The number of four-wheel-drive vehicles grows every year for cars, trucks, and those crossovers in between. And as that crossover line blurs, so does the one that defines four-wheel drive. So many "modes" and "tracs" are on new trucks that even we have to climb underneath to sort them all out. A study of these various drive systems will help you decide what advantages one offers over another--if any at all--list who has what, and ponders if Newton really was on to something.

If you learn nothing else here, learn this: Four-wheel drive does not nullify the laws of gravity, physics, or common sense. Regardless of drive, only the tire patches connect you to the ground, high-centering or falling over notwithstanding. If you blister down a snow-covered grade with only tenuous grip, you'll learn the hard way that for every action there is a reaction, as you thud to a stop in a snow bank.

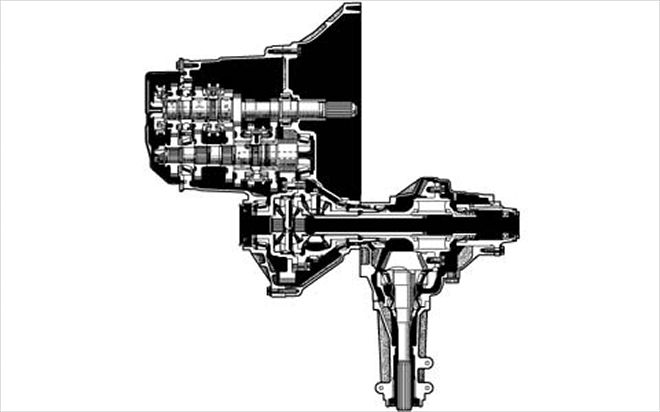

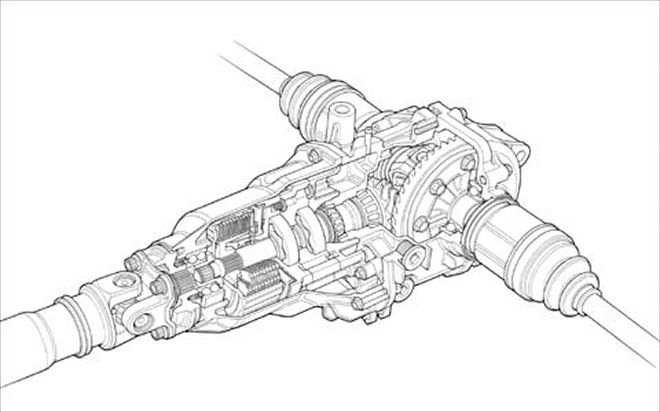

| A typical AWD system has a transversely mounted manual gearbox with an integral front differential, and a ring-and-pinion set to deliver power to the rear driveshaft.

Do You Need It? Four-wheel drive will help in acceleration and to a lesser extent in steering, because the front wheels are pulling in the direction preferred. But there's nothing to suggest a 4WD will stop better, as this is generally a function of brakes, tires, and vehicle weight. Four-wheel drives often come with better tires for adverse conditions and, in some cases, with better brakes (either upgraded to four discs or with ABS standard), but 4WDs weigh more as well, with some of that weight added over the already heavier front end. On the same tires with no brake differences, the 2WD will usually stop better.

A 4WD will offer more suitable traction, sometimes better ground clearance, occasionally improved ride quality derived from the larger tire sidewall, may sit higher for a superior view, and might win a "mine is bigger" driveway battle. For some trucks (Wrangler, Land Rover, Hummer), 4WD may be the only way you can get them.

On the other hand, 4WD will cost more (in the neighborhood of $2500-$3500). It will also cost more to keep, use tires and gasoline faster, and the extra driveline parts may add to routine--and unexpected--service bills. It will weigh more--anywhere from 200 to over 500 lb--depending on the model, and it may have a little less power because of packaging restrictions, especially in those AWD vehicles based on a front-driver. Finally, a 4WD might cost more to insure, though this is becoming less of an issue.

What Is It? At Truck Trend, we consider anything with four driven wheels and low-range gearing as four-wheel drive and anything without the low-range as all-wheel drive. Where four-wheel drive is mentioned hereafter, much of the information will apply to all-wheel drive as well (keep in mind gearing is where we make the distinction). We also reserve the term "part-time" for 4WD systems that operate as two-wheel drive (usually on the rear wheels) until the driver changes it by switch, pushbutton, or lever. The term "full-time" describes a 4WD system that always operates as a four-wheel drive, but with no driver-selectable 2WD option. It isn't necessary to agree with our definitions, but at least understand our slightly arbitrary classification system. See glossary for further clarification.

For example, we call the Range Rover and M-class full-time 4WD. They have low-range but not a 2WD option. The BMW X5 and Pontiac Aztek both qualify as AWD. Neither has low-range or driver-selectable 2WD, even though the Aztek operates normally as front-drive only and the X5 biases output to the rear. The Jeep Wrangler and Ford pickups are part-time 4WDs--the driver has to engage 4WD and both have low-range. Not coincidentally, neither can run 4WD on pavement.

| Honda's RealTime 4WD on the CR-V uses a gerotor-pump to apply pressure to a clutch pack. This "engages" the rear axle only when necessary and under load; under braking it disengages, and therefore has no effect on ABS.

These part-time 4WD systems are generally inexpensive, the least complex, and most likely manually operated. All part-time systems and many full-time systems also offer the ability to put the transfer case in Neutral, effectively disconnecting the engine and transmission from the wheels. This makes flat towing (with all four wheels on the ground) much simpler when using your truck as a motorhome dinghy, trail-only toy and makes it harder to steal.

Low-range gearing in any 4WD system is for torque multiplication. San Francisco streets are steep and require lots of throttle and torque converter slip to scale, but they pale in comparison to climbs in off-road conditions or the power required to turn a 100-lb tire buried in 200 lb of mud. Low-range reduction gearing, normally in the 2.00-2.7:1 range, is located in the transfer case, works on all forward and reverse gears and may be engaged by lever or switch. However, the gear change must be done with the vehicle stopped or nearly so.

Why Differentials? If we didn't have to turn and weren't concerned with noise and tire wear, trucks wouldn't need differentials. But every time a truck changes direction, the front wheels scribe a larger arc than the rear's, and the outside tires do the same relative to the inside tires. This can be accomplished without differentials, but makes steering difficult and locks everything together.

A differential allows wheels to operate with some independence, so that the inside tire doesn't travel the same distance as the outside tire or the rear tires the same as the front. In turn, the tire doesn't bark while it turns in place and the truck doesn't feel like it's trying to jack itself up (often referred to as "binding" or "driveline windup").

Applications A part-time four-wheel-drive system that will not be used on pavement needs only two differentials, one for each axle. In theory, a full-time four-wheel- or all-wheel-drive vehicle will need three differentials, one for each axle and one between the front and rear axles. However, as a wider variety of drive systems make their way into trucks and crossovers, a center differential is not always necessary.

Some AWD and full-time 4WD vehicles use torque split to maintain the driving dynamics of a 2WD. In vehicles derived from front drives, many are front drive normally and add rear drive as required: The amount of output transferred to the rear is often a function of strength--the Saturn VUE four-cylinder can direct 69-percent power to the rear, while the V-6 sends a maximum of 57 percent. Conversely, vehicles like the Escalade and X5 run a rear-biased torque split, usually near 1/3 or 2/3 percentage, which maintains the dynamics of a rear-drive system, while adding some front drive for directional stability and low-traction steering improvement. Systems like Infiniti/Nissan's All-Mode are designed to work in "auto" for best handling and performance and offer the "2WD" position primarily for dynamometer and emission testing.

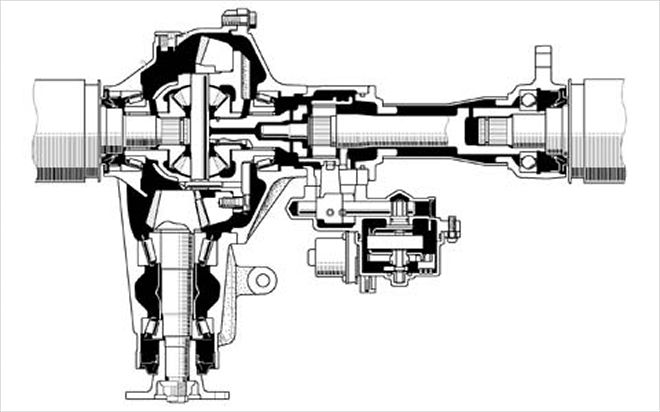

| A front axle disconnect system slides a collar (arrow) over two parts of the axle shaft so that both front wheels are driven. The collar may be powered by heat, electricity, vacuum, or hydraulics. This is a Toyota ADD system.

In vehicles derived from most two-wheel-drive trucks and sport/utilities, primary drive is to the rear. When four-wheel drive is selected, drive is added to the front axle from the transfer case. The connection between front and rear driveshafts in the transfer case is mechanically locked in part-time systems, which is why they can't be used on pavement where there is no tire slip. In full-time and AWD systems, the connection must have some means of allowing a small difference in front and rear driveshaft speeds so the truck can get around a corner without binding.

This can be accomplished by using another (center) differential in the transfer case, so front and rear drive can operate with some independence. In many cases this center differential may be locked (sometimes only in low range) for off-pavement use, as with the Hummer, earlier Range Rovers and Discoverys, and Chrysler's Selec-Trac.

Making Connections The connection may also be made by a viscous-coupling unit (VCU), a sealed canister or barrel-shaped device that's filled with thixotropic silicone fluid and a series of interwoven plates resembling CDs in a changer magazine. One set of these plates is attached to the drum shell, and the others are attached to a driveshaft through the middle. As the speed varies between the two sets of plates, because one driveshaft is rotating faster than the other (either by turning or by wheels slipping), the silicone reacts to the heat being generated by thickening, which in turn starts to limit the speed differential between the two sides of the VCU. This allows the slip necessary to avoid binding, without allowing one axle to spin while the other does nothing. Some VCUs have a locking function for off-road use (Montero, Range Rover) while others do not (Escalade).

Another alternative is an electro-magnetic clutch, initially used on Ford's 90's Aerostar AWD and now found in its ControlTrac (Expedition, Explorer, Navigator). This system uses an electromagnetic mechanism controlled by a computer receiving input from driveshaft speed sensors to variably apply pressure to a clutch pack in the transfer case. In "auto" this system defaults torque split 98 percent to the rear, adding front drive only as slip is detected. While the system can vary up to 100 percent output to the front, complete lack of traction at the back would imply at least partial loss at the front, so the front-axle assembly will not have to cope with all the engine's output. This is an important consideration--even a small V-8, run through low-range first gear at full throttle, could generate 10,000 lb-ft of torque to one axle, and many front axles simply won't take it.

Seamless Pressure Other options for separating front and rear drive are clutch packs like those found in automatic transmissions that are hydraulically powered (often externally) and add pressure as slip is determined, and gerotor-pump systems like that used in the Grand Cherokee's optional Quadra-Drive system.

AWD systems in cars rarely use a center differential, preferring some sort of clutch pack, hydraulic, electromagnetic, or electromechanical device for operation.

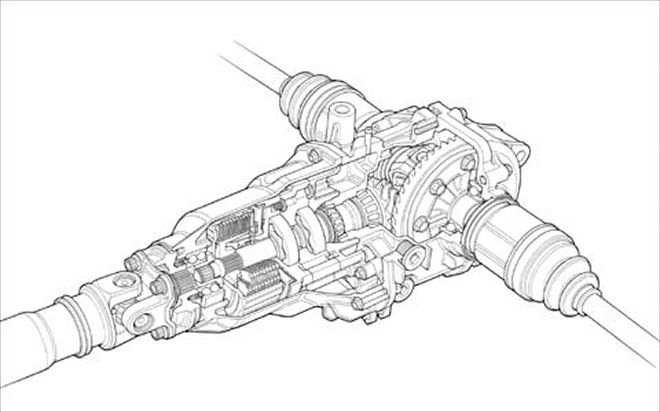

| The Acura MDX (and Honda Pilot) uses a series of electronically controlled wet clutches to transfer power front to back. A similar setup is used for the rear wheels.

Regardless of how power is applied to the front driveshaft in the above systems, the front axle itself must also be engaged. In the early Jeep days, the front axle was always connected, even if not being driven from the transfer case, as in 2WD. Then manual locking hubs were put on the end of the axles to connect the wheels.

Manual-locking hubs require you to physically rotate the hub to lock it and engage front drive. This is inconvenient, but it's inexpensive and means you can still drive if anything in the front drive breaks and allows use of any aftermarket front differential. Some enthusiasts have converted their vehicles to have locking hubs on the rear wheels as well. Whatever breaks in the driveline, as long as the wheel bearings are still good, can be pushed or towed home.

Automatic hubs replaced manual hubs as a question of convenience (you don't manually turn anything). Auto hubs are more complex than manual hubs, but less so than a disconnect system. The '03 Expedition uses a vacuum-powered hub disconnect that gives the same effect as auto hubs, but doesn't require slow speed or reversing direction to unlock front drive.

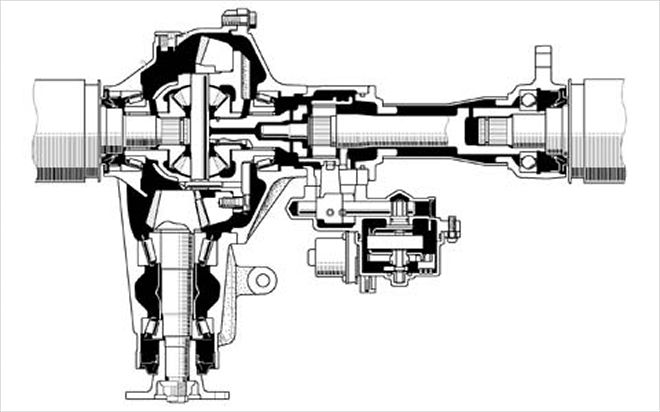

Feeling Disconnected The next advance is disconnect systems, like Toyota's ADD and GM's Insta-Trac. With this type of system there are no locking hubs and one front wheel is always linked to the front differential. The other wheel has a disconnect system on its axle shaft, which engages by a sliding sleeve or dog clutch--vacuum, heat, electric motor, or hydraulically powered--to link both front wheels to the differential. These systems are convenient, but don't always engage instantly, and aftermarket front differential options are limited because one side of the differential is always driven.

Some manufacturers, like Jeep, have come full circle and don't use any front-drive disengagement system on various models. These systems offer ultimate simplicity, but if anything breaks in the front drive, the vehicle may be undriveable, and aftermarket front-differential options are limited as with a disconnect system.

For those vehicles derived from front-drive cars or minivans, the AWD tends to use either a VCU for the front/rear connection (Vibe/Matrix, RAV4), or run primarily as front drivers adding rear drive only as required (MDX, CR-V, Rendezvous). In many of the latter cases, the driveshaft going from front to rear is always engaged, with the rear-drive engagement handled at the rear axle.

The VCU systems work the same way as 4WD transfer cases, with a limited amount of front/rear slip and drive to both ends all the time. The Aztek/Rendezvous and CR-V use a gerotor pump just ahead of the rear differential, which adds rear drive automatically and only when front slip is detected. The Acura MDX uses just one differential, between the front wheels, and is always driving its rear driveshaft. Instead of a conventional differential in back, it has a ring-and-pinion gearset with an electromagnetic clutch pack attached to each axle shaft. Wheel-speed sensors determine what is slipping where and engage the clutch packs individually as required, and since it's electronically controlled it can think ahead. If the vehicle is in first gear and the throttle is hit hard, the system knows the front tires will spin and add rear drive before tire spin actually happens.

Axle Differentials and Traction Control The axle differential is what enables the outside tire to travel further than the inside tire on a corner. In most standard applications, the differential is open, meaning it has no internal devices to minimize speed difference from side to side. With an open differential, a tire that loses traction will spin, while the other does little or nothing to propel the vehicle. That's why most four-wheel drives don't drive all the wheels equally. Open differentials are the least expensive, require no special maintenance (just routine gear-oil changes), have no affect on steering, and work best with most traction control and anti-lock systems. They allow independent control of each wheel.

A limited-slip differential does exactly that: limit the amount of slip side to side so the vehicle will corner comfortably but won't spin a tire excessively in loose traction situations. In new vehicles with fresh limited-slips, you often hear a scuffing noise from the inside rear tire on a tight turn, as it tries to travel a similar distance to the outside rear tire. Factory limited-slips, which generally add $200-$300 to the sticker, are often clutch-pack units, and since clutches are friction devices, they will, over time and miles, wear out and become unlimited-slips. Clutch material also ends up in the lubricating oil and may damage bearings if not changed. Names used for these differentials include Trac-Lok and PosiTraction, and clutch-pack limited-slips have only the slightest effect on steering, but do require a lubricant modifier when the fluid is changed. Other vehicles use a different approach to limited-slip, with the Hummer and Ranger FX4 packages choosing a Torsen (for torque-sensing) unit. In the Jeep Quadra-Drive system, a gerotor limited-slip is used in both front and rear axles.

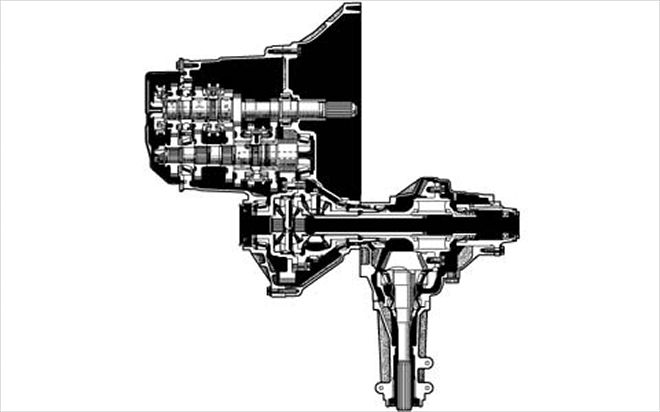

| The '03 Expedition uses a vacuum-operated hub disconnect system that allows the big SUV to run in 2WD, freewheeling the front tires. Flip to AWD and a series of clutch packs engage the front wheels.

The final option in axle differentials is a locking differential, and factory applications are limited to the rear axle on some Toyota products, HUMMER H2, and front and rear axles on the Mercedes-Benz G500 (which is why some consider it the only true 4WD factory-built vehicle in the U.S.). Some vehicles list a "locking differential" on the option sheet, though the majority are limited-slip devices and not true lockers.

A locking differential, when activated--by compressed air, electrically, or hydraulically--mechanically links the left and right axle shafts 100 percent, allowing no difference in left and right wheel speeds. On the trucks mentioned, the lockers are off in normal driving, so the differentials behave like open units and have no effect on handling or steering.

When the differential is locked, power is distributed equally left and right, so if one tire has good traction and the other is on ice or dangling in free air on a rutted trail, the vehicle will be propelled forward by the tire that has traction. Therein lies the principle disadvantage of a locking differential--with equal power to both sides, it tends to make the truck go straight ahead. This is further amplified with a locker in the front, because the steering wants one tire to go further than the other and the locker wants them to go the same distance. For that reason, a locking front differential should be used only when traction is minimal. Any aftermarket locking differential except those that can be unlocked, like the ARB Air Locker, must be equipped with locking hubs to isolate it from the steering on pavement.

The popularity of anti-lock brakes has made traction control an alternative to traction-aiding differentials such as limited-slips and lockers. ABS offers a means of both reading relative wheel speed and applying a brake at only one wheel, making electronic traction control a comparatively inexpensive addition.

If the sensors detect one wheel turning faster than the other side of the axle (or all three other tires), the ABS pump can apply brake pressure to the spinning wheel. This not only stops the spinning, but since power is not freely transmitted through that wheel, the open differential delivers some drive to the wheel that wasn't spinning. In some vehicles, if the applied braking action doesn't prove effective enough, throttle intervention cuts back engine power as well. This traction control is usually enough to keep going on road in snow or mud. However, in more serious conditions, electronic traction control may not be enough. It tends to take away power at times you need it most, and if the hill is long enough, it's possible to overheat some components.

Which system and options you choose will depend on your accurate assessment of requirements, availability, and cost. Along with the understanding that next year will always bring something new, as the '03 Range Rover, Hummer H2, and Jeep Wrangler Rubicon offer advances over today's versions.

| A typical AWD system has a transversely mounted manual gearbox with an integral front differential, and a ring-and-pinion set to deliver power to the rear driveshaft.

Do You Need It? Four-wheel drive will help in acceleration and to a lesser extent in steering, because the front wheels are pulling in the direction preferred. But there's nothing to suggest a 4WD will stop better, as this is generally a function of brakes, tires, and vehicle weight. Four-wheel drives often come with better tires for adverse conditions and, in some cases, with better brakes (either upgraded to four discs or with ABS standard), but 4WDs weigh more as well, with some of that weight added over the already heavier front end. On the same tires with no brake differences, the 2WD will usually stop better.

A 4WD will offer more suitable traction, sometimes better ground clearance, occasionally improved ride quality derived from the larger tire sidewall, may sit higher for a superior view, and might win a "mine is bigger" driveway battle. For some trucks (Wrangler, Land Rover, Hummer), 4WD may be the only way you can get them.

On the other hand, 4WD will cost more (in the neighborhood of $2500-$3500). It will also cost more to keep, use tires and gasoline faster, and the extra driveline parts may add to routine--and unexpected--service bills. It will weigh more--anywhere from 200 to over 500 lb--depending on the model, and it may have a little less power because of packaging restrictions, especially in those AWD vehicles based on a front-driver. Finally, a 4WD might cost more to insure, though this is becoming less of an issue.

What Is It? At Truck Trend, we consider anything with four driven wheels and low-range gearing as four-wheel drive and anything without the low-range as all-wheel drive. Where four-wheel drive is mentioned hereafter, much of the information will apply to all-wheel drive as well (keep in mind gearing is where we make the distinction). We also reserve the term "part-time" for 4WD systems that operate as two-wheel drive (usually on the rear wheels) until the driver changes it by switch, pushbutton, or lever. The term "full-time" describes a 4WD system that always operates as a four-wheel drive, but with no driver-selectable 2WD option. It isn't necessary to agree with our definitions, but at least understand our slightly arbitrary classification system. See glossary for further clarification.

For example, we call the Range Rover and M-class full-time 4WD. They have low-range but not a 2WD option. The BMW X5 and Pontiac Aztek both qualify as AWD. Neither has low-range or driver-selectable 2WD, even though the Aztek operates normally as front-drive only and the X5 biases output to the rear. The Jeep Wrangler and Ford pickups are part-time 4WDs--the driver has to engage 4WD and both have low-range. Not coincidentally, neither can run 4WD on pavement.

| A typical AWD system has a transversely mounted manual gearbox with an integral front differential, and a ring-and-pinion set to deliver power to the rear driveshaft.

Do You Need It? Four-wheel drive will help in acceleration and to a lesser extent in steering, because the front wheels are pulling in the direction preferred. But there's nothing to suggest a 4WD will stop better, as this is generally a function of brakes, tires, and vehicle weight. Four-wheel drives often come with better tires for adverse conditions and, in some cases, with better brakes (either upgraded to four discs or with ABS standard), but 4WDs weigh more as well, with some of that weight added over the already heavier front end. On the same tires with no brake differences, the 2WD will usually stop better.

A 4WD will offer more suitable traction, sometimes better ground clearance, occasionally improved ride quality derived from the larger tire sidewall, may sit higher for a superior view, and might win a "mine is bigger" driveway battle. For some trucks (Wrangler, Land Rover, Hummer), 4WD may be the only way you can get them.

On the other hand, 4WD will cost more (in the neighborhood of $2500-$3500). It will also cost more to keep, use tires and gasoline faster, and the extra driveline parts may add to routine--and unexpected--service bills. It will weigh more--anywhere from 200 to over 500 lb--depending on the model, and it may have a little less power because of packaging restrictions, especially in those AWD vehicles based on a front-driver. Finally, a 4WD might cost more to insure, though this is becoming less of an issue.

What Is It? At Truck Trend, we consider anything with four driven wheels and low-range gearing as four-wheel drive and anything without the low-range as all-wheel drive. Where four-wheel drive is mentioned hereafter, much of the information will apply to all-wheel drive as well (keep in mind gearing is where we make the distinction). We also reserve the term "part-time" for 4WD systems that operate as two-wheel drive (usually on the rear wheels) until the driver changes it by switch, pushbutton, or lever. The term "full-time" describes a 4WD system that always operates as a four-wheel drive, but with no driver-selectable 2WD option. It isn't necessary to agree with our definitions, but at least understand our slightly arbitrary classification system. See glossary for further clarification.

For example, we call the Range Rover and M-class full-time 4WD. They have low-range but not a 2WD option. The BMW X5 and Pontiac Aztek both qualify as AWD. Neither has low-range or driver-selectable 2WD, even though the Aztek operates normally as front-drive only and the X5 biases output to the rear. The Jeep Wrangler and Ford pickups are part-time 4WDs--the driver has to engage 4WD and both have low-range. Not coincidentally, neither can run 4WD on pavement.

| Honda's RealTime 4WD on the CR-V uses a gerotor-pump to apply pressure to a clutch pack. This "engages" the rear axle only when necessary and under load; under braking it disengages, and therefore has no effect on ABS.

These part-time 4WD systems are generally inexpensive, the least complex, and most likely manually operated. All part-time systems and many full-time systems also offer the ability to put the transfer case in Neutral, effectively disconnecting the engine and transmission from the wheels. This makes flat towing (with all four wheels on the ground) much simpler when using your truck as a motorhome dinghy, trail-only toy and makes it harder to steal.

Low-range gearing in any 4WD system is for torque multiplication. San Francisco streets are steep and require lots of throttle and torque converter slip to scale, but they pale in comparison to climbs in off-road conditions or the power required to turn a 100-lb tire buried in 200 lb of mud. Low-range reduction gearing, normally in the 2.00-2.7:1 range, is located in the transfer case, works on all forward and reverse gears and may be engaged by lever or switch. However, the gear change must be done with the vehicle stopped or nearly so.

Why Differentials? If we didn't have to turn and weren't concerned with noise and tire wear, trucks wouldn't need differentials. But every time a truck changes direction, the front wheels scribe a larger arc than the rear's, and the outside tires do the same relative to the inside tires. This can be accomplished without differentials, but makes steering difficult and locks everything together.

A differential allows wheels to operate with some independence, so that the inside tire doesn't travel the same distance as the outside tire or the rear tires the same as the front. In turn, the tire doesn't bark while it turns in place and the truck doesn't feel like it's trying to jack itself up (often referred to as "binding" or "driveline windup").

Applications A part-time four-wheel-drive system that will not be used on pavement needs only two differentials, one for each axle. In theory, a full-time four-wheel- or all-wheel-drive vehicle will need three differentials, one for each axle and one between the front and rear axles. However, as a wider variety of drive systems make their way into trucks and crossovers, a center differential is not always necessary.

Some AWD and full-time 4WD vehicles use torque split to maintain the driving dynamics of a 2WD. In vehicles derived from front drives, many are front drive normally and add rear drive as required: The amount of output transferred to the rear is often a function of strength--the Saturn VUE four-cylinder can direct 69-percent power to the rear, while the V-6 sends a maximum of 57 percent. Conversely, vehicles like the Escalade and X5 run a rear-biased torque split, usually near 1/3 or 2/3 percentage, which maintains the dynamics of a rear-drive system, while adding some front drive for directional stability and low-traction steering improvement. Systems like Infiniti/Nissan's All-Mode are designed to work in "auto" for best handling and performance and offer the "2WD" position primarily for dynamometer and emission testing.

| Honda's RealTime 4WD on the CR-V uses a gerotor-pump to apply pressure to a clutch pack. This "engages" the rear axle only when necessary and under load; under braking it disengages, and therefore has no effect on ABS.

These part-time 4WD systems are generally inexpensive, the least complex, and most likely manually operated. All part-time systems and many full-time systems also offer the ability to put the transfer case in Neutral, effectively disconnecting the engine and transmission from the wheels. This makes flat towing (with all four wheels on the ground) much simpler when using your truck as a motorhome dinghy, trail-only toy and makes it harder to steal.

Low-range gearing in any 4WD system is for torque multiplication. San Francisco streets are steep and require lots of throttle and torque converter slip to scale, but they pale in comparison to climbs in off-road conditions or the power required to turn a 100-lb tire buried in 200 lb of mud. Low-range reduction gearing, normally in the 2.00-2.7:1 range, is located in the transfer case, works on all forward and reverse gears and may be engaged by lever or switch. However, the gear change must be done with the vehicle stopped or nearly so.

Why Differentials? If we didn't have to turn and weren't concerned with noise and tire wear, trucks wouldn't need differentials. But every time a truck changes direction, the front wheels scribe a larger arc than the rear's, and the outside tires do the same relative to the inside tires. This can be accomplished without differentials, but makes steering difficult and locks everything together.

A differential allows wheels to operate with some independence, so that the inside tire doesn't travel the same distance as the outside tire or the rear tires the same as the front. In turn, the tire doesn't bark while it turns in place and the truck doesn't feel like it's trying to jack itself up (often referred to as "binding" or "driveline windup").

Applications A part-time four-wheel-drive system that will not be used on pavement needs only two differentials, one for each axle. In theory, a full-time four-wheel- or all-wheel-drive vehicle will need three differentials, one for each axle and one between the front and rear axles. However, as a wider variety of drive systems make their way into trucks and crossovers, a center differential is not always necessary.

Some AWD and full-time 4WD vehicles use torque split to maintain the driving dynamics of a 2WD. In vehicles derived from front drives, many are front drive normally and add rear drive as required: The amount of output transferred to the rear is often a function of strength--the Saturn VUE four-cylinder can direct 69-percent power to the rear, while the V-6 sends a maximum of 57 percent. Conversely, vehicles like the Escalade and X5 run a rear-biased torque split, usually near 1/3 or 2/3 percentage, which maintains the dynamics of a rear-drive system, while adding some front drive for directional stability and low-traction steering improvement. Systems like Infiniti/Nissan's All-Mode are designed to work in "auto" for best handling and performance and offer the "2WD" position primarily for dynamometer and emission testing.

| A front axle disconnect system slides a collar (arrow) over two parts of the axle shaft so that both front wheels are driven. The collar may be powered by heat, electricity, vacuum, or hydraulics. This is a Toyota ADD system.

In vehicles derived from most two-wheel-drive trucks and sport/utilities, primary drive is to the rear. When four-wheel drive is selected, drive is added to the front axle from the transfer case. The connection between front and rear driveshafts in the transfer case is mechanically locked in part-time systems, which is why they can't be used on pavement where there is no tire slip. In full-time and AWD systems, the connection must have some means of allowing a small difference in front and rear driveshaft speeds so the truck can get around a corner without binding.

This can be accomplished by using another (center) differential in the transfer case, so front and rear drive can operate with some independence. In many cases this center differential may be locked (sometimes only in low range) for off-pavement use, as with the Hummer, earlier Range Rovers and Discoverys, and Chrysler's Selec-Trac.

Making Connections The connection may also be made by a viscous-coupling unit (VCU), a sealed canister or barrel-shaped device that's filled with thixotropic silicone fluid and a series of interwoven plates resembling CDs in a changer magazine. One set of these plates is attached to the drum shell, and the others are attached to a driveshaft through the middle. As the speed varies between the two sets of plates, because one driveshaft is rotating faster than the other (either by turning or by wheels slipping), the silicone reacts to the heat being generated by thickening, which in turn starts to limit the speed differential between the two sides of the VCU. This allows the slip necessary to avoid binding, without allowing one axle to spin while the other does nothing. Some VCUs have a locking function for off-road use (Montero, Range Rover) while others do not (Escalade).

Another alternative is an electro-magnetic clutch, initially used on Ford's 90's Aerostar AWD and now found in its ControlTrac (Expedition, Explorer, Navigator). This system uses an electromagnetic mechanism controlled by a computer receiving input from driveshaft speed sensors to variably apply pressure to a clutch pack in the transfer case. In "auto" this system defaults torque split 98 percent to the rear, adding front drive only as slip is detected. While the system can vary up to 100 percent output to the front, complete lack of traction at the back would imply at least partial loss at the front, so the front-axle assembly will not have to cope with all the engine's output. This is an important consideration--even a small V-8, run through low-range first gear at full throttle, could generate 10,000 lb-ft of torque to one axle, and many front axles simply won't take it.

Seamless Pressure Other options for separating front and rear drive are clutch packs like those found in automatic transmissions that are hydraulically powered (often externally) and add pressure as slip is determined, and gerotor-pump systems like that used in the Grand Cherokee's optional Quadra-Drive system.

AWD systems in cars rarely use a center differential, preferring some sort of clutch pack, hydraulic, electromagnetic, or electromechanical device for operation.

| A front axle disconnect system slides a collar (arrow) over two parts of the axle shaft so that both front wheels are driven. The collar may be powered by heat, electricity, vacuum, or hydraulics. This is a Toyota ADD system.

In vehicles derived from most two-wheel-drive trucks and sport/utilities, primary drive is to the rear. When four-wheel drive is selected, drive is added to the front axle from the transfer case. The connection between front and rear driveshafts in the transfer case is mechanically locked in part-time systems, which is why they can't be used on pavement where there is no tire slip. In full-time and AWD systems, the connection must have some means of allowing a small difference in front and rear driveshaft speeds so the truck can get around a corner without binding.

This can be accomplished by using another (center) differential in the transfer case, so front and rear drive can operate with some independence. In many cases this center differential may be locked (sometimes only in low range) for off-pavement use, as with the Hummer, earlier Range Rovers and Discoverys, and Chrysler's Selec-Trac.

Making Connections The connection may also be made by a viscous-coupling unit (VCU), a sealed canister or barrel-shaped device that's filled with thixotropic silicone fluid and a series of interwoven plates resembling CDs in a changer magazine. One set of these plates is attached to the drum shell, and the others are attached to a driveshaft through the middle. As the speed varies between the two sets of plates, because one driveshaft is rotating faster than the other (either by turning or by wheels slipping), the silicone reacts to the heat being generated by thickening, which in turn starts to limit the speed differential between the two sides of the VCU. This allows the slip necessary to avoid binding, without allowing one axle to spin while the other does nothing. Some VCUs have a locking function for off-road use (Montero, Range Rover) while others do not (Escalade).

Another alternative is an electro-magnetic clutch, initially used on Ford's 90's Aerostar AWD and now found in its ControlTrac (Expedition, Explorer, Navigator). This system uses an electromagnetic mechanism controlled by a computer receiving input from driveshaft speed sensors to variably apply pressure to a clutch pack in the transfer case. In "auto" this system defaults torque split 98 percent to the rear, adding front drive only as slip is detected. While the system can vary up to 100 percent output to the front, complete lack of traction at the back would imply at least partial loss at the front, so the front-axle assembly will not have to cope with all the engine's output. This is an important consideration--even a small V-8, run through low-range first gear at full throttle, could generate 10,000 lb-ft of torque to one axle, and many front axles simply won't take it.

Seamless Pressure Other options for separating front and rear drive are clutch packs like those found in automatic transmissions that are hydraulically powered (often externally) and add pressure as slip is determined, and gerotor-pump systems like that used in the Grand Cherokee's optional Quadra-Drive system.

AWD systems in cars rarely use a center differential, preferring some sort of clutch pack, hydraulic, electromagnetic, or electromechanical device for operation.

| The Acura MDX (and Honda Pilot) uses a series of electronically controlled wet clutches to transfer power front to back. A similar setup is used for the rear wheels.

Regardless of how power is applied to the front driveshaft in the above systems, the front axle itself must also be engaged. In the early Jeep days, the front axle was always connected, even if not being driven from the transfer case, as in 2WD. Then manual locking hubs were put on the end of the axles to connect the wheels.

Manual-locking hubs require you to physically rotate the hub to lock it and engage front drive. This is inconvenient, but it's inexpensive and means you can still drive if anything in the front drive breaks and allows use of any aftermarket front differential. Some enthusiasts have converted their vehicles to have locking hubs on the rear wheels as well. Whatever breaks in the driveline, as long as the wheel bearings are still good, can be pushed or towed home.

Automatic hubs replaced manual hubs as a question of convenience (you don't manually turn anything). Auto hubs are more complex than manual hubs, but less so than a disconnect system. The '03 Expedition uses a vacuum-powered hub disconnect that gives the same effect as auto hubs, but doesn't require slow speed or reversing direction to unlock front drive.

Feeling Disconnected The next advance is disconnect systems, like Toyota's ADD and GM's Insta-Trac. With this type of system there are no locking hubs and one front wheel is always linked to the front differential. The other wheel has a disconnect system on its axle shaft, which engages by a sliding sleeve or dog clutch--vacuum, heat, electric motor, or hydraulically powered--to link both front wheels to the differential. These systems are convenient, but don't always engage instantly, and aftermarket front differential options are limited because one side of the differential is always driven.

Some manufacturers, like Jeep, have come full circle and don't use any front-drive disengagement system on various models. These systems offer ultimate simplicity, but if anything breaks in the front drive, the vehicle may be undriveable, and aftermarket front-differential options are limited as with a disconnect system.

For those vehicles derived from front-drive cars or minivans, the AWD tends to use either a VCU for the front/rear connection (Vibe/Matrix, RAV4), or run primarily as front drivers adding rear drive only as required (MDX, CR-V, Rendezvous). In many of the latter cases, the driveshaft going from front to rear is always engaged, with the rear-drive engagement handled at the rear axle.

The VCU systems work the same way as 4WD transfer cases, with a limited amount of front/rear slip and drive to both ends all the time. The Aztek/Rendezvous and CR-V use a gerotor pump just ahead of the rear differential, which adds rear drive automatically and only when front slip is detected. The Acura MDX uses just one differential, between the front wheels, and is always driving its rear driveshaft. Instead of a conventional differential in back, it has a ring-and-pinion gearset with an electromagnetic clutch pack attached to each axle shaft. Wheel-speed sensors determine what is slipping where and engage the clutch packs individually as required, and since it's electronically controlled it can think ahead. If the vehicle is in first gear and the throttle is hit hard, the system knows the front tires will spin and add rear drive before tire spin actually happens.

Axle Differentials and Traction Control The axle differential is what enables the outside tire to travel further than the inside tire on a corner. In most standard applications, the differential is open, meaning it has no internal devices to minimize speed difference from side to side. With an open differential, a tire that loses traction will spin, while the other does little or nothing to propel the vehicle. That's why most four-wheel drives don't drive all the wheels equally. Open differentials are the least expensive, require no special maintenance (just routine gear-oil changes), have no affect on steering, and work best with most traction control and anti-lock systems. They allow independent control of each wheel.

A limited-slip differential does exactly that: limit the amount of slip side to side so the vehicle will corner comfortably but won't spin a tire excessively in loose traction situations. In new vehicles with fresh limited-slips, you often hear a scuffing noise from the inside rear tire on a tight turn, as it tries to travel a similar distance to the outside rear tire. Factory limited-slips, which generally add $200-$300 to the sticker, are often clutch-pack units, and since clutches are friction devices, they will, over time and miles, wear out and become unlimited-slips. Clutch material also ends up in the lubricating oil and may damage bearings if not changed. Names used for these differentials include Trac-Lok and PosiTraction, and clutch-pack limited-slips have only the slightest effect on steering, but do require a lubricant modifier when the fluid is changed. Other vehicles use a different approach to limited-slip, with the Hummer and Ranger FX4 packages choosing a Torsen (for torque-sensing) unit. In the Jeep Quadra-Drive system, a gerotor limited-slip is used in both front and rear axles.

| The Acura MDX (and Honda Pilot) uses a series of electronically controlled wet clutches to transfer power front to back. A similar setup is used for the rear wheels.

Regardless of how power is applied to the front driveshaft in the above systems, the front axle itself must also be engaged. In the early Jeep days, the front axle was always connected, even if not being driven from the transfer case, as in 2WD. Then manual locking hubs were put on the end of the axles to connect the wheels.

Manual-locking hubs require you to physically rotate the hub to lock it and engage front drive. This is inconvenient, but it's inexpensive and means you can still drive if anything in the front drive breaks and allows use of any aftermarket front differential. Some enthusiasts have converted their vehicles to have locking hubs on the rear wheels as well. Whatever breaks in the driveline, as long as the wheel bearings are still good, can be pushed or towed home.

Automatic hubs replaced manual hubs as a question of convenience (you don't manually turn anything). Auto hubs are more complex than manual hubs, but less so than a disconnect system. The '03 Expedition uses a vacuum-powered hub disconnect that gives the same effect as auto hubs, but doesn't require slow speed or reversing direction to unlock front drive.

Feeling Disconnected The next advance is disconnect systems, like Toyota's ADD and GM's Insta-Trac. With this type of system there are no locking hubs and one front wheel is always linked to the front differential. The other wheel has a disconnect system on its axle shaft, which engages by a sliding sleeve or dog clutch--vacuum, heat, electric motor, or hydraulically powered--to link both front wheels to the differential. These systems are convenient, but don't always engage instantly, and aftermarket front differential options are limited because one side of the differential is always driven.

Some manufacturers, like Jeep, have come full circle and don't use any front-drive disengagement system on various models. These systems offer ultimate simplicity, but if anything breaks in the front drive, the vehicle may be undriveable, and aftermarket front-differential options are limited as with a disconnect system.

For those vehicles derived from front-drive cars or minivans, the AWD tends to use either a VCU for the front/rear connection (Vibe/Matrix, RAV4), or run primarily as front drivers adding rear drive only as required (MDX, CR-V, Rendezvous). In many of the latter cases, the driveshaft going from front to rear is always engaged, with the rear-drive engagement handled at the rear axle.

The VCU systems work the same way as 4WD transfer cases, with a limited amount of front/rear slip and drive to both ends all the time. The Aztek/Rendezvous and CR-V use a gerotor pump just ahead of the rear differential, which adds rear drive automatically and only when front slip is detected. The Acura MDX uses just one differential, between the front wheels, and is always driving its rear driveshaft. Instead of a conventional differential in back, it has a ring-and-pinion gearset with an electromagnetic clutch pack attached to each axle shaft. Wheel-speed sensors determine what is slipping where and engage the clutch packs individually as required, and since it's electronically controlled it can think ahead. If the vehicle is in first gear and the throttle is hit hard, the system knows the front tires will spin and add rear drive before tire spin actually happens.

Axle Differentials and Traction Control The axle differential is what enables the outside tire to travel further than the inside tire on a corner. In most standard applications, the differential is open, meaning it has no internal devices to minimize speed difference from side to side. With an open differential, a tire that loses traction will spin, while the other does little or nothing to propel the vehicle. That's why most four-wheel drives don't drive all the wheels equally. Open differentials are the least expensive, require no special maintenance (just routine gear-oil changes), have no affect on steering, and work best with most traction control and anti-lock systems. They allow independent control of each wheel.

A limited-slip differential does exactly that: limit the amount of slip side to side so the vehicle will corner comfortably but won't spin a tire excessively in loose traction situations. In new vehicles with fresh limited-slips, you often hear a scuffing noise from the inside rear tire on a tight turn, as it tries to travel a similar distance to the outside rear tire. Factory limited-slips, which generally add $200-$300 to the sticker, are often clutch-pack units, and since clutches are friction devices, they will, over time and miles, wear out and become unlimited-slips. Clutch material also ends up in the lubricating oil and may damage bearings if not changed. Names used for these differentials include Trac-Lok and PosiTraction, and clutch-pack limited-slips have only the slightest effect on steering, but do require a lubricant modifier when the fluid is changed. Other vehicles use a different approach to limited-slip, with the Hummer and Ranger FX4 packages choosing a Torsen (for torque-sensing) unit. In the Jeep Quadra-Drive system, a gerotor limited-slip is used in both front and rear axles.

| The '03 Expedition uses a vacuum-operated hub disconnect system that allows the big SUV to run in 2WD, freewheeling the front tires. Flip to AWD and a series of clutch packs engage the front wheels.

The final option in axle differentials is a locking differential, and factory applications are limited to the rear axle on some Toyota products, HUMMER H2, and front and rear axles on the Mercedes-Benz G500 (which is why some consider it the only true 4WD factory-built vehicle in the U.S.). Some vehicles list a "locking differential" on the option sheet, though the majority are limited-slip devices and not true lockers.

A locking differential, when activated--by compressed air, electrically, or hydraulically--mechanically links the left and right axle shafts 100 percent, allowing no difference in left and right wheel speeds. On the trucks mentioned, the lockers are off in normal driving, so the differentials behave like open units and have no effect on handling or steering.

When the differential is locked, power is distributed equally left and right, so if one tire has good traction and the other is on ice or dangling in free air on a rutted trail, the vehicle will be propelled forward by the tire that has traction. Therein lies the principle disadvantage of a locking differential--with equal power to both sides, it tends to make the truck go straight ahead. This is further amplified with a locker in the front, because the steering wants one tire to go further than the other and the locker wants them to go the same distance. For that reason, a locking front differential should be used only when traction is minimal. Any aftermarket locking differential except those that can be unlocked, like the ARB Air Locker, must be equipped with locking hubs to isolate it from the steering on pavement.

The popularity of anti-lock brakes has made traction control an alternative to traction-aiding differentials such as limited-slips and lockers. ABS offers a means of both reading relative wheel speed and applying a brake at only one wheel, making electronic traction control a comparatively inexpensive addition.

If the sensors detect one wheel turning faster than the other side of the axle (or all three other tires), the ABS pump can apply brake pressure to the spinning wheel. This not only stops the spinning, but since power is not freely transmitted through that wheel, the open differential delivers some drive to the wheel that wasn't spinning. In some vehicles, if the applied braking action doesn't prove effective enough, throttle intervention cuts back engine power as well. This traction control is usually enough to keep going on road in snow or mud. However, in more serious conditions, electronic traction control may not be enough. It tends to take away power at times you need it most, and if the hill is long enough, it's possible to overheat some components.

Which system and options you choose will depend on your accurate assessment of requirements, availability, and cost. Along with the understanding that next year will always bring something new, as the '03 Range Rover, Hummer H2, and Jeep Wrangler Rubicon offer advances over today's versions.

| The '03 Expedition uses a vacuum-operated hub disconnect system that allows the big SUV to run in 2WD, freewheeling the front tires. Flip to AWD and a series of clutch packs engage the front wheels.

The final option in axle differentials is a locking differential, and factory applications are limited to the rear axle on some Toyota products, HUMMER H2, and front and rear axles on the Mercedes-Benz G500 (which is why some consider it the only true 4WD factory-built vehicle in the U.S.). Some vehicles list a "locking differential" on the option sheet, though the majority are limited-slip devices and not true lockers.

A locking differential, when activated--by compressed air, electrically, or hydraulically--mechanically links the left and right axle shafts 100 percent, allowing no difference in left and right wheel speeds. On the trucks mentioned, the lockers are off in normal driving, so the differentials behave like open units and have no effect on handling or steering.

When the differential is locked, power is distributed equally left and right, so if one tire has good traction and the other is on ice or dangling in free air on a rutted trail, the vehicle will be propelled forward by the tire that has traction. Therein lies the principle disadvantage of a locking differential--with equal power to both sides, it tends to make the truck go straight ahead. This is further amplified with a locker in the front, because the steering wants one tire to go further than the other and the locker wants them to go the same distance. For that reason, a locking front differential should be used only when traction is minimal. Any aftermarket locking differential except those that can be unlocked, like the ARB Air Locker, must be equipped with locking hubs to isolate it from the steering on pavement.

The popularity of anti-lock brakes has made traction control an alternative to traction-aiding differentials such as limited-slips and lockers. ABS offers a means of both reading relative wheel speed and applying a brake at only one wheel, making electronic traction control a comparatively inexpensive addition.

If the sensors detect one wheel turning faster than the other side of the axle (or all three other tires), the ABS pump can apply brake pressure to the spinning wheel. This not only stops the spinning, but since power is not freely transmitted through that wheel, the open differential delivers some drive to the wheel that wasn't spinning. In some vehicles, if the applied braking action doesn't prove effective enough, throttle intervention cuts back engine power as well. This traction control is usually enough to keep going on road in snow or mud. However, in more serious conditions, electronic traction control may not be enough. It tends to take away power at times you need it most, and if the hill is long enough, it's possible to overheat some components.

Which system and options you choose will depend on your accurate assessment of requirements, availability, and cost. Along with the understanding that next year will always bring something new, as the '03 Range Rover, Hummer H2, and Jeep Wrangler Rubicon offer advances over today's versions.