| biodiesel Vs Your Warranty machines

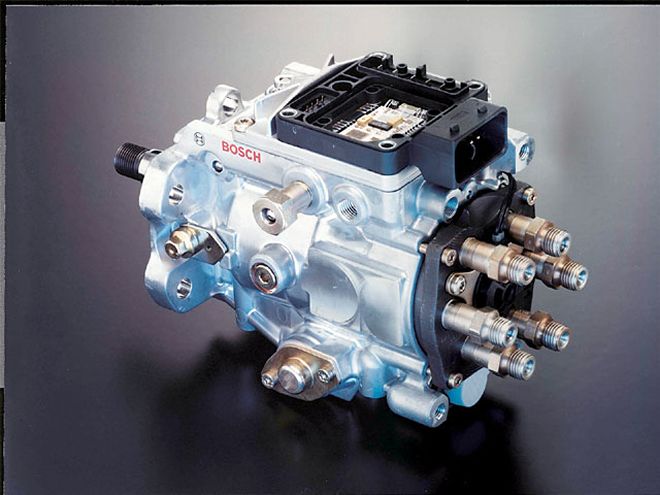

Imagine all the legal issues that can keep automotive manufacturers awake at night. Now, put yourself in the shoes of the companies behind the super-high-pressure diesel injection systems found in millions of cars and trucks. One mistake, and you could face warranty bills from multiple vehicle manufacturers representing hundreds of thousands of drivers (and millions of dollars!).

With that in mind, it's no wonder that biodiesel is being treated with caution by the fuel injection equipment (FIE) manufacturers-aka Bosch, Delphi, Denso, Siemens VDO, and Stanadyne. Although they support the development of alternative (non-petroleum) fuels in diesel engines, they are wary of unregulated biodiesel being used in equipment that was designed to run primarily on highly regulated #2 Diesel.

This is a gray area due to the wide variety of source materials used to make biodiesel, which means there are lots of undesirable finished products that could end up in your fuel tank. This kind of uncertainty can make FIE manufacturers toss and turn in their beds at night worrying about bad stuff roaming through their equipment such as:* Free methanol* Water* Free glycerine* Mono-, di-, and triglycerides* Free fatty acids* Solid particles* Oxidated fuel

So if your truck is under warranty and you want to run biodiesel, you'd better read this official statement by the FIE manufacturers before you fill the tank.

The Manufacturers' PositionDiesel fuel injection equipment manufacturers encourage the development of renewable compression-ignition fuels. Experience to date with rapeseed methyl ester (RME) fuels in Europe suggests that RME conforming to the European standard EN14214 at the point of sale used in mixtures of up to 5 percent by volume with mineral diesel fuel complying with the EN590 diesel fuel standard should not give end users any serious problems.

The currently agreed position of Bosch, Delphi, Denso, Siemens VDO, and Stanadyne is to limit release of injection equipment for mixtures of up to a maximum of 5 percent fatty acid methyl esters (FAME), meeting the EN14214 standard, with unadulterated diesel fuel (meeting the EN590 standard). The final product B5 must also comply with EN590.

-

-

The required quality of FAME (biomass-based) fuel is defined in European standard EN14214, which covers relevant impurities and tramp chemicals from processing. Suppliers of bio fuels must be able to demonstrate compliance to this standard at the filling station. There are several risks associated with possible supply chains.

For the FIE manufacturers, a key property of any bio fuel is resistance to oxidation. Aged or poor-quality bio fuel contains organic acids like formic and acetic acids and acids of higher molecular weight as well as polymerization products that attack many components, drastically reducing the service life of the injection system. A list of issues that have been witnessed in service is detailed in the attachment to this document (chart, page 100).

The ATSM specification for bio fuel (D6751) does not contain a requirement for oxidation stability. The ATSM diesel fuel specification (D975) makes no provision for the inclusion of bio fuel, although there are currently proposals to define a specification for blends up to B20 (20 percent). The FIE manufacturers are concerned both with the missing oxidation stability in the specification and the lack of sufficient safeguards against blend quantity.

The FIE manufacturers can accept no legal liability for failure attributable to operating their products with fuels for which the products were not designed, and no warranties or representations are made as to the possible effects of running these products with such fuels.

Non-compliance of the fuel standards agreed by the FIE manufacturers, whether being evident by appearance of the known degradation products of these fuels or their known effects within the fuel injection equipment (chart, page 100), will render the FIE manufacturers' guarantee null and void.-From the Common Position Statement on FAME Fuels as a Replacement or Extender for Diesel Fuels (June 2004)

There you have it. Without a standard, such as the one used in Europe, running biodiesel could lead to warranty problems. Even when using fuel that meets the European standard, the FIE manufacturers are only comfortable with a mix of 5 percent (B5) biodiesel and 95 percent #2 Diesel-and that's only if the final product meets the same standard required of pump diesel.

Does this mean your common-rail fuel system will seize if you fill it with B100? Nope. But if it does, and your tank is full of unregulated biodiesel, don't expect your warranty to pick up the repair tab.

-

-

Biodiesel Pros and ConsIn addition to petroleum, Diesel fuel can be made from various vegetableoils, including canola and soybean. The ASTM has also released a standard, D-6751, for biodiesel fuels.Stanadyne, as well as the other major fuel injection equipment manufacturers, has determined that a blend of 5 percent biodiesel that meets the ASTM D-6751 standard and 95 percent mineral diesel that meets the ASTM D-975 standard should not harm fuel system components. This blend is referred to as B5. As with ULSD, biodiesel fuel also has various advantages and disadvantages:

Advantages of biodiesel*Reduced exhaust emissions*Made from a renewable resource*Almost no sulfur (in the biodiesel itself)*Higher cetane value (51 minimum versus 40 minimum for mineral diesel)*Excellent lubricity

Disadvantages of biodiesel*Could harm certain elastomers (seals)*Has poor resistance to oxidation, especially when blended with ULSD. This results in spoilage and the formation of acids and varnishes*Biodiesel can absorb much more water than mineral diesel*Has lower energy content

Recommendation*If using biodiesel, fuel injection equipment manufacturers suggest a maximum of 5 percent (B5)

| biodiesel Vs Your Warranty machines

Imagine all the legal issues that can keep automotive manufacturers awake at night. Now, put yourself in the shoes of the companies behind the super-high-pressure diesel injection systems found in millions of cars and trucks. One mistake, and you could face warranty bills from multiple vehicle manufacturers representing hundreds of thousands of drivers (and millions of dollars!).

With that in mind, it's no wonder that biodiesel is being treated with caution by the fuel injection equipment (FIE) manufacturers-aka Bosch, Delphi, Denso, Siemens VDO, and Stanadyne. Although they support the development of alternative (non-petroleum) fuels in diesel engines, they are wary of unregulated biodiesel being used in equipment that was designed to run primarily on highly regulated #2 Diesel.

This is a gray area due to the wide variety of source materials used to make biodiesel, which means there are lots of undesirable finished products that could end up in your fuel tank. This kind of uncertainty can make FIE manufacturers toss and turn in their beds at night worrying about bad stuff roaming through their equipment such as:* Free methanol* Water* Free glycerine* Mono-, di-, and triglycerides* Free fatty acids* Solid particles* Oxidated fuel

So if your truck is under warranty and you want to run biodiesel, you'd better read this official statement by the FIE manufacturers before you fill the tank.

| biodiesel Vs Your Warranty machines

Imagine all the legal issues that can keep automotive manufacturers awake at night. Now, put yourself in the shoes of the companies behind the super-high-pressure diesel injection systems found in millions of cars and trucks. One mistake, and you could face warranty bills from multiple vehicle manufacturers representing hundreds of thousands of drivers (and millions of dollars!).

With that in mind, it's no wonder that biodiesel is being treated with caution by the fuel injection equipment (FIE) manufacturers-aka Bosch, Delphi, Denso, Siemens VDO, and Stanadyne. Although they support the development of alternative (non-petroleum) fuels in diesel engines, they are wary of unregulated biodiesel being used in equipment that was designed to run primarily on highly regulated #2 Diesel.

This is a gray area due to the wide variety of source materials used to make biodiesel, which means there are lots of undesirable finished products that could end up in your fuel tank. This kind of uncertainty can make FIE manufacturers toss and turn in their beds at night worrying about bad stuff roaming through their equipment such as:* Free methanol* Water* Free glycerine* Mono-, di-, and triglycerides* Free fatty acids* Solid particles* Oxidated fuel

So if your truck is under warranty and you want to run biodiesel, you'd better read this official statement by the FIE manufacturers before you fill the tank.