Without turbochargers, modern diesel pickup truck engines would still be back in their anemic 100-something-horsepower days. Sure they could pull out a stump, but good luck with steep hills. Put a trailer behind it, and it got even worse. So, turbos are important, but can you really find an upgrade out of a junkyard? Surprisingly, the answer is a solid yes.

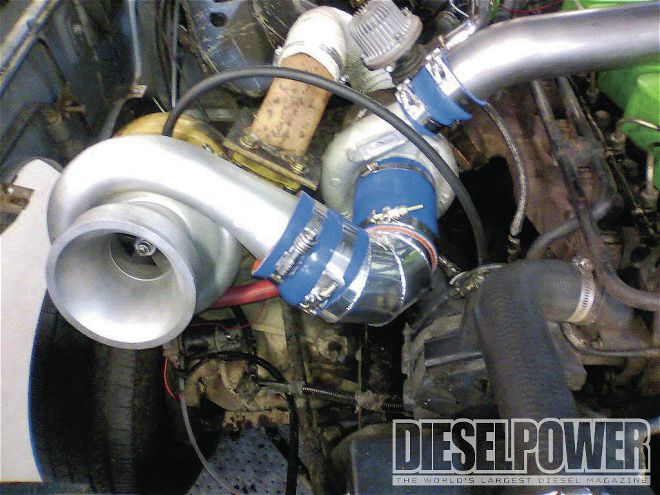

| Rated at only 160 hp at 19 psi in stock form, this VE-pump 5.9L Cummins made 430 rwhp using a junkyard Holset HX52 making 55 psi of boost—for just a few hundred dollars! Notice the exhaust flange adapter and homemade intake used to mount the turbo.

Why Upgrade

“The best turbo setup I could ever make is one that matches the fuel curve exactly,” noted turbo expert Pius Eberle of Bell Turbo. With the Cummins, Power Stroke, and Duramax engines, adding fuel usually comes pretty easy in the form of pump tuning, injectors, or programming (if the engine is computer-controlled). The air side of things, however, is not so simple. Many stock turbochargers are set up to operate in a pre-determined boost range, so if you try to spin them faster, they simply make hot air and won’t flow any more. Even worse, they’ll completely fail. So, when looking at upgrading horsepower—even a few hundred horsepower past stock—a turbocharger upgrade is a must to match the air and fuel curves.

"There are a few 7.3L Power Stroke trucks out there running Holset HX55s or Garrett 4294s, both of which are great-performing turbos on a budget.

— Mike McGlothlin"

Next Year’s Model

One popular way of upgrading a turbo from stock is to simply use the next-generation version. Take Cummins-powered Dodge Ram trucks as an example: Over the years, they used Holset HC1, HX35, HY35, and HE351 turbochargers. As power increased, so did turbocharger size, and as turbos became more advanced and had to perform tasks like exhaust braking, they also became tougher. If you look at a stock HE351 next to an HC1, the difference is obvious. The newer turbo is larger, stronger, and more technically advanced. Often, these compressors can be found on eBay or at a junkyard for a fraction of their retail price.

Junkyard Compressors

“Why can’t I just take a turbo off a big rig or tractor, and put it on my truck?” is a question we get asked all the time. Well, you could, but you might not want to, and we’ll tell you why. Since most industrial equipment (big trucks, tractors, bulldozers) operate under very heavy loads and at low rpm, those turbochargers are sized completely different than turbos for most truck applications. Popular upgrades for daily-driven pickups will have the compressor and exhaust wheels sized similarly, say 62/65/14. This means the turbo has a 62mm-inducer compressor, a 65mm-exducer turbine, and a 14cm2 exhaust housing. In a quick eBay search, we came up with an S2B turbocharger from CAT, which had a 64mm turbine (the right size) but only a 49.5mm compressor wheel. For this reason, the turbo would probably actually flow even less air than a stocker on your truck. Another option we found for cheap ($350) was a Holset HT3B, but at 75/88/27, it was way too big for a pickup truck engine and would take at least 3,000 rpm before it even tried to spool.

| Want to cut the price of your new turbo in half? We installed a High-Tech Turbo 60mm compressor upgrade on a 50mm Holset HC1 and ended up with a 60/60/18 turbo that performed rather well. In our case, excess drive pressure was averted through the use of a large turbine housing.

There are Exceptions

It’s not all doom and gloom on the junkyard side of things, though. There are exceptions. A CAT C7 S200 turbo we found was a 59/60/14, which could work as an upgrade, due to its similarly sized intake and exhaust sides. We also spotted a Holset HX52 that was 66/70/17, which would work well on larger engines, such as the 6.6L Duramax, 6.7L Cummins, or 7.3L Power Stroke. When searching the net or a junkyard for turbochargers, we’d try to limit the spread of the intake and exhaust compressors, with an exhaust housing less than 18cm2.

Packaging Issues

Using a turbocharger on an engine it was never designed for has a specific set of challenges. In almost every application in which a non-stock turbo is used, an adapter flange will be needed on the exhaust side, and the intake piping will need to be re-worked. Since most turbos that offer an increase in performance will be significantly bigger, V-style engines (Power Stroke and Duramax) have the added packaging issues of hood and cowl clearance, as well as much less room for a downpipe. It’s for these reasons that 9 out of 10 budget turbo swaps end up on I-6 Cummins diesels.

| An interesting concept is the remote-mount turbo application. This solves many space and fabrication constraints, but we have yet to see it actually work on a diesel. The truck that’s pictured (which was equipped with a remote-mount) kept blowing turbos due to oiling issues and a lack of drive pressure. This is something we’d like to see further explored by someone with more time than budget.

Diamond in the Rough: The Holset HE351VE

At one time, one of the best budget turbos you could find was the Holset HE351VE variable-geometry turbo. About 3 years ago, these turbos were everywhere, thanks to some bad tuning and vane-sticking problems. Many were replaced rather than taken apart and repaired by dealerships, and the market was flooded with cores that only needed to be cleaned. While the turbo had a unique flange, and the vanes either had to be controlled or locked in a set position, cores could be had for as little as $60. Unfortunately, most of those got snagged up, and prices are closer to $300 now.

| Junkyard Turbos Upgrading On The Cheap Holset He351ve

The Compound Solution

Because of their sizing and the fact that the intake and exhaust piping has to be changed when swapping turbos, using a budget turbo in conjunction with the factory version is a win-win for most enthusiasts. If you are looking for a cheap or junkyard turbo to run as a single charger, expect to modify your engine accordingly and spin the big rpm required to make these turbos work. No matter which route you take (single or compounds), remember to be patient and select the right turbo for the job.