| diesel Electronic Communications banks Tuner

The modern diesel engine is much more complicated than a purely mechanical diesel. It uses multiple sensors in the drivetrain to gather information that's sent to the engine computer, which controls all reactions to this information based on the driver's input. To squeeze more power out of the Cummins, Duramax, and Power Stroke engines, the aftermarket alters these electronic communications to maximize the horsepower and torque of the stock engines. There's plenty of easy power to be gained because the engines are built strong enough to handle much more torque than the factory settings, warranty, and emissions laws allow.

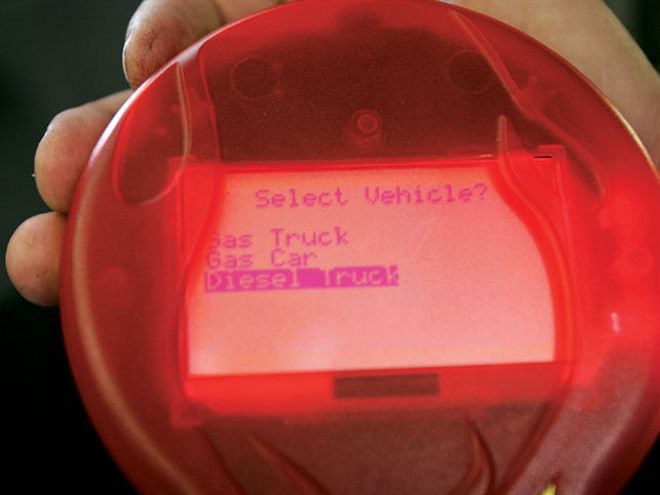

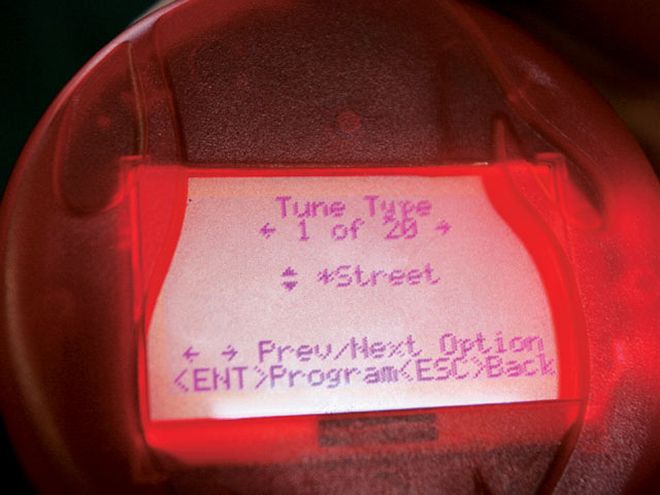

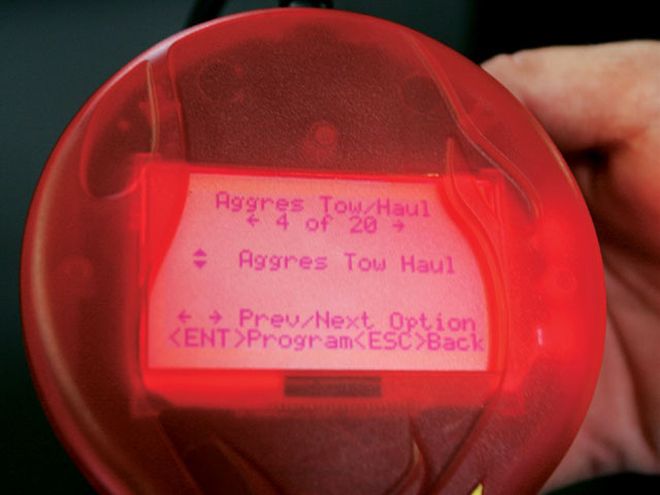

| Programmers and boxes offer various levels of control-from a simple multiposition switch or LED display to touchscreen controls-and even the ability to hack into the factory engine and transmission computers.

Stock Engine ComputerIt's true, the factory computer settings offer very conservative power levels because the OEM engineers are under many constraints that don't apply to aftermarket companies. In addition to building power, the programming inside the electronic control unit (ECU) must take several other things into account so your truck will idle smoothly, never smoke (even at wide-open throttle), and get good mpg numbers.

That's not easy, so power is sacrificed at the factory so every truck will work just as the engineers expect every time you turn the key for more than 100,000 miles. That's why multiple sensors in the drivetrain are used to constantly feed information to the ECU, which decides how to react and stay within the manufacturer specifications. Here are some of the main readings that are used by your truck's computer:

AirflowDiesel engines don't use an air throttle (except for the new EGR-equipped engines), so the ECU uses a manifold absolute pressure (MAP) sensor-and in some cases, a mass airflow sensor (MAF)-to determine engine load by measuring the density, rate, and mass of air flowing into the intake manifold at a particular rpm. This tells the computer how much fuel can be injected for an air/fuel ratio that will lead to the preferred type of combustion. A perfect combination where all the oxygen and fuel will be burned is called a stoichiometric mix, but the fueling used to achieve this greenhouse- and mpg-friendly type of combustion does not create as much power as a more fuel-rich mixture would inside the same engine.

| diesel Electronic Communications power Puck

FuelingSince the factory computer settings are concerned, first and foremost, with fuel-system durability and achieving a clean-burning combustion, the fueling system is not forced to perform up to its full potential. Much like purely mechanical injection pumps, electronic systems can be turned up to unlock horsepower that's not available when the stock programming is in control. Based on information from the sensor, the ECU will tell the injection pump to deliver fuel to the rail(s) connected to the injectors, which emit a burst of fuel (pulse) for a certain amount of time (pulse width) during a certain point in the combustion cycle (timing). With common-rail systems ('03-and-later Dodge, 6.4L Ford Power Stroke, GM Duramax), the fuel in the rail(s) is already pressurized to at least 23,000 psi when the engine is under full load, but this can be easily upped to 29,000 psi before seals in the stock injection pump will fail. The manufacturers prefer to stay well under that limit, so an injection pulse at a stock rail pressure will contain less fuel than a pulse of the same width when the rail has extra pressure.

Crankshaft RPM/Camshaft PositionTo determine the best time to inject fuel, the engine computer needs to know when the valves are open and where the cylinders are positioned. Crankshaft and camshaft position sensors in the engine send this information to the ECU, where they are added into its other calculations.

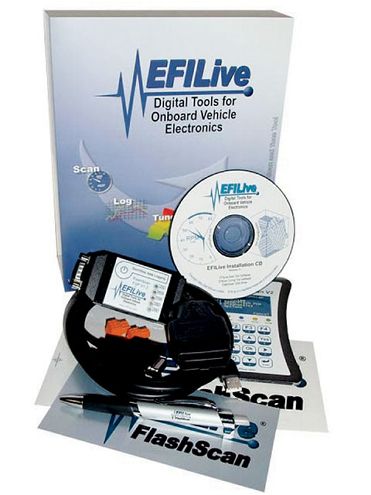

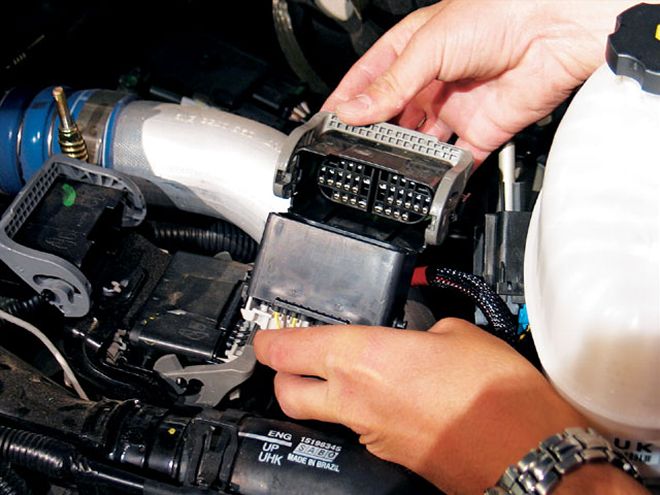

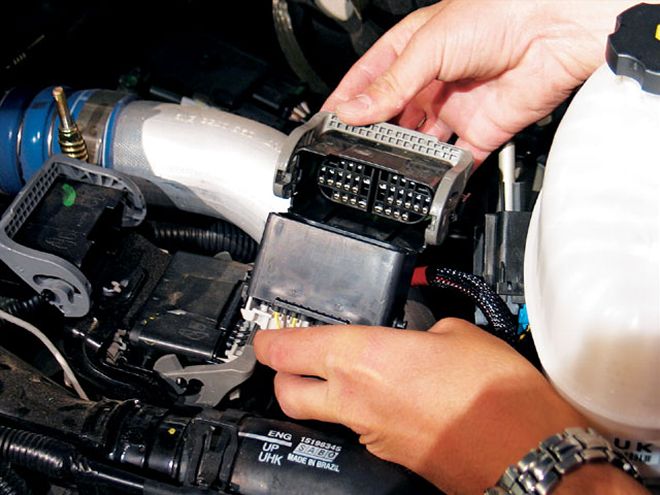

| diesel Electronic Communications efi Live Program

Throttle PositionOf course, the truck wants to know how you would like it to perform. You are the boss in this relationship, after all. When you mash on the accelerator pedal, the throttle-position sensor tells the ECU what you have done, uses the information it's constantly reading, and makes a calculation based on your input. With the factory settings in use, the ECU will attempt to perform to your expectations while staying within preset limits designed to protect the engine and transmission.

Transmission Input/OutputBy reading the speed of the input and output shafts of the transmission, the ECU can determine how much the transmission is slipping and adjust power output. The computer also uses the information so it knows when to de-fuel in between shifts and when the lockup torque converter engages to reduce the risk of damage.

Engine and Transmission TemperaturesIn addition to reading inputs from the transmission, the ECU monitors engine and transmission-fluid temperatures. This information also affects how the engine operates.

| diesel Electronic Communications programmers

EGT and DPF BackpressureThe new '07-emissions engines (6.4L Power Stroke, 6.7L Cummins, Duramax LMM) have a lot more information to read. Backpressure sensors are mounted before and after the diesel particulate filter (DPF) so the ECU can determine when it is packed with soot, which puts the engine into regeneration mode. [Editor's note: Exhaust-backpressure sensors can also be used to control variable-geometry turbochargers.] This operation increases mass airflow and fueling until a specific exhaust-gas temperature (EGT) is reached that can burn off the trapped particles. The 6.4L Power Stroke uses a pyrometer to measure the temperature of the exhaust, which can be very helpful information for the engine computer to use while making calculations.

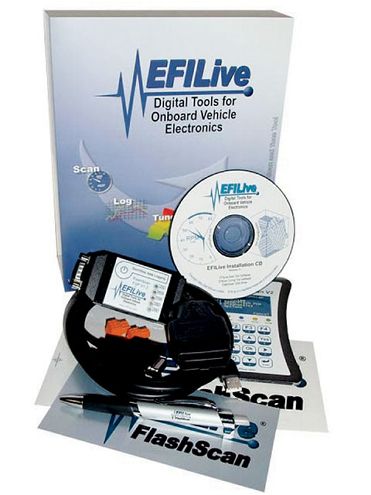

ProgrammerA programmer is a device that downloads custom tunes (programs) into the engine computer through the assembly-line data link (ALDL) port under the dash. It installs programs designed to build more power and torque by using more aggressive fueling and disarming factory preset limits in favor of custom ones. The ECU still receives the same information from the drivetrain, but the new programs can react with power output as the main objective (instead of emissions, driveability, and fuel consumption). With so much information available, a programmer can make complex decisions that affect the engine and transmission simultaneously-along with anything else operated by the ECU. This is why a programmer can be a very powerful tool. Some even allow you to log engine information during dyno runs, sled pulls, and drag races so it can be used to perfect your combination.

| Unlike a programmer that downloads tuning programs into the factory computer, a box (also called a module) is plugged in between the engine sensors and the ECU. It alters information so the engine computer will react with extra power output.

BoxA module or box controls power output by intercepting information from various engine and transmission sensors and sending altered signals (you could call it lying) to the ECU. Some also grab engine-computer output signals and replace them with data that will increase fueling to unlock power and operate the transmission so it can handle the extra torque.

Stacking Programmers and BoxesSome people achieve incredible power output by "stacking" a box on a truck that has been loaded with high-performance tunes. This is because the box will lie to the ECU, so the tune inside the computer will be reacting to altered information, which can kick up the fueling even more than either one working by itself. Some companies offer both a programmer and box designed to work together.

Programmer/Box Features to Look ForProgrammers and boxes offer many of the same features. Here are some of the most important to look for when you are shopping for more power:

| diesel Electronic Communications box

EGT limiterWith large amounts of fuel pumping through the engine, the exhaust is going to quickly heat up, especially if you are running the stock exhaust. Many tuners can limit the amount of fuel delivered once an exhaust temperature of around 1,250 degrees F is reached. This is very important because serious engine damage can result at a higher EGT. Installing a pyrometer will let you know when the EGT is too high, but it's best to have an electronic watchdog at work.

| diesel Electronic Communications wires

Transmission controlsWith more than stock power output, your automatic transmission will need to operate differently, or it will not have a long life. Some programmers and boxes have the ability to control the transmission shift points, hydraulic line pressure, and will even de-fuel the engine to reduce torque in between shifts and when the torque converter locks up. Separate transmission-control boxes are also sold.

Trouble-Code Reader And EraserIt can't hurt to know what a check-engine light means, and your chances of seeing one increase as soon as you begin upgrading the engine. There is lots of information to be obtained from diagnostic trouble codes (DTC), plus, you'll need to remove evidence of thrown codes before any warranty work is done.

Data LoggingBy recording information produced by the engine and transmission sensors, a data-logging programmer or box can reveal how the engine reacts to the tunes you install. This can be used to modify your tuning to match the needs of the engine.

Custom programmingWhile most boxes and programmers come with preset horsepower levels, some allow you to create custom tunes. This can be helpful in the quest for maximum power and should give you the flexibility to upgrade components like the turbo and injectors while maintaining tight control of the engine and transmission operations.

DisplayDisplays range from those with small two-color screens to full-color touchscreen units. They can provide instant feedback about engine conditions and be used as an interface to change tuning settings on the fly while you are driving.

| diesel Electronic Communications stats

| diesel Electronic Communications display Unit

Even if the programmer/box you choose does not have a display, you need a way to watch your exhaust temperatures and other readings to avoid engine and transmission damage. At the very least, you'll need an EGT gauge to make sure temperatures don't go past 1,250 degrees F. Many companies offer display units that can work in conjunction with a programmer/box so fueling is dialed back when the EGT gets too high.

Quarter-mile and 0-60-mph timerA fun feature of some units is dragstrip simulation. Using information from the speed sensor, a programmer/box can calculate how long it takes your truck to run from 0-60 mph and to 1,320 feet.

During our gas-versus-diesel test, we watched as the Granatelli Motor Sports crew loaded a program into a Ford 6.0L ECU with a Fuego tuner. They then stacked their Big G box on top of that. The result was a bone-stock Super Duty that made nearly 500 hp at the wheels.

| diesel Electronic Communications banks Tuner

The modern diesel engine is much more complicated than a purely mechanical diesel. It uses multiple sensors in the drivetrain to gather information that's sent to the engine computer, which controls all reactions to this information based on the driver's input. To squeeze more power out of the Cummins, Duramax, and Power Stroke engines, the aftermarket alters these electronic communications to maximize the horsepower and torque of the stock engines. There's plenty of easy power to be gained because the engines are built strong enough to handle much more torque than the factory settings, warranty, and emissions laws allow.

| diesel Electronic Communications banks Tuner

The modern diesel engine is much more complicated than a purely mechanical diesel. It uses multiple sensors in the drivetrain to gather information that's sent to the engine computer, which controls all reactions to this information based on the driver's input. To squeeze more power out of the Cummins, Duramax, and Power Stroke engines, the aftermarket alters these electronic communications to maximize the horsepower and torque of the stock engines. There's plenty of easy power to be gained because the engines are built strong enough to handle much more torque than the factory settings, warranty, and emissions laws allow.

| Programmers and boxes offer various levels of control-from a simple multiposition switch or LED display to touchscreen controls-and even the ability to hack into the factory engine and transmission computers.

Stock Engine Computer

| Programmers and boxes offer various levels of control-from a simple multiposition switch or LED display to touchscreen controls-and even the ability to hack into the factory engine and transmission computers.

Stock Engine Computer | diesel Electronic Communications power Puck

Fueling

| diesel Electronic Communications power Puck

Fueling | diesel Electronic Communications efi Live Program

Throttle Position

| diesel Electronic Communications efi Live Program

Throttle Position | diesel Electronic Communications programmers

EGT and DPF Backpressure

| diesel Electronic Communications programmers

EGT and DPF Backpressure | Unlike a programmer that downloads tuning programs into the factory computer, a box (also called a module) is plugged in between the engine sensors and the ECU. It alters information so the engine computer will react with extra power output.

Box

| Unlike a programmer that downloads tuning programs into the factory computer, a box (also called a module) is plugged in between the engine sensors and the ECU. It alters information so the engine computer will react with extra power output.

Box | diesel Electronic Communications box

EGT limiter

| diesel Electronic Communications box

EGT limiter | diesel Electronic Communications wires

Transmission controls

| diesel Electronic Communications wires

Transmission controls

| diesel Electronic Communications stats

| diesel Electronic Communications stats

| diesel Electronic Communications display Unit

Even if the programmer/box you choose does not have a display, you need a way to watch your exhaust temperatures and other readings to avoid engine and transmission damage. At the very least, you'll need an EGT gauge to make sure temperatures don't go past 1,250 degrees F. Many companies offer display units that can work in conjunction with a programmer/box so fueling is dialed back when the EGT gets too high.

Quarter-mile and 0-60-mph timer

| diesel Electronic Communications display Unit

Even if the programmer/box you choose does not have a display, you need a way to watch your exhaust temperatures and other readings to avoid engine and transmission damage. At the very least, you'll need an EGT gauge to make sure temperatures don't go past 1,250 degrees F. Many companies offer display units that can work in conjunction with a programmer/box so fueling is dialed back when the EGT gets too high.

Quarter-mile and 0-60-mph timer