Supercharger. Blower. Huffer. There’s just a certain ring to these words. With huge airflow capabilities and a nasty whine, superchargers are a common road to horsepower in the gasoline world, so why not with diesels? Well, a few brave souls have tried blowers, usually in conjunction with nitrous oxide or turbochargers. A lot have failed, but a few setups have worked pretty well. And, in addition to being cool and making power, there are a few other benefits of supercharging, which we’ll gladly explore now.

| Banks Power will soon be unveiling perhaps the most anticipated supercharged diesel ever: a Duramax race engine with a 4.0L supercharger that flows 2,500 cfm. The engine will run the supercharger (there won’t be any turbos) and inject nitrous oxide to make an estimated 1,500 hp.

Why Supercharge? A Broad Power Curve, with Instant Response!

With turbochargers, especially large ones, spool-up time can be two or even three seconds before the turbo is making full boost, and during that spool-up time most diesels are only making about 100 hp. Even with smaller or VGT turbos, the fueling always has to be ahead of the turbo to get it to spool, resulting in black smoke and limited power. Superchargers, on the other hand, will already be up on boost—independent of fueling—and can make as much as 10 psi at idle when mated to a diesel engine. This means there is no turbo lag, only instant response, because there is already enough airflow through the engine to make substantial horsepower.

| “Crazy” Carl of Clarkrange, Tennessee, has been fooling around with supercharging Cummins engines for a while now. In this picture, a turbo is seen blowing through a Whipple supercharger, but Carl found the rotors started flexing above 55 psi of total boost. His current setup draws through the blower, makes 5 psi at idle, and spools the turbo about 500 to 800 rpm sooner than with the turbocharger alone.

Draw-Through, Blow-Through, or Standalone?

Another commonly asked question about superchargers involves their setup and use with turbochargers. We’ve seen three different popular arrangements, including the blower compounding air into the turbocharger, the turbo compounding air into the supercharger, or just running the supercharger by itself. We’ve also seen setups in which the supercharger is only used for low-rpm operation and is then bypassed at higher engine speeds. Most of these arrangements have their merits, although some are definitely better than others.

| The brackets, pulleys, and piping used on Greg’s supercharged Duramax were built by Empire Diesel and featured an F1R Procharger blowing into a GT42-series turbocharger. Throttle response was described as “explosive.”

Blowing into the Supercharger with a Turbo

Detroit Diesel’s two-stroke engines made this setup popular, but it’s also one of the least efficient. Blowers take a lot of power to drive, so putting one downstream of a turbocharger only makes things worse. In addition, most roots or screw superchargers have oiling issues if you try to push more than about 15 psi into them. Centrifugal blowers don’t fare any better, as they will take more power to drive, and the front compressor cover can pop off when pressurized. The only way we would suggest this type of setup is with some type of bypass that circumvents the blower entirely when the turbo is creating boost.

| Unfortunately, shortly after these pictures were taken, the bad, blown Duramax snapped a crankshaft, ending its driving days—at least for now. In Cummins and Power Stroke applications, the stock crankshafts have been holding up from what we’ve seen so far.

Running a Blower as a Single Compressor

Stepping up the ladder a bit in our idea ladder is that of running a supercharger as the only source of compressed air. This isn’t that great of an idea, either, mainly due to the fact that most diesel engines benefit from very high-pressure ratios (lots of boost). Superchargers are very effective in the 5- to 15-psi range, but beyond that they start to sap a lot of power. A large centrifugal supercharger operating at 50 psi might take upward of 500 hp to drive! A turbo of the same size would take about 100 hp at the most, so it’s clear who the winner is. The only way we’d run a supercharger as a single would be in a low boost (less than 30-psi) application with a healthy dose of nitrous oxide to make up the airflow deficit.

| Danny Elmore ran a Procharger on his 6.0L Ford Power Stroke and was one of the few quick 6.0L trucks we’ve seen run smoke free, even on spool-up.

Drawing through a Supercharger with a Turbo

This is an interesting theory and could work well in a few different applications. In this setup, both turbocharger and supercharger are sized very similarly, and the turbocharger sees positive boost from the supercharger at low rpm, and no (or even negative) pressure at higher rpm. Basically, the supercharger is used as a low-end enhancer, but without bypass valves or any other sophisticated hardware. During high-rpm operation, the supercharger is moving enough air so it doesn’t become a restriction or take a lot of power to drive. We believe the aftermarket may soon offer kits with this type of arrangement.

| Perhaps the wildest supercharged diesel we’ve ever seen belonged to Rod Tschiggfrie and featured a massive 9.8L supercharger and two Garrett GT4202 turbochargers. After breaking a stock crank, Rod switched to an internally balanced unit from SoCal Diesel and hasn’t had any issues since.

Blowing into a Turbo with a Supercharger

If you’re going to try a supercharger setup, this is probably the best arrangement one could come up with. This setup works just like a basic compound arrangement, only instead of another turbocharger, the large compressor is a supercharger. This way, the supercharger still makes boost at idle, and as the turbocharger starts making pressure, the strain is taken off the supercharger, which means less horsepower is taken away by driving the blower. For the ultimate in street driveability, a very large centrifugal supercharger could be added to a set of compound turbos, making a three-stage system capable of 2,000 hp in which the blower could be limited to 15 psi or less. This means the big supercharger might only take about 50 to 75 hp to spin—a small price to pay for the response and horsepower potential.

| This killer Duramax was built in Australia and at various times housed supercharged, twin-supercharged, and supercharged and turbocharged Duramax diesel engines.

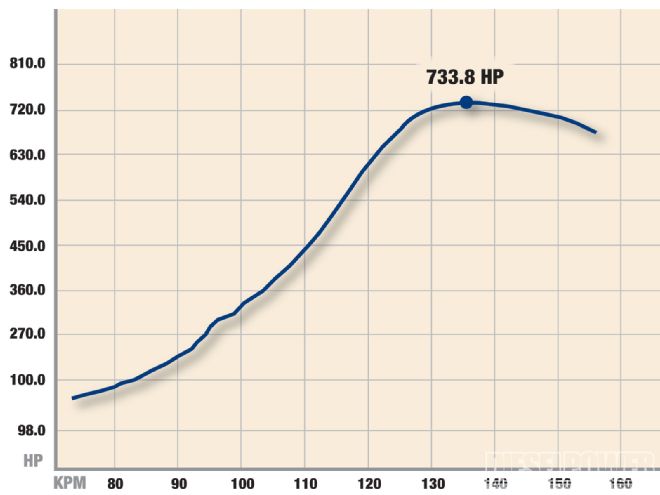

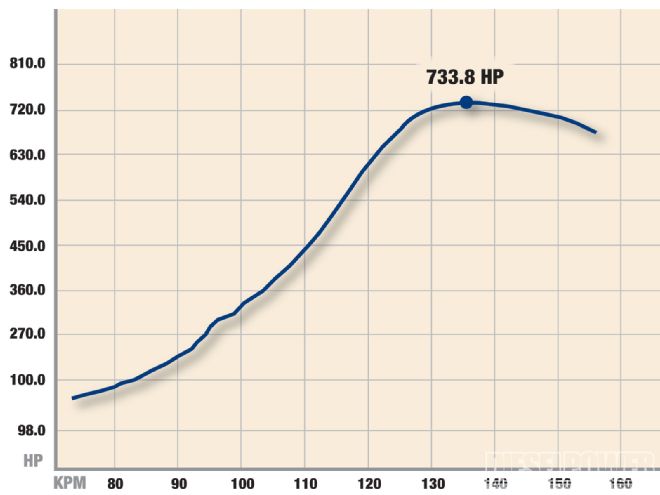

| supercharge Your Diesel dyno Graph

So, Does it Actually Work?

We’ve come to the point in diesel performance where we can definitely say that yes, supercharged diesels can make power. However, driveability is where they really shine, or in very high-horsepower applications in which turbos can take enormous amounts of fuel and rpm to drive. As of right now, the lack of commercially available kits is probably the only reason superchargers haven’t caught on more with diesels, and this is something we hope will change.

| Since 6.2L and 6.5L GM diesels run at relatively low boost levels, they are the perfect diesel to supercharge and can make about 400 hp at the crankshaft with about 20 psi of boost.

How Much Power Does It Take To Drive A Supercharger?

Blower Speed (rpm)

Boost Pressure (psi)

Drive Power Requirement (hp)

36,855

11.7

74.1

38,745

12.2

88

40,635

13.7

118.1

42,525

15.1

127.1

44,415

16.4

140.6

46,305

18.2

156.6

48,195

20

173.4

50,085

21.5

190.5

51,975

23.7

213.4

53,865

25.4

239.2

55,755

27

279.2

57,645

29.1

304.8

59,535

31.3

340.1

61,264

32.9

353.6

If you want to keep drive losses to a minimum in a compound arrangement, keep thepressure ratio of the turbocharger high and the blower boost low. This graph providedby Steve Morris Racing Engines shows how much power it takes to spin a superchargerat high boost levels. The good news is that the 115mm F2 Procharger used to generate this test data is good for between 1,500 and 2,000 hp!

| supercharge Your Diesel dyno Graph

So, Does it Actually Work?

| supercharge Your Diesel dyno Graph

So, Does it Actually Work?