rather than in series on the 6.0L), which helps to prevent the snowball effect of failures should the EGR cooler become compromised. On the other hand, EGR valve failures are more common with this engine.

| Exhaust Gas Recirculation Tech 06

EGR metering valves tend to take a lot of abuse from being constantly exposed to the exhaust stream. The valve seen on the right is fairly new, while the one on the left is so caked in soot that it has stopped working.

| Exhaust Gas Recirculation Tech 07

The manifold absolute pressure (MAP) sensor all too commonly falls victim to EGR as well. By monitoring pressure changes in the intake tract, the MAP sensor can indicate engine load, boost, operational elevation, and more. Whether you have a Cummins, Duramax, or Power Stroke, cleaning this sensor of EGR-related goop periodically can restore both throttle response and fuel economy.

| Exhaust Gas Recirculation Tech 08

Ford took what seemed like a radical approach to EGR cooling with the 6.7L Power Stroke by employing a massive dual cooler. The EGR comes out of the passenger-side exhaust manifold and is throttled with a hot-side EGR valve before entering the coolers. Gases are then mixed with cool air from the intercooler at the inlet to the upper intake manifold.

| Exhaust Gas Recirculation Tech 02

The most notorious engine for EGR failures is the 6.0L Power Stroke. While the root cause of failure is typically a clogged oil cooler starving the EGR cooler of coolant, they can also become clogged by aggressive fueling and poor programming. When looking for a replacement EGR cooler for the 6.0L, remember that the early trucks ('03) had the round-style cooler (left) and '04 to '07 the square style (right.) The earlier, round-style coolers were much less prone to failure.

| Exhaust Gas Recirculation Tech 02

The most notorious engine for EGR failures is the 6.0L Power Stroke. While the root cause of failure is typically a clogged oil cooler starving the EGR cooler of coolant, they can also become clogged by aggressive fueling and poor programming. When looking for a replacement EGR cooler for the 6.0L, remember that the early trucks ('03) had the round-style cooler (left) and '04 to '07 the square style (right.) The earlier, round-style coolers were much less prone to failure.

| Exhaust Gas Recirculation Tech 03

Bullet Proof Diesel in Mesa, Arizona, is best known for fixing EGR cooler issues with the 6.0L Power Stroke. The company takes in failed units from repair shops across the country, guts them, and rebuilds them into more robust coolers by eliminating the problematic stacked-plate design.

| Exhaust Gas Recirculation Tech 03

Bullet Proof Diesel in Mesa, Arizona, is best known for fixing EGR cooler issues with the 6.0L Power Stroke. The company takes in failed units from repair shops across the country, guts them, and rebuilds them into more robust coolers by eliminating the problematic stacked-plate design.

| Exhaust Gas Recirculation Tech 04

Another option available to competition-only vehicles is a full EGR delete. These come in the form of block-off plates, valve plugs, and bypass kits. While this may solve many of the EGR-related issues, it's worth noting that this is not legal for trucks used on the street and, in most cases, will require a custom tune to eliminate a check engine light. You have been warned.

| Exhaust Gas Recirculation Tech 04

Another option available to competition-only vehicles is a full EGR delete. These come in the form of block-off plates, valve plugs, and bypass kits. While this may solve many of the EGR-related issues, it's worth noting that this is not legal for trucks used on the street and, in most cases, will require a custom tune to eliminate a check engine light. You have been warned.

| Exhaust Gas Recirculation Tech 05

While not as common as the 6.0L, the 6.4L Power Stroke also had an issue with EGR cooler failure. Luckily, the 6.4L's EGR cooler is plumbed in parallel with the cooling system (rather than in series on the 6.0L), which helps to prevent the snowball effect of failures should the EGR cooler become compromised. On the other hand, EGR valve failures are more common with this engine.

| Exhaust Gas Recirculation Tech 05

While not as common as the 6.0L, the 6.4L Power Stroke also had an issue with EGR cooler failure. Luckily, the 6.4L's EGR cooler is plumbed in parallel with the cooling system (rather than in series on the 6.0L), which helps to prevent the snowball effect of failures should the EGR cooler become compromised. On the other hand, EGR valve failures are more common with this engine.

| Exhaust Gas Recirculation Tech 06

EGR metering valves tend to take a lot of abuse from being constantly exposed to the exhaust stream. The valve seen on the right is fairly new, while the one on the left is so caked in soot that it has stopped working.

| Exhaust Gas Recirculation Tech 06

EGR metering valves tend to take a lot of abuse from being constantly exposed to the exhaust stream. The valve seen on the right is fairly new, while the one on the left is so caked in soot that it has stopped working.

| Exhaust Gas Recirculation Tech 07

The manifold absolute pressure (MAP) sensor all too commonly falls victim to EGR as well. By monitoring pressure changes in the intake tract, the MAP sensor can indicate engine load, boost, operational elevation, and more. Whether you have a Cummins, Duramax, or Power Stroke, cleaning this sensor of EGR-related goop periodically can restore both throttle response and fuel economy.

| Exhaust Gas Recirculation Tech 07

The manifold absolute pressure (MAP) sensor all too commonly falls victim to EGR as well. By monitoring pressure changes in the intake tract, the MAP sensor can indicate engine load, boost, operational elevation, and more. Whether you have a Cummins, Duramax, or Power Stroke, cleaning this sensor of EGR-related goop periodically can restore both throttle response and fuel economy.

| Exhaust Gas Recirculation Tech 08

Ford took what seemed like a radical approach to EGR cooling with the 6.7L Power Stroke by employing a massive dual cooler. The EGR comes out of the passenger-side exhaust manifold and is throttled with a hot-side EGR valve before entering the coolers. Gases are then mixed with cool air from the intercooler at the inlet to the upper intake manifold.

| Exhaust Gas Recirculation Tech 08

Ford took what seemed like a radical approach to EGR cooling with the 6.7L Power Stroke by employing a massive dual cooler. The EGR comes out of the passenger-side exhaust manifold and is throttled with a hot-side EGR valve before entering the coolers. Gases are then mixed with cool air from the intercooler at the inlet to the upper intake manifold.