| BeforeThe first pass was only 15 mph, but after the bars were installed, the speed was cranked up to 40 mph, and we still had less lean.

In the past couple issues, we have been throwing parts on an ex-'bagged '94 Chevy in the attempts to turn it into a daily driveable G-machine. The first month, we lowered the truck with a Stylin' Concepts 2/4 kit that consisted of coil springs for the front and a shackle/hanger kit for the rear. We also mounted up the kick-ass rolling stock from Ultra Wheel and Nitto Tire. The rims are a Counter Pressure Cast one-piece construction 18x9-inch Hot Schotts with a 10mm offset. Surrounding the Schotts is a set of Nitto 295/45ZR18 NT-555s, which will give us a whole lot of traction, thanks to the fat contact patch and the soft compound. Next, we took a trip over to Energy Suspension to have all the soft factory bushings swapped out with performance-minded polyurethane bushings.

| AfterHere, you can see the major difference in the truck after the bars were installed. Not only does the truck corner much flatter but we could go through the contes at a much faster speed.

Energy's special formula Hyper-Flex performance polyurethane components feature a higher durometer (firmness) material that will last longer and deflect less to provide a solid base for our suspension. Now it's time for us to get rid of the excessive body roll in the truck and get this sucker to corner as flat as possible. Since this truck was an ex-'bagger, there were no sway bars to be found when we purchased it, so the body roll was beyond excessive. One name that is synonymous with the science of sway is Hotchkis Performance. The company has been improving the handing of almost every vehicle since 1993, and our truck is no exception, as the company has a front and rear bar kit just for it.

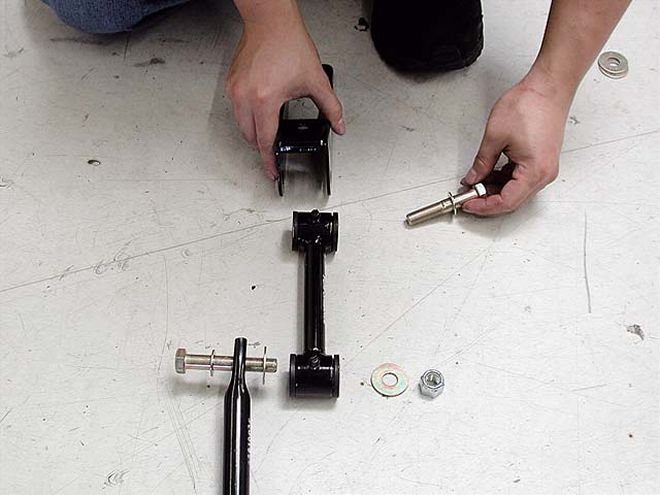

The 1-7/16-inch front Hotchkis bars feature lightweight hollow construction, while the 7/8-inch rears are a solid design. The kit includes greasable polyurethane bushings, endlinks, brackets, and all the necessary hardware to complete the install. The bars are powdercoated for durability, and tested and tuned to ensure the best performance possible. We drove to the Hotchkis facility in Santa Fe Springs, California, to have the crew install these bars, and so we could check out how the bars are made. That's right, they are made in-house.

Hollow vs. SolidThere are many advantages to using a tubular anti-roll bar rather than a solid bar. The foremost advantage is the weight reduction that can be achieved by using hollow technology. Second is design adjustability, because all you have to do is change the wall thickness of the material to give an incremental change in stiffness. There are many misconceptions floating around about the hollow bar designs. One major one is that a solid bar is stronger than a hollow one. This is only partially correct. If a solid bar and a hollow one of the same diameter are compared, then the solid bar is stiffer than the hollow version. By increasing the outer diameter of the hollow bar, and fine-tuning the wall thickness, you can yield the same performance while reducing weight. How many racing designers try to cut every ounce out of the chassis? They all do! Reducing weight acts like adding horsepower.

The chart displays the results of comparing a 1-inch solid bar to a 1-inch hollow bar with a 0.25-inch wall thickness. Compare the 1-inch solid directly to the 1-inch hollow bar. By removing a 1/2-inch hole from the center of the bar, the stiffness of the bar is reduced by only 6-1/2 percent. Anything less than a 10-percent change cannot be felt by most of the drivers out there. This results in a slight increase in stress by only 5.9 percent. (We assume all bars are manufactured using the same material and subjected to the same 1,000-pound load). Another thing to note when comparing these two bars is that the hollow bar weighs only 8.34 pounds, whereas the solid bar is 11.14 pounds. That's a weight reduction of 25 percent for this part, yet it only loses 5.9 percent stiffness.

Variable

1-Inch Solid

1 x 0.25" Hollow

1.062 x 0.188" Hollow

1.188 x 0.188"

Stiffness

333

312

350

429

%Increase

of Stiffness

-6.5

+5.5

+29

Stress

(KSI)

51

54

51

45

%Stress

Increase

+5.9

0

-12

Weight(lb.)

11.14

8.34

7.35

7.8

%Weight

Increase

-25

-34

-30

| BeforeThe first pass was only 15 mph, but after the bars were installed, the speed was cranked up to 40 mph, and we still had less lean.

In the past couple issues, we have been throwing parts on an ex-'bagged '94 Chevy in the attempts to turn it into a daily driveable G-machine. The first month, we lowered the truck with a Stylin' Concepts 2/4 kit that consisted of coil springs for the front and a shackle/hanger kit for the rear. We also mounted up the kick-ass rolling stock from Ultra Wheel and Nitto Tire. The rims are a Counter Pressure Cast one-piece construction 18x9-inch Hot Schotts with a 10mm offset. Surrounding the Schotts is a set of Nitto 295/45ZR18 NT-555s, which will give us a whole lot of traction, thanks to the fat contact patch and the soft compound. Next, we took a trip over to Energy Suspension to have all the soft factory bushings swapped out with performance-minded polyurethane bushings.

| BeforeThe first pass was only 15 mph, but after the bars were installed, the speed was cranked up to 40 mph, and we still had less lean.

In the past couple issues, we have been throwing parts on an ex-'bagged '94 Chevy in the attempts to turn it into a daily driveable G-machine. The first month, we lowered the truck with a Stylin' Concepts 2/4 kit that consisted of coil springs for the front and a shackle/hanger kit for the rear. We also mounted up the kick-ass rolling stock from Ultra Wheel and Nitto Tire. The rims are a Counter Pressure Cast one-piece construction 18x9-inch Hot Schotts with a 10mm offset. Surrounding the Schotts is a set of Nitto 295/45ZR18 NT-555s, which will give us a whole lot of traction, thanks to the fat contact patch and the soft compound. Next, we took a trip over to Energy Suspension to have all the soft factory bushings swapped out with performance-minded polyurethane bushings.  | AfterHere, you can see the major difference in the truck after the bars were installed. Not only does the truck corner much flatter but we could go through the contes at a much faster speed.

Energy's special formula Hyper-Flex performance polyurethane components feature a higher durometer (firmness) material that will last longer and deflect less to provide a solid base for our suspension. Now it's time for us to get rid of the excessive body roll in the truck and get this sucker to corner as flat as possible. Since this truck was an ex-'bagger, there were no sway bars to be found when we purchased it, so the body roll was beyond excessive. One name that is synonymous with the science of sway is Hotchkis Performance. The company has been improving the handing of almost every vehicle since 1993, and our truck is no exception, as the company has a front and rear bar kit just for it.

| AfterHere, you can see the major difference in the truck after the bars were installed. Not only does the truck corner much flatter but we could go through the contes at a much faster speed.

Energy's special formula Hyper-Flex performance polyurethane components feature a higher durometer (firmness) material that will last longer and deflect less to provide a solid base for our suspension. Now it's time for us to get rid of the excessive body roll in the truck and get this sucker to corner as flat as possible. Since this truck was an ex-'bagger, there were no sway bars to be found when we purchased it, so the body roll was beyond excessive. One name that is synonymous with the science of sway is Hotchkis Performance. The company has been improving the handing of almost every vehicle since 1993, and our truck is no exception, as the company has a front and rear bar kit just for it.