Back in February 2009, we rescued this '87 Ford F-250 from a one-way trip to the junkyard. We got its 6.9L IDI diesel engine, ZF five-speed transmission, and twin I-beam, two-wheel-drive suspension resurrected with the items listed on the next page. This month we've modified the ATS-turbocharged engine with a Snow Performance Diesel Stage 3 MPG-MAX water-methanol injection system.

| 1987 Ford F250 driver Side View

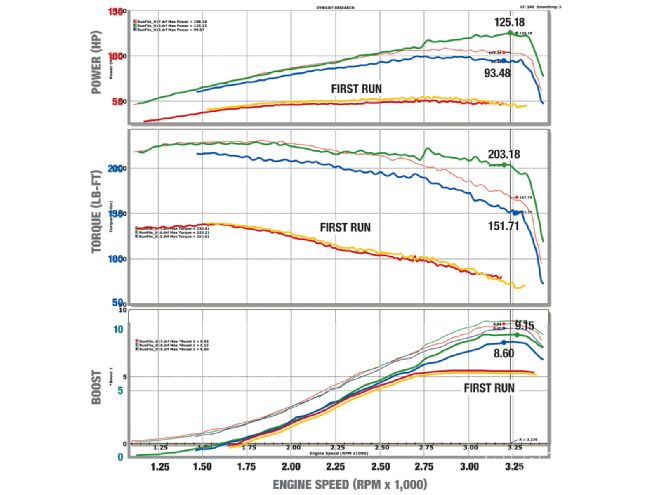

This Snow Performance kit was originally designed for the 7.3L Power Stroke (PN#50005) but we found it to be fairly universal, and it worked on our IDI without any problems. This kit provides a way to monitor both boost and EGT without gauges (which we didn't have before), since the electronic controller monitors and displays both figures. At the same time, we now have a way to control intake and exhaust temperature without adding an intercooler. On the dyno, the water-methanol system gave us a solid 25 percent horsepower increase. We also noted a 2- to 3-mpg gain and the engine's exhaust smoke cleared up.

First, we installed the 7-gallon water and methanol reservoir by drilling and snipping four 1 x 1/2-inch holes in the bed of our '87 F-250. Then we cut the hooks off two 1-inch ratchet straps in order to secure it. Next, we drilled an 11/32-inch hole, installed a grommet, and ran the high-pressure tubing from the tank to the pump. Lastly, a reducer bushing was threaded into the tank and a 90-degree quick-connect fitting was threaded onto it. We made sure to seal the threads with the provided E6000 methanol-use-approved sealant (do not use Teflon). In order to connect the tubing to the quick-connect fittings, all we needed to do was make a square cut and push the tubing 1/2 inch into the fitting. To disconnect the hoses, we just gently pushed in the collar on the fitting and tugged on the tubing (it'll pop right on and off, with no sealant needed).

| 1987 Ford F250 water Methanol Reserve Tank

Snow Performance says to mount the pump on the frame, lower than the reservoir, and away from road debris. The pump can be mounted either vertically or horizontally. We unbolted the crossmember support and then drilled the holes. Make sure to create a solid ground and have weather-tight electrical connections.

| 1987 Ford F250 snow Performance Methanol Pump

This water-methanol injection system uses two stages of delivery to the engine controlled by these solenoids. Water-methanol from the pump (A) enters the first solenoid (B). Water-methanol then goes to a T-fitting (C) and then to the second solenoid (D). The red tube on the top left goes to the second stage injector (E) and the one below it (F) goes to the first stage injector. We used four M4-.7x10mm bolts, 24 #6 washers, and a piece of 1/2 x 1/8-inch steel to mount the solenoids. Each solenoid has two wires-one is a ground and the other goes to power-but it doesn't matter which goes where. The first solenoid connects to the white wire from the controller and red wire from the pump. The second solenoid connects to the green wire from the controller.

| 1987 Ford F250 water Methanol Injection System

The Snow Performance controller has two different main settings. The MPG mode references boost pressure, and the Tow mode uses boost and exhaust gas temperature to determine the water-methanol injection strategy. For our application, we chose the MPG mode and set the first stage to come on at 2 psi and max out by 6 psi. The second stage comes on at 6 psi. Button 1 (on the left) toggles through the different screens. Button 2 (on the right) allows you to make changes. If you hold in both buttons at the same time (pressing 2 first) and then release them, the injection system activates and deactivates-but you can still view the screens. We used a 10-amp Littelfuse Add-A-Circuit and the included switch on our fuse box to power up the controller, which also powers up the entire system.

| 1987 Ford F250 snow Performance Controller

PRICE LIST: STAGE ONE TO EIGHT

STAGE 1:

Original Investment, Feb. '09

$888

Including $300 for cost of truck

STAGE 2:

Getting it Running, May '09

$315

Glow plugs, fuel return line kit, autocross fee, and dyno testing

STAGE 3:

Adding a Turbo, Aug. '09

$2,616

ATS Aurora 2000 wastegated 7.3L turbo system, ATS exhaust system, and polyurethane body mounts

STAGE 4:

Suspension, Tires, Bearings, and Brakes, Oct. '09

$1,632

Calipers, pads, rotors, brake lines, 2-inch leveling kit, tires, tools, and shocks

STAGE 5:

Cooling System Rehab, March '10

$1,159

Radiators, cap, thermostat, block heater, hoses, and antifreeze

STAGE 6:

Engine Oil Centrifuge, June '10

$786

Centrifuge, fittings, hose, and air pump

STAGE 7:

140-Mile Commute, Aug. '10

$879

Sulastic springs, rear ABS valve, and Pioneer CD player with speakers

STAGE 8:

Snow Performance water-methanol injection system (#50005)

$1,004

1/8-inch plugs

$2

Littelfuse Add-A-Circuit (10-amp)

$9

24 #6 SAE washers

$1

4 M4-.7x16mm hex bolts

$3

1/8-inch x 1/2-inch x 36-inch steel

$5

38-inch passenger-side ground cable

$9

48-inch driver-side ground cable

$10

Electrical tape

$3

4 gallons of Boost Juice

$30

1 gallon of distilled water

$1

Heet (methanol) 36 ounces

$6

Stage 8 total:

$1,083

PROJECT 300 GRAND TOTAL

$9,358