| Here is the Master Set from Energy Suspension, which as you can see is very complete, hence the name Master Set. It includes upper and lower control arm bushings, leaf spring bushings, sway bar bushings, endlinks, motor mounts, transmission mount, ball joint boots, and tie rod boots.

Last month, we launched a build to turn a stock '94 Chevrolet Truck into a daily driveable G-Machine. To bring you up to speed, we installed a DJM lowering kit that we got from Stylin' Concepts, which included 2-inch drop springs for the front and a 4-inch shackle/hanger kit for the rear. Those components lowered the truck's center of gravity and will make good use of the fat sticky rubber and strong wheels we bolted up. The wheels we used are Ultra Wheel's new Hot Schott in an 18x9-inch size with a 10mm offset. They are a Counter Pressure Cast one-piece construction that will provide plenty of rigidity, and the chrome finish will be easy to maintain. Surrounding the Schotts is a set of Nitto's 295/45ZR18 NT-555s, which will give us the fat contact patch we want for traction. And since all four tires are the same size, we can rotate them to prolong their life.

| We will install the motor mounts at a later date, but we still wanted to let you see them.

This month, we will move a little deeper and replace all the factory rubber bushings with a performance-minded set of polyurethane bushings from Energy Suspension. Unless you have been trapped in your garage for way too long, then you already know what the benefits are. But, just in case, we will go over them. There are two main purposes of the suspension bushings: One is to allow the pivot points to move and the second is to isolate and damp vibrations transferred from the road. The factory uses rubber because it does a great job at damping. And yes, it allows the pivots to move, but usually it's relatively soft and will deflect under heavy loads. When you turn a corner, the bushing is subjected to increased load, and if the bushing deflects, then a lot of things can change like caster, camber, and toe settings. Over time, this increased load can compress most rubber permanently, and such was the case of our '94. When we got the arms out, we could see the bolt hole was not centered in the bushing. Energy's special formula Hyper-Flex performance polyurethane components feature a higher durometer (firmness) material that will last longer and provide a solid base for our suspension.

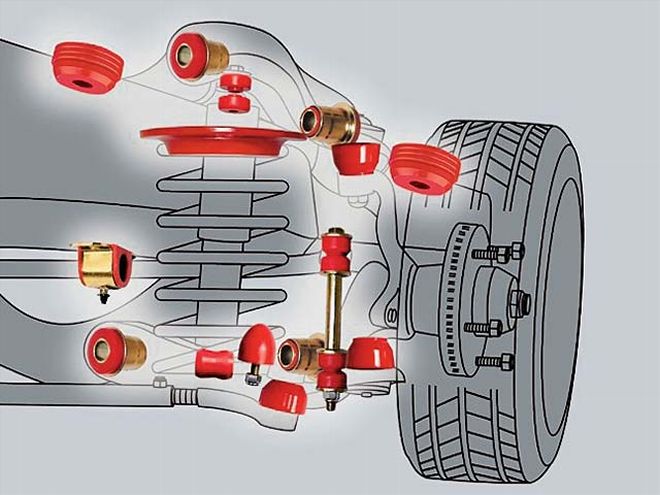

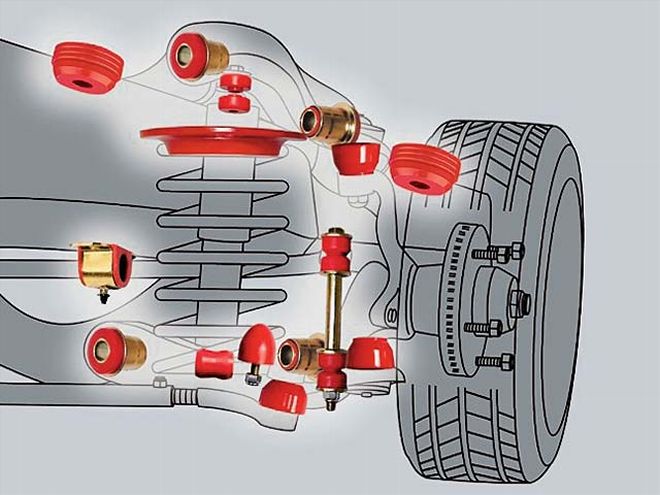

| We got this image from Energy because it displays perfectly where everything goes on a typical coil spring truck.

We went to the company's facility to have the technicians install most of the stuff and show us how to keep them from squeaking. Energy's Master Sets offer complete coverage of the vehicle's chassis from front to back all the way down to the cab mounts. Again, we are just focusing on the suspension, so we will install the cab, motor, and tranny mounts at a later date.

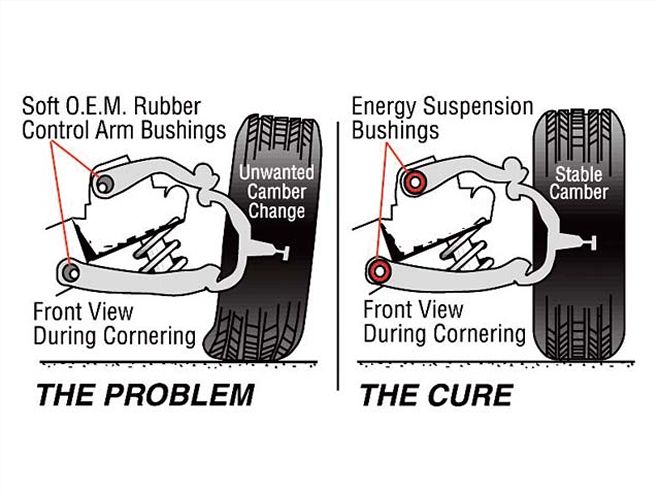

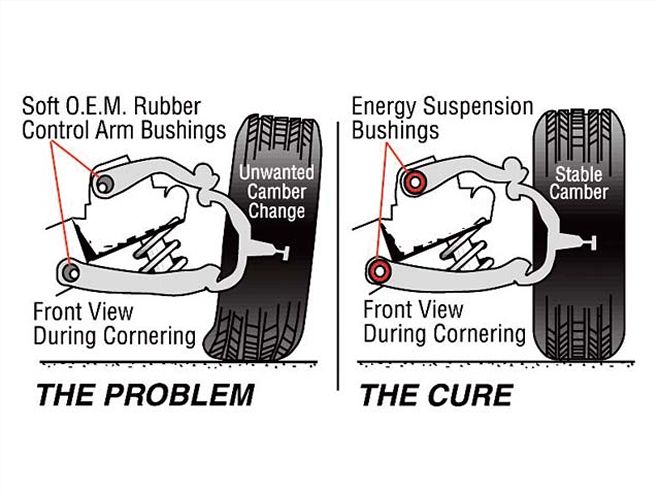

| This illustration shows very clearly the benefit of the firmer polyurethane bushings over factory rubber.

There is a big urban legend going around that polyurethane bushings squeak. This is not entirely true. Any bushing will squeak, if you install it wrong or don't lube it enough. This is why we went straight to the source to see how they do it, and we found out that your best weapon against the squeak beside a proper installation is the company's Formula 5 Prelube. This stuff is a waterproof, non-melting grease containing Teflon. It forms a tough, durable, chemical-resistant film of lubricant to prevent metal-to-metal contact, even under severe shock loads. Only a small amount is required to properly lubricate bushings and metal components, as well as prevent corrosion, but we used a bunch of it and just wiped off the excess. Follow along as we get rid of the rubber and get one step closer to carving up the road.

| Made in America has never been truer. Besides the plating of the sleeves, everything is constructed in-house at Energy's facility in San Clemente, California.

Tools Used:·Sockets or Wrenches

·1-1/16

·15/16

·13/16

·11/16

·24mm

·21mm

·Side Cutters

·Channel Lock Pliers

·Hammer

·Assortment of Prybars

·Assortment of Screwdrivers

·Chisel

·Air Hammer

·Bench Press

·Vise

·Impact Gun

| Here is the Master Set from Energy Suspension, which as you can see is very complete, hence the name Master Set. It includes upper and lower control arm bushings, leaf spring bushings, sway bar bushings, endlinks, motor mounts, transmission mount, ball joint boots, and tie rod boots.

Last month, we launched a build to turn a stock '94 Chevrolet Truck into a daily driveable G-Machine. To bring you up to speed, we installed a DJM lowering kit that we got from Stylin' Concepts, which included 2-inch drop springs for the front and a 4-inch shackle/hanger kit for the rear. Those components lowered the truck's center of gravity and will make good use of the fat sticky rubber and strong wheels we bolted up. The wheels we used are Ultra Wheel's new Hot Schott in an 18x9-inch size with a 10mm offset. They are a Counter Pressure Cast one-piece construction that will provide plenty of rigidity, and the chrome finish will be easy to maintain. Surrounding the Schotts is a set of Nitto's 295/45ZR18 NT-555s, which will give us the fat contact patch we want for traction. And since all four tires are the same size, we can rotate them to prolong their life.

| Here is the Master Set from Energy Suspension, which as you can see is very complete, hence the name Master Set. It includes upper and lower control arm bushings, leaf spring bushings, sway bar bushings, endlinks, motor mounts, transmission mount, ball joint boots, and tie rod boots.

Last month, we launched a build to turn a stock '94 Chevrolet Truck into a daily driveable G-Machine. To bring you up to speed, we installed a DJM lowering kit that we got from Stylin' Concepts, which included 2-inch drop springs for the front and a 4-inch shackle/hanger kit for the rear. Those components lowered the truck's center of gravity and will make good use of the fat sticky rubber and strong wheels we bolted up. The wheels we used are Ultra Wheel's new Hot Schott in an 18x9-inch size with a 10mm offset. They are a Counter Pressure Cast one-piece construction that will provide plenty of rigidity, and the chrome finish will be easy to maintain. Surrounding the Schotts is a set of Nitto's 295/45ZR18 NT-555s, which will give us the fat contact patch we want for traction. And since all four tires are the same size, we can rotate them to prolong their life. | We will install the motor mounts at a later date, but we still wanted to let you see them.

This month, we will move a little deeper and replace all the factory rubber bushings with a performance-minded set of polyurethane bushings from Energy Suspension. Unless you have been trapped in your garage for way too long, then you already know what the benefits are. But, just in case, we will go over them. There are two main purposes of the suspension bushings: One is to allow the pivot points to move and the second is to isolate and damp vibrations transferred from the road. The factory uses rubber because it does a great job at damping. And yes, it allows the pivots to move, but usually it's relatively soft and will deflect under heavy loads. When you turn a corner, the bushing is subjected to increased load, and if the bushing deflects, then a lot of things can change like caster, camber, and toe settings. Over time, this increased load can compress most rubber permanently, and such was the case of our '94. When we got the arms out, we could see the bolt hole was not centered in the bushing. Energy's special formula Hyper-Flex performance polyurethane components feature a higher durometer (firmness) material that will last longer and provide a solid base for our suspension.

| We will install the motor mounts at a later date, but we still wanted to let you see them.

This month, we will move a little deeper and replace all the factory rubber bushings with a performance-minded set of polyurethane bushings from Energy Suspension. Unless you have been trapped in your garage for way too long, then you already know what the benefits are. But, just in case, we will go over them. There are two main purposes of the suspension bushings: One is to allow the pivot points to move and the second is to isolate and damp vibrations transferred from the road. The factory uses rubber because it does a great job at damping. And yes, it allows the pivots to move, but usually it's relatively soft and will deflect under heavy loads. When you turn a corner, the bushing is subjected to increased load, and if the bushing deflects, then a lot of things can change like caster, camber, and toe settings. Over time, this increased load can compress most rubber permanently, and such was the case of our '94. When we got the arms out, we could see the bolt hole was not centered in the bushing. Energy's special formula Hyper-Flex performance polyurethane components feature a higher durometer (firmness) material that will last longer and provide a solid base for our suspension.

| We got this image from Energy because it displays perfectly where everything goes on a typical coil spring truck.

We went to the company's facility to have the technicians install most of the stuff and show us how to keep them from squeaking. Energy's Master Sets offer complete coverage of the vehicle's chassis from front to back all the way down to the cab mounts. Again, we are just focusing on the suspension, so we will install the cab, motor, and tranny mounts at a later date.

| We got this image from Energy because it displays perfectly where everything goes on a typical coil spring truck.

We went to the company's facility to have the technicians install most of the stuff and show us how to keep them from squeaking. Energy's Master Sets offer complete coverage of the vehicle's chassis from front to back all the way down to the cab mounts. Again, we are just focusing on the suspension, so we will install the cab, motor, and tranny mounts at a later date.  | This illustration shows very clearly the benefit of the firmer polyurethane bushings over factory rubber.

There is a big urban legend going around that polyurethane bushings squeak. This is not entirely true. Any bushing will squeak, if you install it wrong or don't lube it enough. This is why we went straight to the source to see how they do it, and we found out that your best weapon against the squeak beside a proper installation is the company's Formula 5 Prelube. This stuff is a waterproof, non-melting grease containing Teflon. It forms a tough, durable, chemical-resistant film of lubricant to prevent metal-to-metal contact, even under severe shock loads. Only a small amount is required to properly lubricate bushings and metal components, as well as prevent corrosion, but we used a bunch of it and just wiped off the excess. Follow along as we get rid of the rubber and get one step closer to carving up the road.

| This illustration shows very clearly the benefit of the firmer polyurethane bushings over factory rubber.

There is a big urban legend going around that polyurethane bushings squeak. This is not entirely true. Any bushing will squeak, if you install it wrong or don't lube it enough. This is why we went straight to the source to see how they do it, and we found out that your best weapon against the squeak beside a proper installation is the company's Formula 5 Prelube. This stuff is a waterproof, non-melting grease containing Teflon. It forms a tough, durable, chemical-resistant film of lubricant to prevent metal-to-metal contact, even under severe shock loads. Only a small amount is required to properly lubricate bushings and metal components, as well as prevent corrosion, but we used a bunch of it and just wiped off the excess. Follow along as we get rid of the rubber and get one step closer to carving up the road.

| Made in America has never been truer. Besides the plating of the sleeves, everything is constructed in-house at Energy's facility in San Clemente, California.

Tools Used:·Sockets or Wrenches

| Made in America has never been truer. Besides the plating of the sleeves, everything is constructed in-house at Energy's facility in San Clemente, California.

Tools Used:·Sockets or Wrenches