Custom Bodywork on a Chevy S10 - Smooth A Dime

| smooth A Dime chevrolet S10

Back in the May issue, in the story titled "Silverado Styling Staples," we reported how Drew Brothers Customs (DBC) in Arizona tackled some of the more common modifications, such as shaving, painting, and swapping out body parts. The story focused on a fullsize GM truck in the beginning phases of a mild custom build. We say "mild" because other than the shaved tailgate handle, the truck was customized with mainly bolt-on GM parts. Since this is our S-10 Special, we will dive deeper into the custom realm by getting into shaving all the handles, adding door solenoids, and molding in the steel roll pan. These are the kinds of modifications that have almost become standard in the S-10 class. S-10's are usually used as a guinea pig because they are an entry-level truck that, with some good searching, can be bought for a steal. All we have to say is, Thank goodness for that. If everything cost twenty of thirty grand, not many people would be cutting them up.

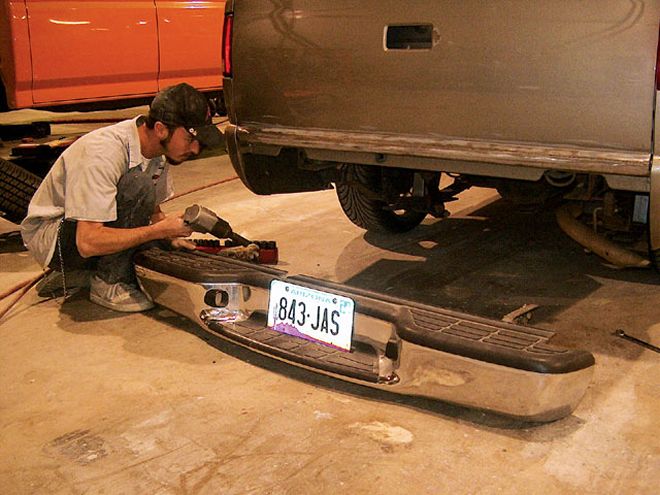

The parts list for this story is pretty short, consisting of a door kit from AutoLoc and a steel roll pan from AIM. Other than that, it's all about patience and talent. For the latter, we looked to the brothers Drew, the self-proclaimed merchants of cool, and Scott Deheart. Scott is one of many experienced guys out there slinging mud in the hot Arizona weather while Rob and Rich Drew chow down at the waffle house. This S-10 we will be following along with happens to be Scott's personal ride; we were lucky enough to catch him the last time we were in Arizona and asked him to wait for us.

We watched as Scott deleted all the exterior handles on his Dime using every bit of patience he had to keep the stuff from warping. There are a few key points to a nice shave job. One is to get the patch panel in with the least amount of warpage to the metal. That means taking your time and tack-welding the area instead of running a continuous bead; this will keep the heat to a minimum, and less heat equals less warpage. Next is to apply the initial coat of filler as smooth as possible; the smoother the base, the less you will have to sand, and nobody likes to sand. Thirdly, learn to mix and spray primer and paint. Last but not least, you need all the right tools and equipment. We don't care how well you can weld - if you don't have a long block, you'll never get the area straight. So you can go out and buy all the tools or pay the professionals. Either way, get to customizing your truck.

| smooth A Dime chevrolet S10

Back in the May issue, in the story titled "Silverado Styling Staples," we reported how Drew Brothers Customs (DBC) in Arizona tackled some of the more common modifications, such as shaving, painting, and swapping out body parts. The story focused on a fullsize GM truck in the beginning phases of a mild custom build. We say "mild" because other than the shaved tailgate handle, the truck was customized with mainly bolt-on GM parts. Since this is our S-10 Special, we will dive deeper into the custom realm by getting into shaving all the handles, adding door solenoids, and molding in the steel roll pan. These are the kinds of modifications that have almost become standard in the S-10 class. S-10's are usually used as a guinea pig because they are an entry-level truck that, with some good searching, can be bought for a steal. All we have to say is, Thank goodness for that. If everything cost twenty of thirty grand, not many people would be cutting them up.

The parts list for this story is pretty short, consisting of a door kit from AutoLoc and a steel roll pan from AIM. Other than that, it's all about patience and talent. For the latter, we looked to the brothers Drew, the self-proclaimed merchants of cool, and Scott Deheart. Scott is one of many experienced guys out there slinging mud in the hot Arizona weather while Rob and Rich Drew chow down at the waffle house. This S-10 we will be following along with happens to be Scott's personal ride; we were lucky enough to catch him the last time we were in Arizona and asked him to wait for us.

We watched as Scott deleted all the exterior handles on his Dime using every bit of patience he had to keep the stuff from warping. There are a few key points to a nice shave job. One is to get the patch panel in with the least amount of warpage to the metal. That means taking your time and tack-welding the area instead of running a continuous bead; this will keep the heat to a minimum, and less heat equals less warpage. Next is to apply the initial coat of filler as smooth as possible; the smoother the base, the less you will have to sand, and nobody likes to sand. Thirdly, learn to mix and spray primer and paint. Last but not least, you need all the right tools and equipment. We don't care how well you can weld - if you don't have a long block, you'll never get the area straight. So you can go out and buy all the tools or pay the professionals. Either way, get to customizing your truck.

| smooth A Dime chevrolet S10

Back in the May issue, in the story titled "Silverado Styling Staples," we reported how Drew Brothers Customs (DBC) in Arizona tackled some of the more common modifications, such as shaving, painting, and swapping out body parts. The story focused on a fullsize GM truck in the beginning phases of a mild custom build. We say "mild" because other than the shaved tailgate handle, the truck was customized with mainly bolt-on GM parts. Since this is our S-10 Special, we will dive deeper into the custom realm by getting into shaving all the handles, adding door solenoids, and molding in the steel roll pan. These are the kinds of modifications that have almost become standard in the S-10 class. S-10's are usually used as a guinea pig because they are an entry-level truck that, with some good searching, can be bought for a steal. All we have to say is, Thank goodness for that. If everything cost twenty of thirty grand, not many people would be cutting them up.

The parts list for this story is pretty short, consisting of a door kit from AutoLoc and a steel roll pan from AIM. Other than that, it's all about patience and talent. For the latter, we looked to the brothers Drew, the self-proclaimed merchants of cool, and Scott Deheart. Scott is one of many experienced guys out there slinging mud in the hot Arizona weather while Rob and Rich Drew chow down at the waffle house. This S-10 we will be following along with happens to be Scott's personal ride; we were lucky enough to catch him the last time we were in Arizona and asked him to wait for us.

We watched as Scott deleted all the exterior handles on his Dime using every bit of patience he had to keep the stuff from warping. There are a few key points to a nice shave job. One is to get the patch panel in with the least amount of warpage to the metal. That means taking your time and tack-welding the area instead of running a continuous bead; this will keep the heat to a minimum, and less heat equals less warpage. Next is to apply the initial coat of filler as smooth as possible; the smoother the base, the less you will have to sand, and nobody likes to sand. Thirdly, learn to mix and spray primer and paint. Last but not least, you need all the right tools and equipment. We don't care how well you can weld - if you don't have a long block, you'll never get the area straight. So you can go out and buy all the tools or pay the professionals. Either way, get to customizing your truck.