Back in the 1660s, chemist and physicist Robert Boyle discovered the connection between pressure (p), volume (V), and energy (K). He based his theories, which became known as Boyle’s Law, on his own tests and the findings of his contemporary. These involved everything from experiments using 16-horse-power (literally!) to the implementation of an air-filled lamb’s bladder to prove that: pV = K. In turbodiesel terminology, this means the more pressure made—which is created by the turbo compressing an amount of air—will boost its density along with increasing the kinetic energy (which raises the intake temperature).

| Ditching your stock intercooler for an aftermarket upgrade can reduce EGT, increase the longevity of your turbo and engine, improve fuel economy, and even add power.

Wait!!! Don’t Turn the Page Just Yet!

This article isn’t going to be a history lecture—we hope to show you how to get the most power and efficiency out of your engine. It’s important to point out that Boyle published one of the first straightforward explanations about the manipulation of air pressure, which you can use to this day to improve the performance of your turbodiesel. You can always use the link from The Journal of Applied Physiology below if you’d like to take a step back in history and learn the complete origins of pressure laws.

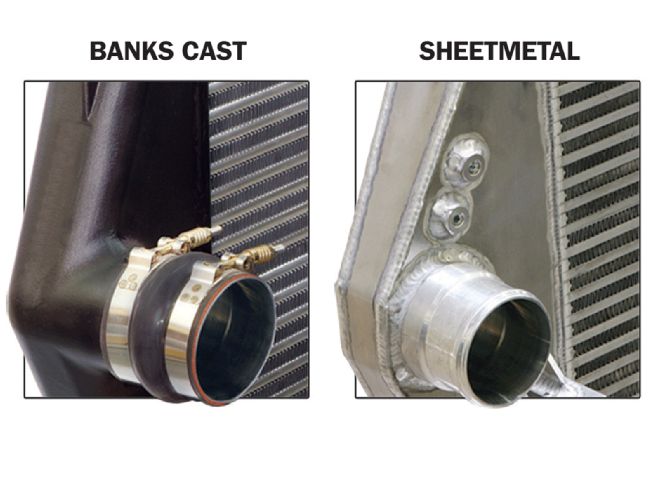

| Aftermarket end cap inlets and outlets provide many advantages compared to stock intercooler designs. Some of these improvements include thicker walls, which reduce the escape or intrusion of heat and provide better (often smoother) flow characteristics.

Modern Turbodiesel Tech

Since Robert Boyle was not available for comment at the time we compiled this article, we contacted Gale Banks, one of the leaders in the field of engineering for modern diesel engines. We asked him about the latest developments with intercoolers to make the turbo flow more efficient, while minimizing the temperature of the intake charge. His company has been tinkering with intercooler designs for decades, and the technicians were happy to provide their findings, which they have used to advance the performance of diesel engines.

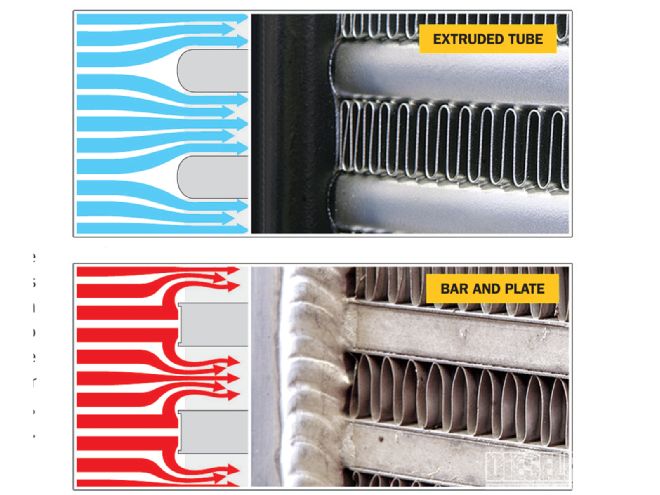

| intercoolers How They Work tank Flow Comparison

Density Does It

Banks wanted to stress that it’s not just airflow, but air density, that’s key to effective intercooling, telling us that “because denser air brings in more oxygen with every stroke, fuel will burn better, or allow for burning more fuel in a given cycle.” Emphasizing what Boyle discovered, Banks said that “with colder air, it becomes possible to get more into a given volume,” so, “an intercooler is essentially a density machine.” With the use of a properly designed intercooler, he noted that, “greater air density means you can add more fuel without increasing exhaust gas temperature or affecting emissions,” and, “more fuel means more power,” or “better mileage, [because] less fuel is needed to make equal power.”

| intercoolers How They Work choked Airflow

The Core Issue

One thing the Banks Power engineers have learned is that extruded-tube intercoolers work better in real-life setups, because space constraints require intercoolers to be placed in front of the engine’s radiator. Bar and plate intercooler cores have been shown to restrict flow through the radiators, which can cause the engine computer to reduce fueling (and performance), due to a lack of cooling. Another element of the intercooler that restricts flow is the cooling fins between the core tubes because of how tightly they are packed. While more fins equals more cooling, it also means less air can flow through for use by the engine and its heat exchangers. As Banks put it, “make the intercooler too efficient, and it ends up being totally selfish, starving the rest of the cooler pack, which needs air, causing those systems to overheat.”

| Improved Outlet Improved Inlet Larger Core Design Core Area: 2.68 inches Thick — 20 Percent Larger than Stock Stock Charge-Air Cooler Outlet Restricted Inlet Restricted Insufficient Core Design Core Area: 2.24 inches Thick — and less overall area Restrictive factory inlets and outlets not only reduce the volume of air allowed to travel throughout the intercooler but can even cause large sections of it to be underutilized, if not completely unused.

Side Jobs

The entry and exit points of the intercooler can make a large difference in performance. While stock intercooler “end tanks” are designed to push air from one side to the other, they don’t always do a great job of routing the air so it can take full advantage of the entire cooling surface area. Banks says his company’s intercoolers use a computer-designed, single-piece, cast-aluminum input and output to avoid the deficiencies of plastic or welded sheetmetal parts, which can restrict flow, melt at high temperatures, or even burst under high pressure. So, make sure you take the construction of these parts into consideration, and don’t forget you’ll also need high-quality tubing and clamps to ensure your turbo charge gets to and from your intercooler. Banks pointed out the real question that needs to be kept in mind: “It may flow better, but does it cool better? You can’t measure that on a flow bench. As a rule of thumb, every 10 degrees you cool the boosted air equals 1 percent more power. So a 250 degree drop has 25 percent more density, or 25 percent more power potential. We measure all this in the truck, on a grade, at full gross, and under full power.”

| While many factory and welded sheetmetal intercooler designs create harsh angles (right), which cause unnecessary turbulence and flow restrictions, a fully cast setup (left) can allow the charged air to move through an upgraded intercooler quickly. This helps it maximize density while retaining pressure, so the engine can optimize its fuel efficiency and power while minimizing EGT.

Lessons Learned

After reading about Boyle’s Law and consulting with Banks, we’ve come away with some basic tips anyone with a turbodiesel can use while shopping for an intercooler upgrade:

- Keep in mind that your goal is to maximize air density— not just a high flow rate.

- Increasing charge density requires surface area, which creates restrictions, but…

- Don’t sacrifice flow-through because other cooling systems need that air, too.

- Construction is key—stock intercoolers and tubing are made for the masses, but you can easily upgrade and improve parts that were originally designed to minimize cost.