In the November/December 2004 issue, we presented an inside look at the buildup of a 1989 Silverado hot rod, in which a 4700-pound half-ton 4x4 was given the brawny capability of GM's Duramax 6600 diesel engine and Allison automatic. The plan was to create a unique, fun-to-drive, performance-oriented full-size four-wheel-drive sport truck with a modern diesel powertrain.

When running stock programming for 300 horsepower and 520 pound-feet of torque, quarter-mile performance already was excellent at 15.3 seconds and 98.5 mph. The speed at which power can be ramped up with these modern diesels was difficult to imagine just a few years ago. In addition, there are now a variety of aftermarket power products available to take performance to the next level and beyond.

| 1989 Chevrolet Silverado K1500 engine View

Most of the aftermarket power modules and programmers available for the Duramax stay within the 90-150-horsepower level that tests the torque limits of the Allison, while not producing excessive (and obnoxious) levels of exhaust smoke. In this truck, a 150-horsepower Edge/Attitude module will push performance to a 13.7-second ET and 107 mph in the quarter mile. The difference between running in 2WD and 4WD amounts to about 0.2 second at this power level, with lower ET's coming in 4WD, but with slightly higher trap speeds (109 mph) in 2WD. This is with an otherwise untouched engine and transmission.

| 1989 Chevrolet Silverado K1500 Flareside 4x4 Pickup interior Driver

Moving beyond the 150-horsepower level reduces the field of available products, leaving us with a competition power module or a custom programmer. It takes an ability to produce a lot of black exhaust smoke to make big power. These products can deliver fuel equivalent of 200-220 additional horsepower, which is too much for street use and way too smoky to be practical without further vehicle modifications. However, when used with a competition module or programmer, the right amount of nitrous will add 270-320 additional rear-wheel horsepower above stock--with a lot less smoke. Depending on the combination of components and how an individual engine responds to tuning, the Duramax could be producing more than 600 horsepower and 900 to 1000 pound-feet of torque.

During its first race season, our goal was to get into the 12s, which was accomplished with a best run of 12.8 seconds at 111 mph. Now that the season's over, we'll work on a few chassis refinements and plan to significantly improve performance by next season. At more than 1000 pounds lighter than a stripped-down heavy-duty 2WD 3/4-ton GM diesel pickup, our street-legal and air-conditioned 4x4 hot rod definitely has an advantage.

While a highly modified big-block gas engine might produce 12-second performance in a similar truck, it also loses much of its streetability and gets abysmal fuel economy. Our Duramax hot rod will produce nearly 25 mpg cruising at 75 to 80 mph on the Interstate, with road manners that return to normal by switching off the extra power.

We drove the truck through the summer with the original 3.42:1 differential gearing, but considered installing 3.73s to match those used by GM's new diesel pickups. However, after discovering the ease at which it cruised at speed on the highway (while getting excellent fuel economy) and how it performed at the track, we decided to keep the 3.42:1 gearing. Someone with the willpower to drive at a more sedate speed could probably get even better fuel economy by another two or three mpg.

The Allison is arguably the toughest automatic transmission offered in a light-duty truck to date, but there's a limit to how much torque it can handle. Designed to live behind a factory Duramax 6600 (rated at 615 pound-feet of torque as of January 2005), the Allison torque limit will be exceeded with some of the higher-rated aftermarket power products in a conventional 3/4- or one-ton truck. However, Allison engineers and diesel race enthusiasts have suggested that this lightweight hot rod could likely "squirt" out from under the factory Allison torque limit. We've yet to slip the Allison during a clean launch, but we're watching a number of companies that offer performance transmission upgrades, should the need arise.

This has been a fun project that'll see continued development and may even appear at a couple of the larger diesel-pickup events during the upcoming season. Keep your eyes open at any number of diesel drag races around the country. You may see us there.

| Spring wrap and wheelhop hurt performance and create a potential for drivetrain damage. Kennedy Diesel equipped our truck with a set of NHRA-qualified CalTracs traction bars designed to help keep the rubber firmly planted and improve the launch. These help prevent spring wrap and maintain the pinion angle during a hard launch.

| Nitrous oxide is required to push quarter-mile performance into the 12s or better. The amount of fuel required for 600-plus horsepower exceeds the ability of 30 psi turbo-boost pressure to burn efficiently. The added oxygen provided by nitrous makes up the difference. U.S. Diesel Parts set us up with a two-stage adjustable NOx kit that can be fine-tuned to match current and future fueling requirements.

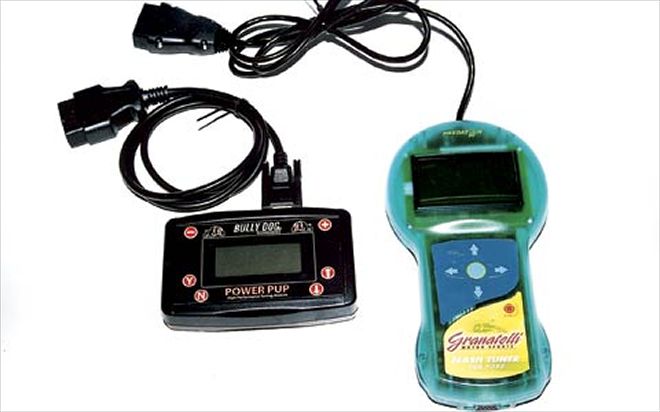

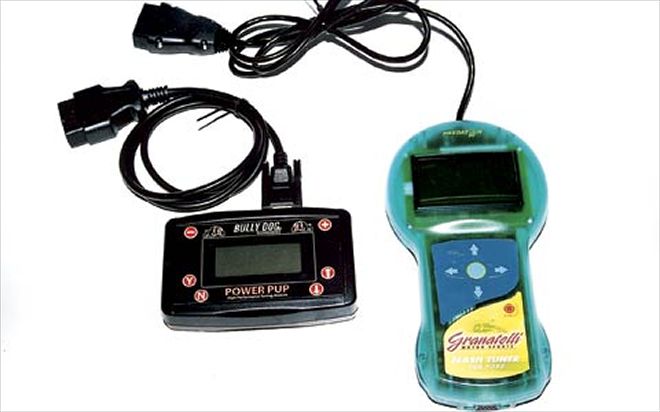

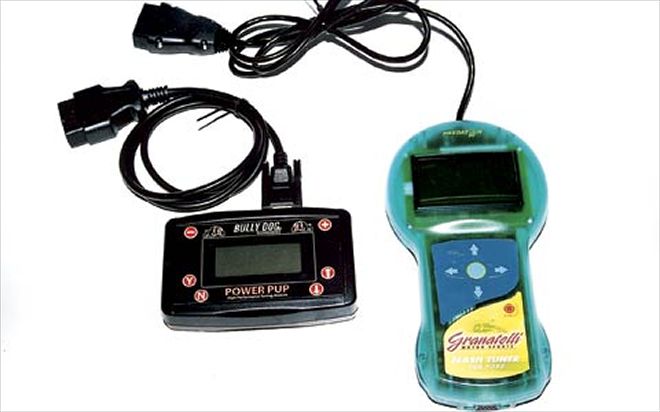

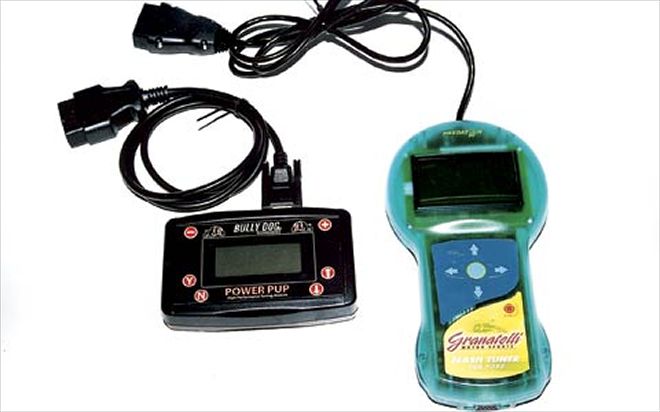

| Power modules and programmers allow for an easy power gain and competition versions can double rear-wheel power.

| The Banks Big Head turbo wastegate actuator helps raise boost pressure from a stock level of about 21 psi to approximately 30 by using a larger diaphragm, plus more spring pressure and an adjustable linkage. More air, more boost, and more fuel equals more power.

| The original half-ton rear axle had to go. The strongest rear axle available for a GM six-lug application is the 14-bolt semi-floater with a 9.5-inch-diameter ring gear. Randy's Ring & Pinion, in Everett, Washington, was given the task of rebuilding our replacement axle to precision specs using an Eaton Positraction differential, new ring and pinion, and new bearings and seals.

| 1989 Chevrolet Silverado K1500 engine View

Most of the aftermarket power modules and programmers available for the Duramax stay within the 90-150-horsepower level that tests the torque limits of the Allison, while not producing excessive (and obnoxious) levels of exhaust smoke. In this truck, a 150-horsepower Edge/Attitude module will push performance to a 13.7-second ET and 107 mph in the quarter mile. The difference between running in 2WD and 4WD amounts to about 0.2 second at this power level, with lower ET's coming in 4WD, but with slightly higher trap speeds (109 mph) in 2WD. This is with an otherwise untouched engine and transmission.

| 1989 Chevrolet Silverado K1500 engine View

Most of the aftermarket power modules and programmers available for the Duramax stay within the 90-150-horsepower level that tests the torque limits of the Allison, while not producing excessive (and obnoxious) levels of exhaust smoke. In this truck, a 150-horsepower Edge/Attitude module will push performance to a 13.7-second ET and 107 mph in the quarter mile. The difference between running in 2WD and 4WD amounts to about 0.2 second at this power level, with lower ET's coming in 4WD, but with slightly higher trap speeds (109 mph) in 2WD. This is with an otherwise untouched engine and transmission.

| 1989 Chevrolet Silverado K1500 Flareside 4x4 Pickup interior Driver

Moving beyond the 150-horsepower level reduces the field of available products, leaving us with a competition power module or a custom programmer. It takes an ability to produce a lot of black exhaust smoke to make big power. These products can deliver fuel equivalent of 200-220 additional horsepower, which is too much for street use and way too smoky to be practical without further vehicle modifications. However, when used with a competition module or programmer, the right amount of nitrous will add 270-320 additional rear-wheel horsepower above stock--with a lot less smoke. Depending on the combination of components and how an individual engine responds to tuning, the Duramax could be producing more than 600 horsepower and 900 to 1000 pound-feet of torque.

During its first race season, our goal was to get into the 12s, which was accomplished with a best run of 12.8 seconds at 111 mph. Now that the season's over, we'll work on a few chassis refinements and plan to significantly improve performance by next season. At more than 1000 pounds lighter than a stripped-down heavy-duty 2WD 3/4-ton GM diesel pickup, our street-legal and air-conditioned 4x4 hot rod definitely has an advantage.

While a highly modified big-block gas engine might produce 12-second performance in a similar truck, it also loses much of its streetability and gets abysmal fuel economy. Our Duramax hot rod will produce nearly 25 mpg cruising at 75 to 80 mph on the Interstate, with road manners that return to normal by switching off the extra power.

We drove the truck through the summer with the original 3.42:1 differential gearing, but considered installing 3.73s to match those used by GM's new diesel pickups. However, after discovering the ease at which it cruised at speed on the highway (while getting excellent fuel economy) and how it performed at the track, we decided to keep the 3.42:1 gearing. Someone with the willpower to drive at a more sedate speed could probably get even better fuel economy by another two or three mpg.

The Allison is arguably the toughest automatic transmission offered in a light-duty truck to date, but there's a limit to how much torque it can handle. Designed to live behind a factory Duramax 6600 (rated at 615 pound-feet of torque as of January 2005), the Allison torque limit will be exceeded with some of the higher-rated aftermarket power products in a conventional 3/4- or one-ton truck. However, Allison engineers and diesel race enthusiasts have suggested that this lightweight hot rod could likely "squirt" out from under the factory Allison torque limit. We've yet to slip the Allison during a clean launch, but we're watching a number of companies that offer performance transmission upgrades, should the need arise.

This has been a fun project that'll see continued development and may even appear at a couple of the larger diesel-pickup events during the upcoming season. Keep your eyes open at any number of diesel drag races around the country. You may see us there.

| 1989 Chevrolet Silverado K1500 Flareside 4x4 Pickup interior Driver

Moving beyond the 150-horsepower level reduces the field of available products, leaving us with a competition power module or a custom programmer. It takes an ability to produce a lot of black exhaust smoke to make big power. These products can deliver fuel equivalent of 200-220 additional horsepower, which is too much for street use and way too smoky to be practical without further vehicle modifications. However, when used with a competition module or programmer, the right amount of nitrous will add 270-320 additional rear-wheel horsepower above stock--with a lot less smoke. Depending on the combination of components and how an individual engine responds to tuning, the Duramax could be producing more than 600 horsepower and 900 to 1000 pound-feet of torque.

During its first race season, our goal was to get into the 12s, which was accomplished with a best run of 12.8 seconds at 111 mph. Now that the season's over, we'll work on a few chassis refinements and plan to significantly improve performance by next season. At more than 1000 pounds lighter than a stripped-down heavy-duty 2WD 3/4-ton GM diesel pickup, our street-legal and air-conditioned 4x4 hot rod definitely has an advantage.

While a highly modified big-block gas engine might produce 12-second performance in a similar truck, it also loses much of its streetability and gets abysmal fuel economy. Our Duramax hot rod will produce nearly 25 mpg cruising at 75 to 80 mph on the Interstate, with road manners that return to normal by switching off the extra power.

We drove the truck through the summer with the original 3.42:1 differential gearing, but considered installing 3.73s to match those used by GM's new diesel pickups. However, after discovering the ease at which it cruised at speed on the highway (while getting excellent fuel economy) and how it performed at the track, we decided to keep the 3.42:1 gearing. Someone with the willpower to drive at a more sedate speed could probably get even better fuel economy by another two or three mpg.

The Allison is arguably the toughest automatic transmission offered in a light-duty truck to date, but there's a limit to how much torque it can handle. Designed to live behind a factory Duramax 6600 (rated at 615 pound-feet of torque as of January 2005), the Allison torque limit will be exceeded with some of the higher-rated aftermarket power products in a conventional 3/4- or one-ton truck. However, Allison engineers and diesel race enthusiasts have suggested that this lightweight hot rod could likely "squirt" out from under the factory Allison torque limit. We've yet to slip the Allison during a clean launch, but we're watching a number of companies that offer performance transmission upgrades, should the need arise.

This has been a fun project that'll see continued development and may even appear at a couple of the larger diesel-pickup events during the upcoming season. Keep your eyes open at any number of diesel drag races around the country. You may see us there.

| Spring wrap and wheelhop hurt performance and create a potential for drivetrain damage. Kennedy Diesel equipped our truck with a set of NHRA-qualified CalTracs traction bars designed to help keep the rubber firmly planted and improve the launch. These help prevent spring wrap and maintain the pinion angle during a hard launch.

| Spring wrap and wheelhop hurt performance and create a potential for drivetrain damage. Kennedy Diesel equipped our truck with a set of NHRA-qualified CalTracs traction bars designed to help keep the rubber firmly planted and improve the launch. These help prevent spring wrap and maintain the pinion angle during a hard launch.

| Nitrous oxide is required to push quarter-mile performance into the 12s or better. The amount of fuel required for 600-plus horsepower exceeds the ability of 30 psi turbo-boost pressure to burn efficiently. The added oxygen provided by nitrous makes up the difference. U.S. Diesel Parts set us up with a two-stage adjustable NOx kit that can be fine-tuned to match current and future fueling requirements.

| Nitrous oxide is required to push quarter-mile performance into the 12s or better. The amount of fuel required for 600-plus horsepower exceeds the ability of 30 psi turbo-boost pressure to burn efficiently. The added oxygen provided by nitrous makes up the difference. U.S. Diesel Parts set us up with a two-stage adjustable NOx kit that can be fine-tuned to match current and future fueling requirements.

| Power modules and programmers allow for an easy power gain and competition versions can double rear-wheel power.

| Power modules and programmers allow for an easy power gain and competition versions can double rear-wheel power.

| The Banks Big Head turbo wastegate actuator helps raise boost pressure from a stock level of about 21 psi to approximately 30 by using a larger diaphragm, plus more spring pressure and an adjustable linkage. More air, more boost, and more fuel equals more power.

| The Banks Big Head turbo wastegate actuator helps raise boost pressure from a stock level of about 21 psi to approximately 30 by using a larger diaphragm, plus more spring pressure and an adjustable linkage. More air, more boost, and more fuel equals more power.

| The original half-ton rear axle had to go. The strongest rear axle available for a GM six-lug application is the 14-bolt semi-floater with a 9.5-inch-diameter ring gear. Randy's Ring & Pinion, in Everett, Washington, was given the task of rebuilding our replacement axle to precision specs using an Eaton Positraction differential, new ring and pinion, and new bearings and seals.

| The original half-ton rear axle had to go. The strongest rear axle available for a GM six-lug application is the 14-bolt semi-floater with a 9.5-inch-diameter ring gear. Randy's Ring & Pinion, in Everett, Washington, was given the task of rebuilding our replacement axle to precision specs using an Eaton Positraction differential, new ring and pinion, and new bearings and seals.