Reliability is a necessity for both stock and modified work trucks. There's nothing that'll turn a stomach upside down faster than turning the key to your pride and joy (and livelihood!) and having nothing happen. Talk about an added stressor to jam-packed workweeks! You have to have confidence your truck will start each and every time, which, unfortunately, even under best-case scenarios, requires an attentive level of service and maintenance.

With just a hair more than 50,000 miles on the odometer, our 6.7L Cummins-powered '09 Dodge Ram 2500 was fine one day and would not even try to start the next. Sitting well within the bounds of a low-mile vehicle and not having any reliability-altering modifications, we were surprised that our trusty Dodge had pooped out. While not relegated purely to street duty, the last intense off-road trip had come and gone months ago, problem-free. The only warning had been one hesitant (but successful) start the day before. Follow along as we explore some troubleshooting tips for getting our down-and-out rig back to action.

Our problem lay within the electrical system, so we took care to troubleshoot systematically, thoroughly, and logically. Upon entry to the truck, all the lighting and auxiliary systems were working great. Our AMP Research steps dropped down nicely, the interior LED lighting was bright, and the dash was illuminated as usual. However, one turn of the ignition key revealed a different story, as the mighty Cummins didn't turn a single revolution and refused to budge. The key-on sequence did reveal the starter solenoid to be working as intended with a loud clank of the bendix engaging the starter gear against the flywheel, but there was no motion beyond that point. We could say the starter solenoid was doing its job since there would have been no current sent to the starter if otherwise. The next step was to look at the batteries to see what we could find.

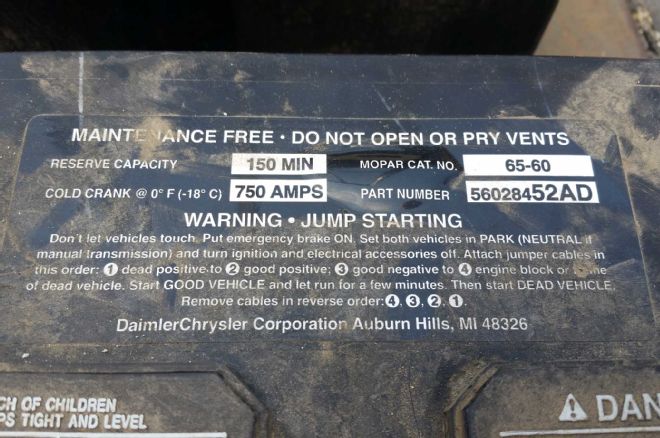

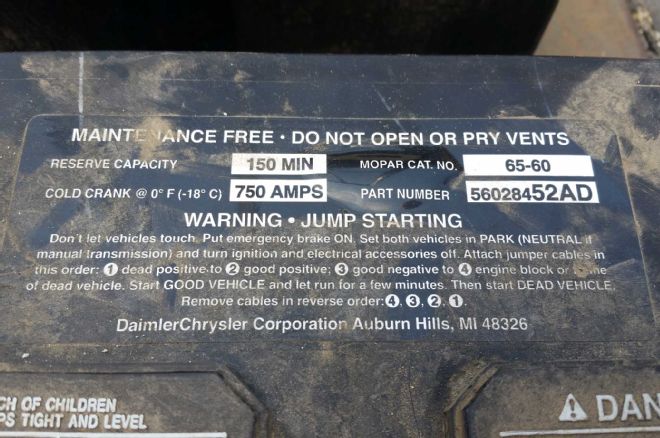

Since the truck had the Cummins engine, it was fitted with twin Group 65 750CCA main batteries from the factory. These larger diesel engines need the extended amperage capabilities of the dual batteries to start them in inclement conditions. The majority of the diesel engines are fitted with glow plugs that draw a significant amount of current while they warm up; this is why you should wait to start the vehicle until it indicates it's ready. However, our Dodge does not have glow plugs, so we could rule that out immediately. We grabbed our trusty voltmeter to check the static voltage of the batteries together and found them to be in the 12-volt range, which should be plenty sufficient to start the engine. In the case of dual batteries, though, checking the voltage is not a straightforward job. The batteries must be disconnected from one another to get a true reading of each one's health. Sure enough, we found the passenger-side battery to be right at 12 volts and the driver-side battery to be below 10 volts.

Knowing our driver-side battery was likely the culprit, we proceeded to load-check the batteries individually. This would help assess the driver-side unit's ability to recharge and work properly if we threw it on the charger. We hooked up a simple 12-volt halogen light to the terminals on the battery along with our meter to monitor the voltage drop. If the battery could hold a load, the voltage would drop to a certain point and then drop very slowly as the battery holds a load but is depleted. If the voltage drops constantly with no foreseeable slowing, it cannot hold a load and must be replaced. The passenger-side battery held a load admirably. The driver-side battery was still dropping like a rock at 8 volts, revealing it to be our smoking gun in this whole issue.

With a quick trip to the local auto parts store, we scored two fresh batteries with an upgraded 850CCA/1000CA rating. It is important to note that in dual main battery vehicles, both batteries must be changed out with a job like this. We proved that our passenger-side battery was good and still held a load, however, if we installed a fresh driver-side battery and left the passenger-side unit in place, we could expect both batteries to have a reduced life compared to two new units. Once the new batteries were installed and the terminal lugs tightened, the Cummins cranked vigorously and woke up from its slumber with ease.

Sometimes even the most basic maintenance procedures can prove tricky to diagnose, but with a little patience and thorough troubleshooting, all problems can be solved. In our case, a simple battery failure was to blame, but we got lucky this time as no-start issues can get very complicated and costly in a hurry.

| How To Troubleshoot A Battery Failure Engine Starting Batteries

| How To Troubleshoot A Battery Failure Engine Starting Battery

Our '09 Dodge Ram 2500 has two engine-starting batteries located on both fenderwells, which lasted 50,000 miles before needing replacement. Packing 750CCA, the stock batteries were plenty sufficient when operating correctly. However, daily rigors and hard front-end hits from moderate off-roading had shortened their lifespan.

| How To Troubleshoot A Battery Failure After Market Battery

Aftermarket batteries were installed with an upgraded 850CCA (0 degrees)/1000CA (32 degrees) for added starting capabilities and additional reserve capacity. Since it gets really expensive quickly to just start throwing parts at a truck to solve problems, be sure you've diagnosed the real problem and, likewise, the real fix.

| How To Troubleshoot A Battery Failure Battery Install

It is important to install the red/12-volt sides of both batteries first, followed by the grounds. This eliminates any chance of arcing to a grounded location.

| How To Troubleshoot A Battery Failure Battery Blanket Mounts Lugs

The original battery blankets, mounts, and lugs were all reinstalled as delivered from the factory.

| How To Troubleshoot A Battery Failure Voltage Check

Once the batteries were buttoned up, we fired the Cummins engine and checked for proper running voltage and alternator function. With 14.5 volts we were good to go. Relieved that the best-case scenario for the no-start situation was battery-related, we returned to the truck projects we really wanted to be working on.

| How To Troubleshoot A Battery Failure Engine Starting Batteries

| How To Troubleshoot A Battery Failure Engine Starting Batteries

| How To Troubleshoot A Battery Failure Engine Starting Battery

Our '09 Dodge Ram 2500 has two engine-starting batteries located on both fenderwells, which lasted 50,000 miles before needing replacement. Packing 750CCA, the stock batteries were plenty sufficient when operating correctly. However, daily rigors and hard front-end hits from moderate off-roading had shortened their lifespan.

| How To Troubleshoot A Battery Failure Engine Starting Battery

Our '09 Dodge Ram 2500 has two engine-starting batteries located on both fenderwells, which lasted 50,000 miles before needing replacement. Packing 750CCA, the stock batteries were plenty sufficient when operating correctly. However, daily rigors and hard front-end hits from moderate off-roading had shortened their lifespan.

| How To Troubleshoot A Battery Failure After Market Battery

Aftermarket batteries were installed with an upgraded 850CCA (0 degrees)/1000CA (32 degrees) for added starting capabilities and additional reserve capacity. Since it gets really expensive quickly to just start throwing parts at a truck to solve problems, be sure you've diagnosed the real problem and, likewise, the real fix.

| How To Troubleshoot A Battery Failure After Market Battery

Aftermarket batteries were installed with an upgraded 850CCA (0 degrees)/1000CA (32 degrees) for added starting capabilities and additional reserve capacity. Since it gets really expensive quickly to just start throwing parts at a truck to solve problems, be sure you've diagnosed the real problem and, likewise, the real fix.

| How To Troubleshoot A Battery Failure Battery Install

It is important to install the red/12-volt sides of both batteries first, followed by the grounds. This eliminates any chance of arcing to a grounded location.

| How To Troubleshoot A Battery Failure Battery Install

It is important to install the red/12-volt sides of both batteries first, followed by the grounds. This eliminates any chance of arcing to a grounded location.

| How To Troubleshoot A Battery Failure Battery Blanket Mounts Lugs

The original battery blankets, mounts, and lugs were all reinstalled as delivered from the factory.

| How To Troubleshoot A Battery Failure Battery Blanket Mounts Lugs

The original battery blankets, mounts, and lugs were all reinstalled as delivered from the factory.

| How To Troubleshoot A Battery Failure Voltage Check

Once the batteries were buttoned up, we fired the Cummins engine and checked for proper running voltage and alternator function. With 14.5 volts we were good to go. Relieved that the best-case scenario for the no-start situation was battery-related, we returned to the truck projects we really wanted to be working on.

| How To Troubleshoot A Battery Failure Voltage Check

Once the batteries were buttoned up, we fired the Cummins engine and checked for proper running voltage and alternator function. With 14.5 volts we were good to go. Relieved that the best-case scenario for the no-start situation was battery-related, we returned to the truck projects we really wanted to be working on.