If you've never had any type of onboard air system, you don't know what you're missing. And that's probably a good thing because you would've kicked yourself years ago for not having it if you'd realized how useful it'd be to you. Pressurized air can be used for air-driven tools, to fill up tires, run air lockers, fill airbags, for compressed air to blow things off, and even to run air-powered margarita mixers. It will seat a tire if you blow a bead and be your boon when you're stuck in the middle of nowhere.

| air Compressor Basics maxAir Air Compressor

But you have a few options of what type of air system to run, how to run it, and what accessories will make accessing your available air easiest. It'll take some brain time, but you can come up with some pretty trick air systems. We've seen guys running under-bed tanks with air couplers coming out the front and rear, an extra line to run a pneumatic locker switch, plus a hard line run to an air-driven blender.

ELECTRIC AIR COMPRESSORS

Electrically driven air compressors are a great way to get some onboard air without too much modification. They can be placed in almost any location and run to air tanks that will give a reserve for using air tools, filling airbags, or any other type of high-demand chore.

The 12-volt air compressors are nice for a number of reasons. They run off 12 volts, so you can use one on almost any vehicle made, and heavy-duty ones have a 100 percent duty cycle, which means you can just keep using them as long as you need. This MaxAir 4.0 unit comes with a stainless leader hose to run to an air tank, has an air output of 4.0 cfm at 0 psi, and requires no maintenance-not even oiling, because it has a piston sheathed in a Teflon coating. The compressor will put out a maximum of 150 psi, but this is not as important as the cubic feet per minute that it displaces. Example: a 3-gallon air tank filled to 150 psi will barely inflate one 35-inch tire, but a larger air tank, even sitting at a lower pressure, will have enough volume to fill the tire with some extra air to spare. Remember this when scouting for a new compressor: cfm is more important than psi!

The biggest drawback to an electrically driven air compressor? The amperage. At only 35 psi, the MaxAir will be drawing 30 amps from your battery. Step that up to 100 psi, and you're grabbing 46 amps from your electrical system and 60 amps at 150 psi! That's not even that bad compared to some other electric air compressors that will suck as much as 150 amps while running. This is enough to cause a lesser battery some serious issues, so make sure you have a heavy-duty battery (preferably a deep-cycle, sealed one) and your engine running and alternator charging, if possible.

| air Compressor Basics air Filtering Hose

There are two important aspects to look at when buying an electric air compressor. One being that it has some type of air-filtering element because you're going to be off-road, right? The other being that the compressor has a 100 percent duty cycle. This means that the compressor will run nonstop as long as you want. Anything less than 100 percent means that you'll be stopping to let the compressor cool down before you're likely done with your work.

CO2 TANKS

Carbon dioxide tanks have become very popular to have in vehicles over the last decade or so. They've been around for much longer than that, but the idea of having a portable air tank that you can carry to any job has become very appealing. They typically come in 5- or 10-pound tanks, and can fill more tires than your patience would handle. This unit from Powertank is just about the best you can get when it comes to CO2 tanks. It's typically a bit more expensive than other tanks, but it comes with an extremely nice regulator showing tank pressure and line pressure along with a coiled air hose and tire inflator sporting a built-in pressure gauge.

The real advantages of this type of air system are that you do not have to wait for some compressor to air up, there are really no moving parts, and it can be pulled out of your truck and taken far away from any type of power connection.

Why carbon dioxide instead of air or nitrogen? CO2 is a much denser gas than typical air or nitrogen and is stored in the bottle in a liquid state under a massive amount of pressure. For an air or nitrogen tank to endure as long as a CO2 tank would, it would have to be at least three times the size.

The downside of CO2 tanks? When you run out of juice, you'll have to take the tank to a CO2 refilling station. The regulators will also freeze (cold) under constant use, requiring you to sometimes stop running your power tools and let things warm back up.

ENGINE-DRIVEN COMPRESSORS

As far as compressors go, you really cannot beat the volume or pressure put out by an engine-driven air compressor. This type of compressor can be bought or even built from an old A/C compressor and runs off your serpentine or V-belt pulley drive system on your engine. It puts no amperage load on your battery, and a unit like the York unit from Kilby Enterprises can exceed 250 psi if so desired (your air tools, lockers, and air tanks will not handle this much pressure). All engine-driven compressors we've ever come across are 100 percent duty cycle by nature. Since they are run right off the engine, the amount of air pushed out is directly proportional to how fast the engine is spinning. At idle, an engine-driven air compressor will put out less than an electric compressor, but once the rpm (of the engine) are ramped up, so is the compressor air output. At 100 psi, a unit like the York 210 will put out anywhere from 3 1/2 to 8 cfm, depending on your engine speed. No onboard electric air compressor we can think of will do that.

| air Compressor Basics kilby Enterprises York Unit

The downsides to having an engine power your compressor? They will require modifying your engine's pulley drive system, plus you will need to have the engine running when you're trying to use it. If you can't start your engine, then you can't run your compressor.

AIR ACCESSORIES

Air Tank Think of an air tank as a surplus or reserve for your air system. An air tank will fill up via the air compressor and give you a pressurized volume of air that you do not have to wait for the air compressor to pump out. For some duties (not small ones like engaging air lockers) you will use up the surplus air in the tank before the compressor has a chance to refill it. At that time, you are then running straight off the compressor to power whatever you are powering.

The new 3-gallon air tank from 4WD Products has four 3/8-inch NPT ports on the side, three on the end of the tank, and one port on the bottom.

| air Compressor Basics NPT Ports

If you need more ports than that, then maybe you should be running two of these tanks together.

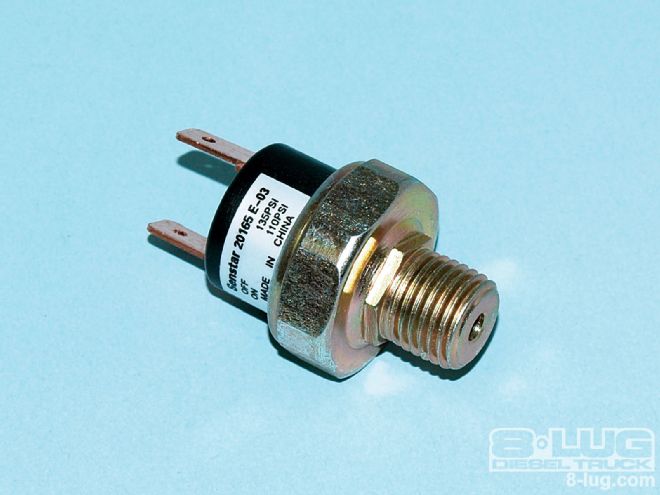

Pressure Switch Whenever you're running an air tank with an air compressor, you'll need to use a pressure switch that will shut off the air compressor once it gets to a certain pressure. This will help with any unfortunate happenstances like compressors melting down, breaking, or worse. Make sure that the pressure switch has a lower shut-off pressure than the maximum air pressure of the air compressor.

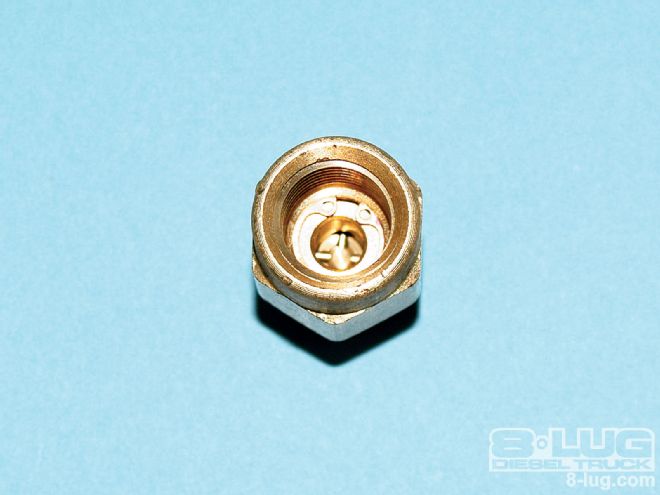

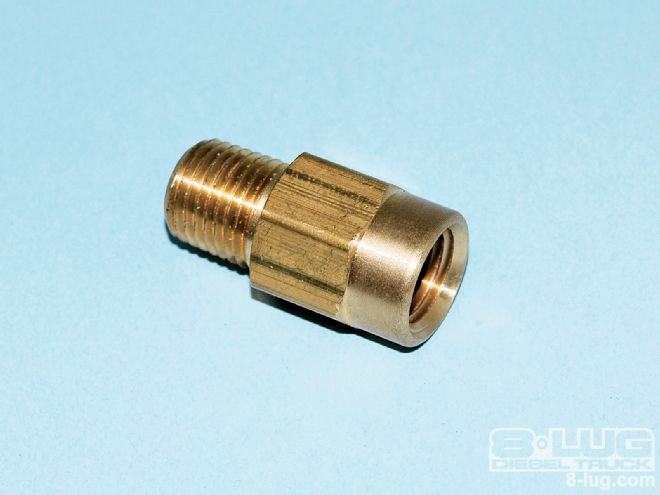

Check Valve You should also have a check valve whenever running an air compressor and air tank together. This is basically a one-way valve that allows air to flow one way through it, but not the other (in opposite direction). This will prevent any feedback in the line and will hold the tank at pressure.

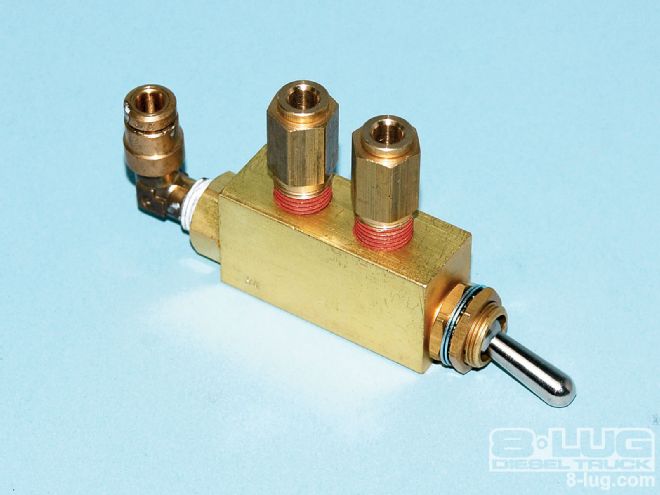

Distribution Block A 6+2 universal manifold from Powertank will allow you to split your air system from just one line to multiple lines. Maybe you have more than one air tank, two compressors (one for backup), or want to run everything off your Powertank. You'll need a distribution block to plumb all the lines together. This particular one from Powertank has six 1/4-inch NPT ports and two 3/8-inch NPT ports.

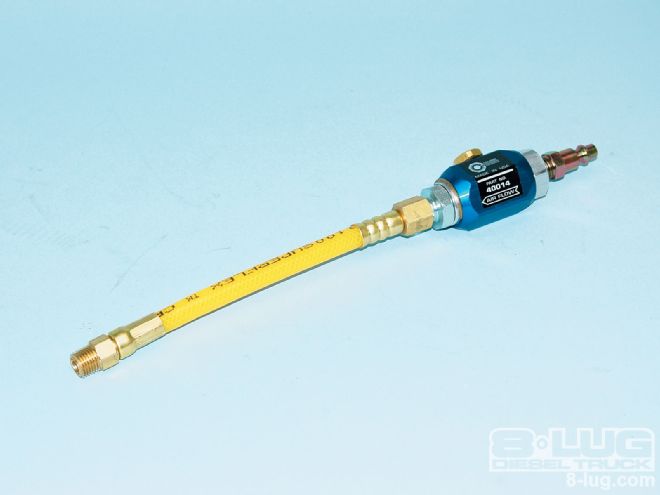

Air Tool Oiler The safe rule of thumb is to oil an air tool every time you use it. Do you do that? Nah, we don't either. But oiling an air tool will provide a much longer life with better reliability. Powertank has an inline air tool oiler that automatically puts oil into an air tool as it is used.

Pneumatic Switch (like for an ARB!) For the ultimate in reliability and performance, some individuals choose to cut out any electrical mumbo jumbo from their ARB Air Locker systems and, instead, just run fully pneumatic switches. This is a great idea as long as you do it right. An air toggle switch from Powertank has fittings (for the 5mm blue ARB line) for an air line from the compressor to the air locker and one for exhaust (air exhalation when you shut the locker off). Powertank recommends that you run a line to the exhaust fitting and run it to the outside of your cab so you do not get a gear oil smell when the locker blows off.

Super Couplers Super couplers from Powertank are worth every penny you spend over the price of a typical air coupler. The super couplers accept both automotive and industrial air fittings and have a black sliding sleeve that acts as an on/off for air pressure. With the sleeve slid down, no air will flow past the coupler. Slide the coupler up, and air will flow freely. Pictured on the far right (from top to bottom) are the male super coupler with black sleeve down (air off), the female super coupler with black sleeve down, and a female coupler with the black sleeve up (air on).

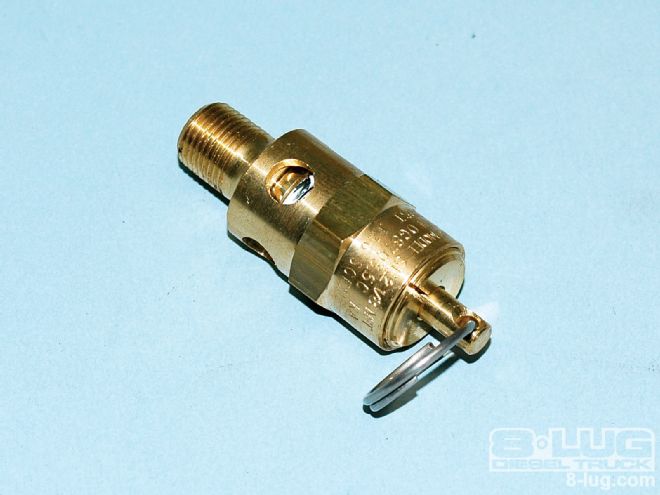

Pressure Release Valve It's important to run a pressure release valve inline to your ARB Air Locker if you are using pneumatic switches. The valve will blow off pressure at 125 psi, keeping your ARB Air Locker safe. Running a straight line to the ARB (without a blowoff valve) could potentially allow the pressure in the air locker to exceed 125 psi, subsequently damaging the air locker.