We’re pretty sure there are statistics somewhere that will support our incredibly wild guess that more diesel pickups in service today are equipped with automatic transmissions than manual gearboxes. While our confidence in this claim is spread across the Big Three major U.S. brands, we do acknowledge the statement could be questionable for Dodges and Rams, of which quite a few feature stick-shifted transmissions.

Why is this so? We’ll cite simple “driver convenience” as a reason, because despite manual transmissions’ lower cost, they require much more effort to operate (constant clutch operation and gear selection, especially in stop-and-go driving conditions) than their automatic counterparts.

Of course, the versatility and efficiency computer-controlled automatics have over manual transmissions undoubtedly also has an influence on a manufacturer’s decision to offer autos as standard equipment in new rigs. However, because of the severe-duty uses that transmissions, both new and old, are often subjected to (towing, carrying very heavy payloads) and the extreme heat that is created inside automatic units, their durability oftentimes leaves a lot to be desired.

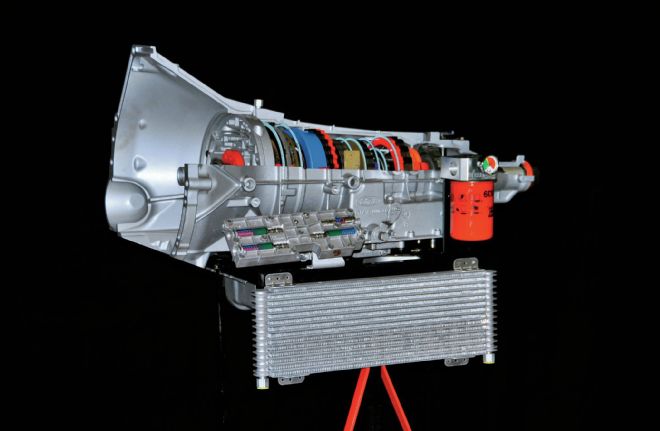

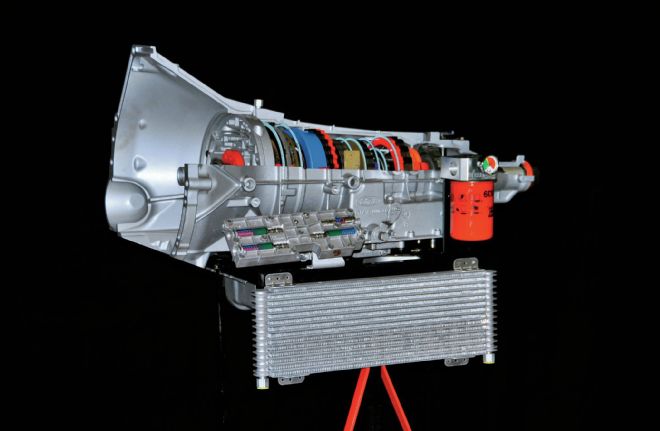

| The colorful insides of this cutaway detail the high-quality parts that go into every DieselSite transmission build. Additional friction plates (made with the most modern materials available) are in abundance, better snap rings are used, and all the areas that are prone to internal leaking are sealed.

In this report, we focus our attention on Ford’s first completely electronic, light-truck automatic, the E4OD: a spin off of the hydraulically managed, three-speed C6. Initially selected for the company’s SVT F-150 Lightnings, E4OD four-speeds were used in the pickups and vans from ’89 to ’99.

Durability issues plagued E4ODs that were installed behind 6.9L and 7.3L IDI diesels (from ’89 to ’93), and then mated to direct-injected 7.3L Power Stroke engines starting in 1994. With torque for these diesel engines being considerably higher than that of their gasoline-powered counterparts (the 302, 351W, and 460) at that time—and due to the aforementioned stresses that were imposed on the transmissions—rebuilds were fairly common for units that were still well in front of having 100,000 miles.

While E4ODs received updates from the factory throughout their run (the final improvement was made in 1998), Ford completely replaced the transmissions in 7.3L-powered trucks the following year with stronger units that it called 4R100. The new, heavy-duty, automatic four-speeds were said to support as much as 1,000 lb-ft of torque, which made them perfect workhorse transmissions for stock rigs.

| DieselSite starts by completely tearing down transmission cores it has procured independently or received from customers (to avoid a core charge). All parts are cleaned and inspected, then either saved for reuse or tossed into the recycle bin—especially OEM hardware, since it is replaced with better parts. In this photo, a valvebody is being removed.

The evil irony with this final upgrade is that the stronger 4R100s were built using a bigger cast-aluminum case (than the E4OD), which was designed for fitment beneath the new-body-style ’99 Super Duty pickups. This essentially made swapping the stronger units into old-body-style ’94 to ’98s impossible, sticking OBS owners with rebuilt E4ODs as their only solution when a beefy transmission is necessary.

We like hearing about new innovations for OBS diesel Fords, especially when such developments are designed to help bring the older vehicles into a newer age. dieselsite.com’s “Legendary” E4OD heavy-duty transmission ($3,399) and billet, multi-disc torque converter ($600) are upgraded pieces that company owner Bob Riley has designed to do exactly that: put the strength and reliability of an 4R100 in an E4OD’s package.

With our ’95 F-350’s E4OD showing signs of possibly having an internal issue (high oil temperatures, soft shifts, and some slipping) and with a major failure potentially on the horizon, we consulted with Bob and elected to replace the 138,000-mile unit with DieselSite’s new transmission.

To take this report beyond just presenting the rudiments of simple transmission installation and to get a clearer understanding of how DieselSite’s upgrades improve E4ODs, we followed along as Bob assembled and dyno tested the Legendary automatic.

Installation and Testing

Temperature

Our F-350’s new transmission was tested in both freeway and city-street driving conditions, with and without an enclosed trailer loaded with a 3,400-pound car, golf cart, tools, and such attached to the truck. In all scenarios (and with an ambient temperature of approximately 65 degrees), shifts are smooth and very crisp (not head-snapping hard), and the transmission temperature never surpassed 150 degrees. As a rule of thumb, the trans temp shouldn’t top 200 degrees. The truck’s original transmission experienced more than 250 degrees during one towing experience on the infamous “Grapevine” grade, near Bakersfield, California (we did stop for about an hour when this happened to cool the transmission and ensure we made it home). When you figure that a transmission’s life is cut by a factor of two for every 20 degrees over 200 degrees, we were definitely operating on borrowed time after that incident—and making the move to the DieselSite transmission really was a good idea.

| The colorful insides of this cutaway detail the high-quality parts that go into every DieselSite transmission build. Additional friction plates (made with the most modern materials available) are in abundance, better snap rings are used, and all the areas that are prone to internal leaking are sealed.

In this report, we focus our attention on Ford’s first completely electronic, light-truck automatic, the E4OD: a spin off of the hydraulically managed, three-speed C6. Initially selected for the company’s SVT F-150 Lightnings, E4OD four-speeds were used in the pickups and vans from ’89 to ’99.

Durability issues plagued E4ODs that were installed behind 6.9L and 7.3L IDI diesels (from ’89 to ’93), and then mated to direct-injected 7.3L Power Stroke engines starting in 1994. With torque for these diesel engines being considerably higher than that of their gasoline-powered counterparts (the 302, 351W, and 460) at that time—and due to the aforementioned stresses that were imposed on the transmissions—rebuilds were fairly common for units that were still well in front of having 100,000 miles.

While E4ODs received updates from the factory throughout their run (the final improvement was made in 1998), Ford completely replaced the transmissions in 7.3L-powered trucks the following year with stronger units that it called 4R100. The new, heavy-duty, automatic four-speeds were said to support as much as 1,000 lb-ft of torque, which made them perfect workhorse transmissions for stock rigs.

| The colorful insides of this cutaway detail the high-quality parts that go into every DieselSite transmission build. Additional friction plates (made with the most modern materials available) are in abundance, better snap rings are used, and all the areas that are prone to internal leaking are sealed.

In this report, we focus our attention on Ford’s first completely electronic, light-truck automatic, the E4OD: a spin off of the hydraulically managed, three-speed C6. Initially selected for the company’s SVT F-150 Lightnings, E4OD four-speeds were used in the pickups and vans from ’89 to ’99.

Durability issues plagued E4ODs that were installed behind 6.9L and 7.3L IDI diesels (from ’89 to ’93), and then mated to direct-injected 7.3L Power Stroke engines starting in 1994. With torque for these diesel engines being considerably higher than that of their gasoline-powered counterparts (the 302, 351W, and 460) at that time—and due to the aforementioned stresses that were imposed on the transmissions—rebuilds were fairly common for units that were still well in front of having 100,000 miles.

While E4ODs received updates from the factory throughout their run (the final improvement was made in 1998), Ford completely replaced the transmissions in 7.3L-powered trucks the following year with stronger units that it called 4R100. The new, heavy-duty, automatic four-speeds were said to support as much as 1,000 lb-ft of torque, which made them perfect workhorse transmissions for stock rigs.

| DieselSite starts by completely tearing down transmission cores it has procured independently or received from customers (to avoid a core charge). All parts are cleaned and inspected, then either saved for reuse or tossed into the recycle bin—especially OEM hardware, since it is replaced with better parts. In this photo, a valvebody is being removed.

The evil irony with this final upgrade is that the stronger 4R100s were built using a bigger cast-aluminum case (than the E4OD), which was designed for fitment beneath the new-body-style ’99 Super Duty pickups. This essentially made swapping the stronger units into old-body-style ’94 to ’98s impossible, sticking OBS owners with rebuilt E4ODs as their only solution when a beefy transmission is necessary.

We like hearing about new innovations for OBS diesel Fords, especially when such developments are designed to help bring the older vehicles into a newer age. dieselsite.com’s “Legendary” E4OD heavy-duty transmission ($3,399) and billet, multi-disc torque converter ($600) are upgraded pieces that company owner Bob Riley has designed to do exactly that: put the strength and reliability of an 4R100 in an E4OD’s package.

With our ’95 F-350’s E4OD showing signs of possibly having an internal issue (high oil temperatures, soft shifts, and some slipping) and with a major failure potentially on the horizon, we consulted with Bob and elected to replace the 138,000-mile unit with DieselSite’s new transmission.

To take this report beyond just presenting the rudiments of simple transmission installation and to get a clearer understanding of how DieselSite’s upgrades improve E4ODs, we followed along as Bob assembled and dyno tested the Legendary automatic.

| DieselSite starts by completely tearing down transmission cores it has procured independently or received from customers (to avoid a core charge). All parts are cleaned and inspected, then either saved for reuse or tossed into the recycle bin—especially OEM hardware, since it is replaced with better parts. In this photo, a valvebody is being removed.

The evil irony with this final upgrade is that the stronger 4R100s were built using a bigger cast-aluminum case (than the E4OD), which was designed for fitment beneath the new-body-style ’99 Super Duty pickups. This essentially made swapping the stronger units into old-body-style ’94 to ’98s impossible, sticking OBS owners with rebuilt E4ODs as their only solution when a beefy transmission is necessary.

We like hearing about new innovations for OBS diesel Fords, especially when such developments are designed to help bring the older vehicles into a newer age. dieselsite.com’s “Legendary” E4OD heavy-duty transmission ($3,399) and billet, multi-disc torque converter ($600) are upgraded pieces that company owner Bob Riley has designed to do exactly that: put the strength and reliability of an 4R100 in an E4OD’s package.

With our ’95 F-350’s E4OD showing signs of possibly having an internal issue (high oil temperatures, soft shifts, and some slipping) and with a major failure potentially on the horizon, we consulted with Bob and elected to replace the 138,000-mile unit with DieselSite’s new transmission.

To take this report beyond just presenting the rudiments of simple transmission installation and to get a clearer understanding of how DieselSite’s upgrades improve E4ODs, we followed along as Bob assembled and dyno tested the Legendary automatic.