| 1987 Ford F250 Buildup left Rear Angle

Our Project 300 '87 Ford F-250 got its name from the dollar amount we initially paid for it. Its debut in the February '09 issue ("$300 Diesel") showed us towing our new project home, installing two Optima Yellow Top batteries, changing the fluids and filters, fixing the clutch pedal assembly with JB Weld, and adding a firewall reinforcement bracket. Those modifications got Project 300 up and running, but it wasn't quite ready for daily use. This month we will show you how we were able to make our $300 ride roadworthy and have fun with it at a local diesel club event. Here is what we had to do to get there.

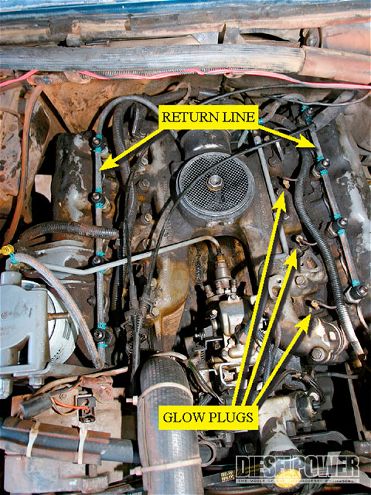

EngineThe first priority with this second wave of modifications was getting the engine running better. We knew the glow plugs were bad because we could hear the controller clicking when we switched on the ignition and it wouldn't start when it was cold. The '87 model year was kind of a sweet-spot year for the F-250. Not only did we get the ZF five-speed transmission, but our truck also came with the improved solid-state glow plug controller. The easiest way to tell what kind of controller you have is to look at the glow plugs. The old style has spade connectors, while the newer version uses bullet ends. The job of the controller is to regulate when the glow plugs get electricity.

Since the fuel injection lines run right over the top of some of the glow plugs, we decided it would be easier to install them when the fuel lines going from the injection pump to the injectors were off (although you don't have to remove them). The perfect opportunity arose when we discovered our return lines were leaking. To put an end to the leaks, we ordered a return line kit from Oregon Fuel Injection. The kit came with fabric-coated hose, O-rings, washers for the injectors, plastic caps, and spring clamps. In order to do the job, we removed the injector lines. We numbered them so they would be easier to reinstall. If we had to do it all over again, we'd use fuel system protection caps (T83T-9395-A) to eliminate the risk of getting crud in the removed lines.

With the engine running better, the next problem was the new alternator belt was flopping wildly just like the old one. To help the situation, we decided to re-route the belt. Instead of having the belt go around the crankshaft, water pump, and alternator, we got a shorter belt and just went from the water pump to the alternator. This setup is a little risky since it takes away the redundancy of having multiple belts going to the water pump. We found the part number for the belt on oilburners.net. We consider this a temporary fix, with the ultimate solution being a serpentine belt swap from a '92 to '94 7.3L IDI engine.

ElectricalWith the engine ready for the road, we had to get the rest of the truck up to speed. The turn signals didn't work. They worked before we took the dash out, so our first thought was we were going to have to take the dash out again in order to chase the short. As it turns out, the rear taillight pigtails were so packed with grease they would periodically short out. After a thorough cleansing with electrical cleaner, all the lights finally worked.

The next problem was our Optima batteries needed to be secured. We headed down to the local parts store and bought two Lynx battery hold-down kits (part LBHK) for $3.99 apiece. The top strap is made of rubber (an insulator), which will help isolate vibrations. This setup is just temporary. We'll be looking for something strong enough for racing in the future.

BodyWith the engine running better, our attention shifted to the body. First we measured diagonally across Project 300's engine bay to see if it was square. It was close, so we didn't need to do any major pulling on a frame rack. The passenger-side corner took the biggest hit. A slight tug with a rope attached to a Jeep pulled the radiator support back to its original position.

DP

Price List (Shipping and Handling Included)

Orignial Investment From Stage 1:'87 F-250 140,000-mile two-wheel-drive -

$300DMV registration (needed to get towed) -

$115200-mile tow home -

AAA membershipOptima Yellow Top Batteries -

$300Motor oil 10 quarts 15W-40 -

$20Transmission fluid 4 quarts -

$10Oil filter -

$11Fuel filter -

$16Air filter -

$11JB Weld -

$6Firewall reinforcement -

$17Fuel pump -

$32Alternator V-belt -

$11Large drip pan -

$10Two plastic buckets with lids (for bed storage) -

$15Spray paint (Rosewood Satin) -

$4Paint and rust stripper disc -

$10

Total $888

From Stage 2:Glow Plugs Bosch #80027 (8) -

$90Fuel return line kit -

$42Right (passenger) corner lamp -

$44Bench seat cover -

$10Heater Hose 19/32-inch -

$18Alternator V-belt (PN 17425) -

$17Spring-loaded hood hinge -

$15Front filler -

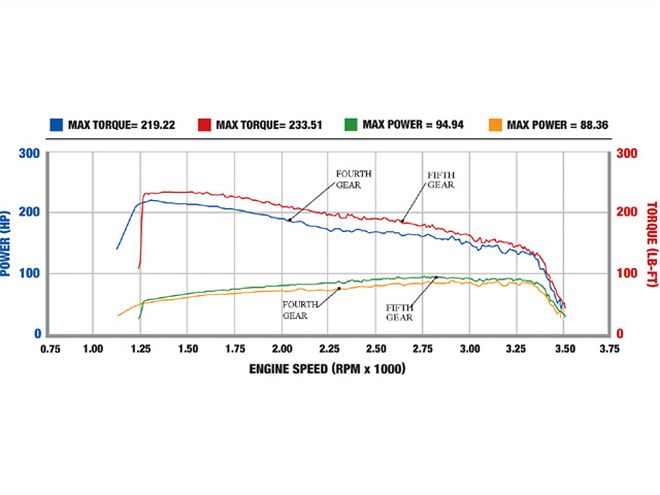

$30Dyno runs (2) -

$40Battery hold-downs (2) -

$7Autocross fee -

$2

Total $315

| 1987 Ford F250 Buildup left Rear Angle

Our Project 300 '87 Ford F-250 got its name from the dollar amount we initially paid for it. Its debut in the February '09 issue ("$300 Diesel") showed us towing our new project home, installing two Optima Yellow Top batteries, changing the fluids and filters, fixing the clutch pedal assembly with JB Weld, and adding a firewall reinforcement bracket. Those modifications got Project 300 up and running, but it wasn't quite ready for daily use. This month we will show you how we were able to make our $300 ride roadworthy and have fun with it at a local diesel club event. Here is what we had to do to get there.

Engine

| 1987 Ford F250 Buildup left Rear Angle

Our Project 300 '87 Ford F-250 got its name from the dollar amount we initially paid for it. Its debut in the February '09 issue ("$300 Diesel") showed us towing our new project home, installing two Optima Yellow Top batteries, changing the fluids and filters, fixing the clutch pedal assembly with JB Weld, and adding a firewall reinforcement bracket. Those modifications got Project 300 up and running, but it wasn't quite ready for daily use. This month we will show you how we were able to make our $300 ride roadworthy and have fun with it at a local diesel club event. Here is what we had to do to get there.

Engine