"Topping Off Our 383 Stroker Build With Edelbrock E-Street Self-Learning EFI"After calling up Edelbrock and ordering a base E-Street EFI system (PN: 3600), we needed to find a shop that could install the system and run our build on an engine dyno for the first time. Superior Automotive Engineering, in Placentia, California, offered to help and even said they would run the engine first with a carburetor for comparative purposes. The guys at Superior are extremely knowledgeable about all kinds of engine work, from thousand-horsepower race motors to simple street builds, so we knew they could get us all dialed in. Follow along to see how our 383 fared on the engine dyno, both with a carburetor and with the new Edelbrock EFI.

| 1. After we dropped the engine off at Superior, the guys promptly installed the flexplate from our SCAT rotating assembly and bolted the block to the engine dyno stand. An oil filter was also installed in preparation for the next step.

| 1. After we dropped the engine off at Superior, the guys promptly installed the flexplate from our SCAT rotating assembly and bolted the block to the engine dyno stand. An oil filter was also installed in preparation for the next step.

| 8. After bolting on Superior’s set of long-tube headers, the fuel line, coolant sensor, and O2 sensors were hooked up, and the engine was ready to start up.

| 8. After bolting on Superior’s set of long-tube headers, the fuel line, coolant sensor, and O2 sensors were hooked up, and the engine was ready to start up.

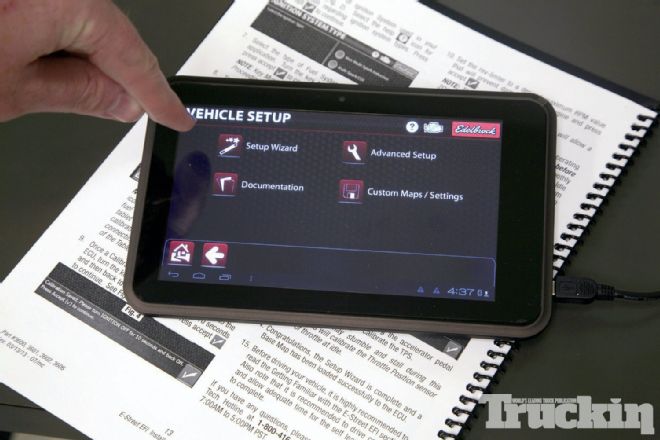

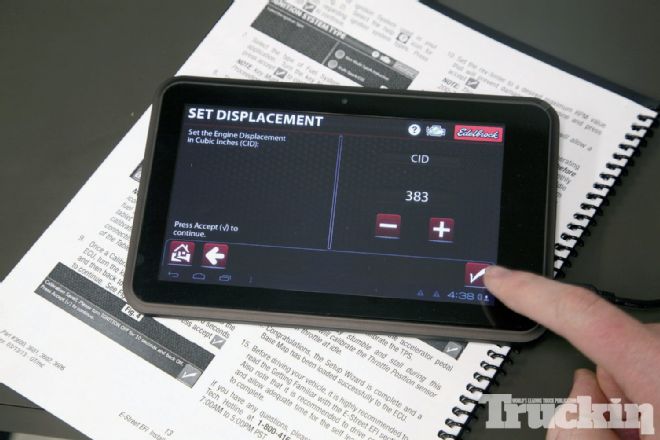

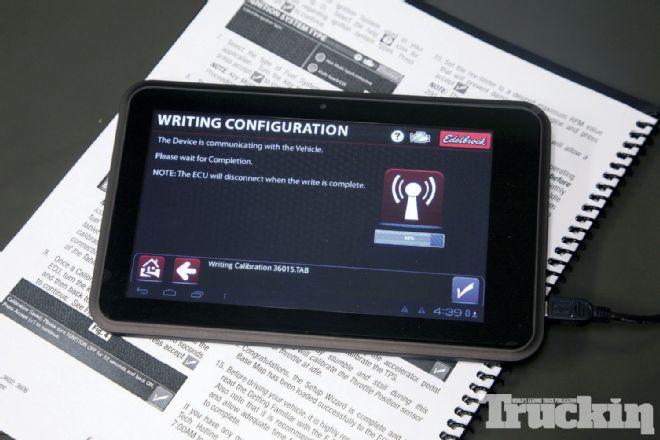

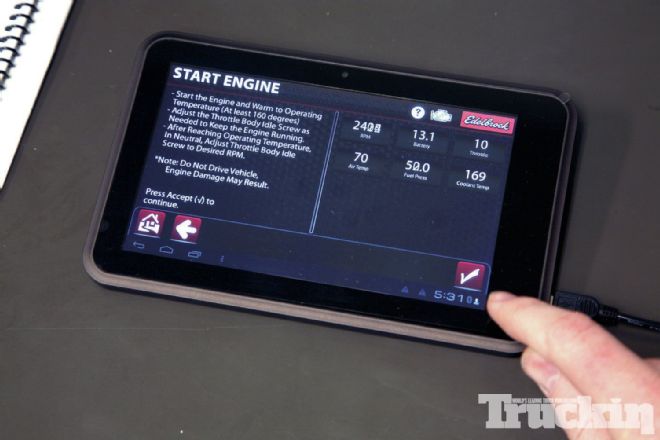

| 15. This little red ECU box is the brains behind the EFI’s operation, and it will connect wirelessly via Bluetooth to the included 7-inch touchscreen tablet. We plugged it into the wiring harness, and connected the harness to the dyno’s ignition circuit for a 12V switched power source.

| 15. This little red ECU box is the brains behind the EFI’s operation, and it will connect wirelessly via Bluetooth to the included 7-inch touchscreen tablet. We plugged it into the wiring harness, and connected the harness to the dyno’s ignition circuit for a 12V switched power source.

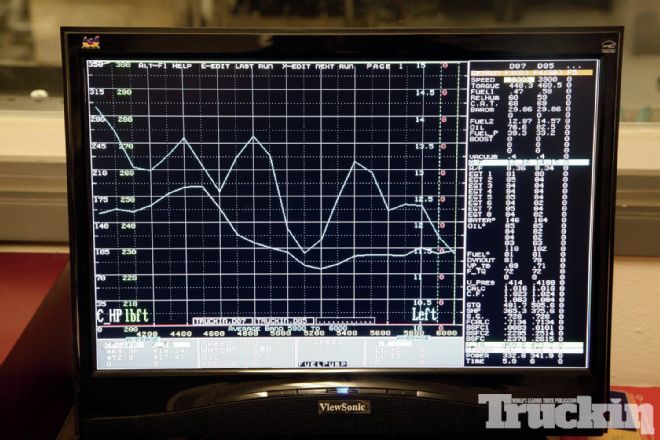

| 22. So, we know the Edelbrock E-Street EFI is vastly more high tech than a carburetor, but what about the all-important power gains? After a few quick runs to let the self-learning system tune itself, our 383 stroker made 470 hp at 5,800 rpm and 477 lb-ft of torque at 4,400 rpm. That’s a total gain of 22 hp and 20 lb-ft of torque, as well as a huge amount more area under the curve (meaning more usable power from low RPM to high RPM). On top of that, we’ll be able to get better fuel economy and reliability than a carbureted setup, which is ideal for a daily driven performance truck.

| 22. So, we know the Edelbrock E-Street EFI is vastly more high tech than a carburetor, but what about the all-important power gains? After a few quick runs to let the self-learning system tune itself, our 383 stroker made 470 hp at 5,800 rpm and 477 lb-ft of torque at 4,400 rpm. That’s a total gain of 22 hp and 20 lb-ft of torque, as well as a huge amount more area under the curve (meaning more usable power from low RPM to high RPM). On top of that, we’ll be able to get better fuel economy and reliability than a carbureted setup, which is ideal for a daily driven performance truck.