Top Tech Questions - Youve Got Questions? Weve Got Answers!

Welcome to Top Tech Questions. Oftentimes, readers contact us with questions about articles, or to praise us on what a good job we are doing. But our favorite form of reader communication is tech questions. So we're introducing our Top Tech section, a place where you ask what's on your mind, and we answer it. Got a trouble code? Wondering how to get your engine to make more power?

Send us an email at

jason.sands@sorc.com and we'll do our best to answer it.

Question:I have a '93 Dodge 250 with an automatic transmission. I plan on putting 60hp injectors and Rocken-Tech's 14mm head and 4mm cam plate in the injection pump with other add-ons, but I was reading your "First-Gen Performance" article in the Feb. '09 issue, and it says that if I use the Rocken-Tech parts, I need a high-flow lift pump. Problem is, I can't seem to find one for the first-gen Cummins. I would appreciate it if you could help in finding one.

Zach HickmanVia email

| For big horsepower applications, a high-pressure, high-flow lift pump such as this Aeromotive A1000 is highly recommended.

Answer:

There are a few solutions for your lift pump dilemma. First off, the stock lift pump can't support the kind of fuel you will need to be flowing, so don't even try it. There are conversion kits for low-pressure piston-style lift pumps, but we'd stay away from these if you're shooting for more than 400 hp, or running a 14mm head instead of the stock 12mm version. The 14mm/4mm cam plate is probably a combination to stay away from-it seems that the larger pump head combined with more lift is just too taxing on the design of the Bosch VE pump. There was one combination that we're aware of where the 14mm head combined with the big cam plate worked, and the results were impressive: 501 rear-wheel horsepower with a 62mm-inducer turbo. However, this truck only lasted 400 street miles and a few dyno pulls before it ran away on the dyno and the pump seized. So if you're going to try the 14mm/4mm combo, know there are big risks. Instead of 60hp injectors, we'd try to get a set of 6x.016 injectors made for your truck. Places like Scheid Diesel, Buddha Power, and New Era Diesel can custom make injectors that will help just as much as a 14mm head will. With a good size turbo (62 to 64mm-diameter inducer) 450 hp at the wheels is achievable with a 12mm pump, large injectors, and a good fuel system.

A stock Dodge piston lift pump found on '94 to '98 Cummins engines flows about 48 gallons per hour (gph) of fuel at about 15 psi, and first-gen Dodge rotary lift pumps flow even less than that. For a hopped-up VE pump, you're looking for a lift pump that will flow 100 gph or more. While made for gasoline applications, Holley and Carter both make race pumps that will flow in the 120- to 140-gph range and seem compatible in diesel applications. Besides flow, pressure is another thing to worry about. You want at least 10 to 15 psi of pressure to keep the VE pump happy, but no more than about 20 psi or else you are at risk of blowing out the front pump seal and filling the crankcase with diesel. Adding some Loctite to the front pump seal, or making a retainer are fixes for this problem, but at 400 to 500 hp, just make sure you don't exceed 20 psi and you'll probably be fine. In addition to the pump, the stock tank pickup and filter are also restrictions. Bypassing the stock filter and installing a larger version, and installing an aftermarket sump or a draw tube in the fuel tank will take you a long way toward maintaining fuel pressure. If you're looking for an all-in-one solution, a complete fuel system from FASS or AirDog will solve both your filter and pump problems and will be 100 percent compatible with diesel fuel.

With a good turbocharger, you should be making 350 to 400 hp at the wheels at this point, maybe even 450 hp if you have the timing and tune really dialed in. If you decide you still want to step up to the 14mm/4mm combo, then we would suggest an Aeromotive A1000 fuel pump, an AirDog 250, or a FASS 200. Get a fuel pressure gauge and a bypass-style pressure regulator, make sure it never dips below 15 psi, and know that you're on the ragged edge as far as injection pump reliability goes with this combination.

Q: I had some questions about how you would build a drag truck ("The Perfect Diesel"), as seen in the March '09 issue. Why ditch the turbo for a supercharger-especially since you said it would take 200 hp to turn?

Harry WagnerAlbuquerque, New Mexico

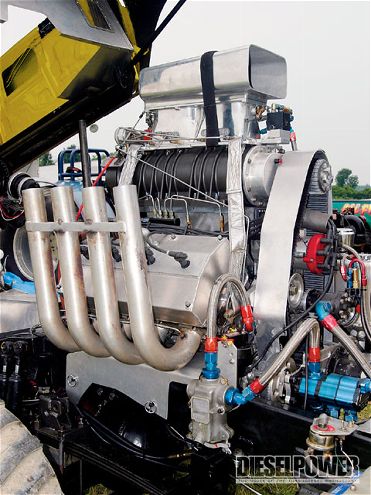

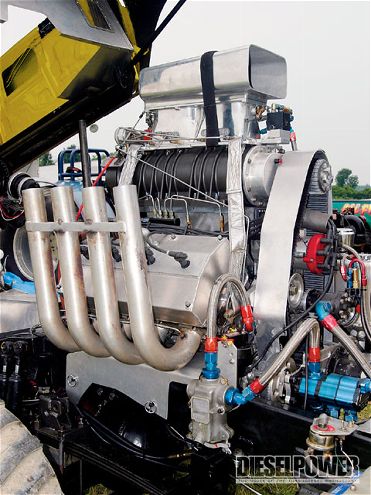

| Although superchargers are common on high-horsepower gasoline and alcohol applications, they've yet to make the jump to the competitive diesel market.

A: We've gotten quite a bit of interest from people wondering about diesel supercharging since we ran that article on how we would build our dream trucks. In our theoretical drag truck buildup, we mentioned we'd use a PSI screw supercharger atop a 6.6L Duramax. While it may sound odd to those familiar with turbochargers, there are several advantages to supercharging.

First and foremost, throttle response would be instant. Since the supercharger would probably be making 5 psi of boost at idle, there would be no time spent spooling turbos. This is particularly favorable in sports like drag racing, where competitors are trying to spool very large turbochargers within a few seconds. With a supercharger, there would be no waiting, just hit the throttle and go!

Another common belief is that superchargers can't move enough air to work well in a diesel application. In Top Alcohol Funny Car racing, enormous screw superchargers are used to generate up to 40 psi of boost on a 500ci (8.0L) engine operating at 8,000 rpm. On a smaller engine that is turning slower (such as a Power Stroke, Cummins, or Duramax) the same blower speed could create even more pressure-something like 70 to 80 psi, which is more than enough to support a high-horsepower diesel engine.

One of the biggest advantages of turbocharging is that it is considered to be free horsepower. Expanding exhaust gases and heat can be used to drive the turbocharger, taking almost no power away from the engine. In fact, using exhaust pressure to spin a turbocharger costs about 1-percent rated power per 10 psi of drive pressure. So in a stock 300hp diesel producing 20 psi of boost pressure (intake side) and 30 psi of drive pressure (exhaust side) the turbo would only be using up 9 hp-pretty close to free power

In diesel racing applications however, turbochargers start to become less efficient. A single turbo on a 1,000hp diesel racing engine may produce 80 psi of drive pressure or more, which means the turbocharger would be taking almost 80 hp to turn. At these power levels, taking 200 hp to drive a supercharger doesn't sound so bad. In our minds, we'd be more than willing to trade 120 hp for instant boost. A supercharger is also less sensitive to camshaft design and head work (which are needed to help large turbos spool) and boost is available over a much broader rpm range, which means more low end torque in high-rpm applications-the best of both worlds.

Q: I have a '00 Volkswagen Jetta TDI. I am just looking to get more power out of it. Do you guys know any way I can make this happen?

Jonathan BrinkVia email

| It's OK if you don't have the new 170hp version of VW's diesel Jetta, the older versions can be upgraded to 200 hp and beyond with a little help from the aftermarket.

A: One of the most common questions we receive from readers is "How do I make more power?" The answer is fairly simple, because no matter what diesel engine you possess, there are a few simple modifications you can perform to increase horsepower and efficiency.

Your first step should be to turn up your injection pump or buy a set of bigger injectors. This will allow more fuel into your engine, giving you more power. If you own a newer diesel, there's probably a computer chip for your ride that can increase timing and injector pulsewidth, which will also give you more fuel. Whether you own an older or newer diesel, this is usually a good point to install gauges, so you can monitor boost and exhaust gas temperatures.

After the fueling is increased, an intake or exhaust should be your next step. Your engine will be making more power, and it may need more air than your stock intake and exhaust system will allow. At this point you may be producing some black smoke, which means it is time for a bigger turbocharger.

Companies like BorgWarner sell turbochargers ranging in size from tiny to humongous, so there will most likely be one that suits your engine. Do some research and find the turbo that is right for you.

If this still isn't enough horsepower, there's always injectables such as propane, water and methanol injection, or nitrous oxide, that will add horsepower to any diesel. Using this basic fuel, air, then power-adder technique, you'll be able to produce enough power that your engine or driveline components will start to fail, so here is where we'll draw the line.

As for your particular vehicle, we'd give Kerma TDI a call at (877) 537-2834, or visit www.kermatdi.com. Kerma has offered injectors, turbo kits, and tuning software for TDI-powered Volkswagens since 2002 and will be able to help you get all the power you can afford out of your '00 VW. DP

| For big horsepower applications, a high-pressure, high-flow lift pump such as this Aeromotive A1000 is highly recommended.

Answer:

| For big horsepower applications, a high-pressure, high-flow lift pump such as this Aeromotive A1000 is highly recommended.

Answer: | Although superchargers are common on high-horsepower gasoline and alcohol applications, they've yet to make the jump to the competitive diesel market.

A: We've gotten quite a bit of interest from people wondering about diesel supercharging since we ran that article on how we would build our dream trucks. In our theoretical drag truck buildup, we mentioned we'd use a PSI screw supercharger atop a 6.6L Duramax. While it may sound odd to those familiar with turbochargers, there are several advantages to supercharging.

First and foremost, throttle response would be instant. Since the supercharger would probably be making 5 psi of boost at idle, there would be no time spent spooling turbos. This is particularly favorable in sports like drag racing, where competitors are trying to spool very large turbochargers within a few seconds. With a supercharger, there would be no waiting, just hit the throttle and go!

Another common belief is that superchargers can't move enough air to work well in a diesel application. In Top Alcohol Funny Car racing, enormous screw superchargers are used to generate up to 40 psi of boost on a 500ci (8.0L) engine operating at 8,000 rpm. On a smaller engine that is turning slower (such as a Power Stroke, Cummins, or Duramax) the same blower speed could create even more pressure-something like 70 to 80 psi, which is more than enough to support a high-horsepower diesel engine.

One of the biggest advantages of turbocharging is that it is considered to be free horsepower. Expanding exhaust gases and heat can be used to drive the turbocharger, taking almost no power away from the engine. In fact, using exhaust pressure to spin a turbocharger costs about 1-percent rated power per 10 psi of drive pressure. So in a stock 300hp diesel producing 20 psi of boost pressure (intake side) and 30 psi of drive pressure (exhaust side) the turbo would only be using up 9 hp-pretty close to free power

In diesel racing applications however, turbochargers start to become less efficient. A single turbo on a 1,000hp diesel racing engine may produce 80 psi of drive pressure or more, which means the turbocharger would be taking almost 80 hp to turn. At these power levels, taking 200 hp to drive a supercharger doesn't sound so bad. In our minds, we'd be more than willing to trade 120 hp for instant boost. A supercharger is also less sensitive to camshaft design and head work (which are needed to help large turbos spool) and boost is available over a much broader rpm range, which means more low end torque in high-rpm applications-the best of both worlds.

Q: I have a '00 Volkswagen Jetta TDI. I am just looking to get more power out of it. Do you guys know any way I can make this happen?

Jonathan Brink

| Although superchargers are common on high-horsepower gasoline and alcohol applications, they've yet to make the jump to the competitive diesel market.

A: We've gotten quite a bit of interest from people wondering about diesel supercharging since we ran that article on how we would build our dream trucks. In our theoretical drag truck buildup, we mentioned we'd use a PSI screw supercharger atop a 6.6L Duramax. While it may sound odd to those familiar with turbochargers, there are several advantages to supercharging.

First and foremost, throttle response would be instant. Since the supercharger would probably be making 5 psi of boost at idle, there would be no time spent spooling turbos. This is particularly favorable in sports like drag racing, where competitors are trying to spool very large turbochargers within a few seconds. With a supercharger, there would be no waiting, just hit the throttle and go!

Another common belief is that superchargers can't move enough air to work well in a diesel application. In Top Alcohol Funny Car racing, enormous screw superchargers are used to generate up to 40 psi of boost on a 500ci (8.0L) engine operating at 8,000 rpm. On a smaller engine that is turning slower (such as a Power Stroke, Cummins, or Duramax) the same blower speed could create even more pressure-something like 70 to 80 psi, which is more than enough to support a high-horsepower diesel engine.

One of the biggest advantages of turbocharging is that it is considered to be free horsepower. Expanding exhaust gases and heat can be used to drive the turbocharger, taking almost no power away from the engine. In fact, using exhaust pressure to spin a turbocharger costs about 1-percent rated power per 10 psi of drive pressure. So in a stock 300hp diesel producing 20 psi of boost pressure (intake side) and 30 psi of drive pressure (exhaust side) the turbo would only be using up 9 hp-pretty close to free power

In diesel racing applications however, turbochargers start to become less efficient. A single turbo on a 1,000hp diesel racing engine may produce 80 psi of drive pressure or more, which means the turbocharger would be taking almost 80 hp to turn. At these power levels, taking 200 hp to drive a supercharger doesn't sound so bad. In our minds, we'd be more than willing to trade 120 hp for instant boost. A supercharger is also less sensitive to camshaft design and head work (which are needed to help large turbos spool) and boost is available over a much broader rpm range, which means more low end torque in high-rpm applications-the best of both worlds.

Q: I have a '00 Volkswagen Jetta TDI. I am just looking to get more power out of it. Do you guys know any way I can make this happen?

Jonathan Brink | It's OK if you don't have the new 170hp version of VW's diesel Jetta, the older versions can be upgraded to 200 hp and beyond with a little help from the aftermarket.

A: One of the most common questions we receive from readers is "How do I make more power?" The answer is fairly simple, because no matter what diesel engine you possess, there are a few simple modifications you can perform to increase horsepower and efficiency.

Your first step should be to turn up your injection pump or buy a set of bigger injectors. This will allow more fuel into your engine, giving you more power. If you own a newer diesel, there's probably a computer chip for your ride that can increase timing and injector pulsewidth, which will also give you more fuel. Whether you own an older or newer diesel, this is usually a good point to install gauges, so you can monitor boost and exhaust gas temperatures.

After the fueling is increased, an intake or exhaust should be your next step. Your engine will be making more power, and it may need more air than your stock intake and exhaust system will allow. At this point you may be producing some black smoke, which means it is time for a bigger turbocharger.

Companies like BorgWarner sell turbochargers ranging in size from tiny to humongous, so there will most likely be one that suits your engine. Do some research and find the turbo that is right for you.

If this still isn't enough horsepower, there's always injectables such as propane, water and methanol injection, or nitrous oxide, that will add horsepower to any diesel. Using this basic fuel, air, then power-adder technique, you'll be able to produce enough power that your engine or driveline components will start to fail, so here is where we'll draw the line.

As for your particular vehicle, we'd give Kerma TDI a call at (877) 537-2834, or visit www.kermatdi.com. Kerma has offered injectors, turbo kits, and tuning software for TDI-powered Volkswagens since 2002 and will be able to help you get all the power you can afford out of your '00 VW. DP

| It's OK if you don't have the new 170hp version of VW's diesel Jetta, the older versions can be upgraded to 200 hp and beyond with a little help from the aftermarket.

A: One of the most common questions we receive from readers is "How do I make more power?" The answer is fairly simple, because no matter what diesel engine you possess, there are a few simple modifications you can perform to increase horsepower and efficiency.

Your first step should be to turn up your injection pump or buy a set of bigger injectors. This will allow more fuel into your engine, giving you more power. If you own a newer diesel, there's probably a computer chip for your ride that can increase timing and injector pulsewidth, which will also give you more fuel. Whether you own an older or newer diesel, this is usually a good point to install gauges, so you can monitor boost and exhaust gas temperatures.

After the fueling is increased, an intake or exhaust should be your next step. Your engine will be making more power, and it may need more air than your stock intake and exhaust system will allow. At this point you may be producing some black smoke, which means it is time for a bigger turbocharger.

Companies like BorgWarner sell turbochargers ranging in size from tiny to humongous, so there will most likely be one that suits your engine. Do some research and find the turbo that is right for you.

If this still isn't enough horsepower, there's always injectables such as propane, water and methanol injection, or nitrous oxide, that will add horsepower to any diesel. Using this basic fuel, air, then power-adder technique, you'll be able to produce enough power that your engine or driveline components will start to fail, so here is where we'll draw the line.

As for your particular vehicle, we'd give Kerma TDI a call at (877) 537-2834, or visit www.kermatdi.com. Kerma has offered injectors, turbo kits, and tuning software for TDI-powered Volkswagens since 2002 and will be able to help you get all the power you can afford out of your '00 VW. DP