According to Tom Lee, owner of Lee’s Power Steering in Sun Valley, California, one of the few systems that has not changed since the ’60s is the steering pump and steering gearbox. Tom should know—he established Lee Manufacturing in 1965 and has earned the reputation as an undisputed authority on performance steering. From military applications and desert racing sprint cars to stock cars and Formula One, many winners have crossed the finish line with Tom’s steering systems.

Arguably, steering is the most important part of your vehicle. Think about it. No matter what else works, your steering is the key. No matter how fast or slow you might be going, or what the situation is, if you can’t steer, you are in big trouble. Really big trouble!

So you’re driving an eight-lug heavy-duty truck. It just doesn’t get any tougher, does it? Over the last 30 years or so, Ford, Dodge, and GM/Chevy have listened to their customers. Cool stuff that owners used to add now come stock or at least as an option: comfortable bucket seats (when’s the last time you sat in a bench seat?), power everything, steps, bigger engines, and more. It’s a long list of great improvements, but the result has been an accent on the “heavy” of your heavy-duty truck.

| power Steering Upgrade 1999 Ford F550 Powersteering Rebuild powersteering Surgery

When we started to hear a couple of horror stories about pre-’04 Ford sector shafts cracking or breaking, we decided to take a closer look. As it turns out, it’s not just a Ford problem. The crack is often instigated by overtightening the nut, which forces the Pitman arm over the end of the splined end of the shaft. If you have a stock truck and drive it normally, there’s less chance of a problem other than sloppy control. On the other hand, if you’ve lifted your truck, added some 40-inch rubber, and drive aggressively on roads that might keep Detroit engineers awake, you can’t really blame the OEM if something breaks.

| 01. Judging by the rust marks on the left, this sector shaft was cracked long before it broke off.

There have been cases of broken sector shafts, in some instances with catastrophic results. As we begin final preparations for a three-year expedition following the infamous Silk Road across Europe and Asia, every system on our ’99 F-550 must be in absolute top condition. Our 14,000-pound loaded GVW and the 40.7-inch Michelin XZL tires put additional stress on the entire steering system.

First of all, you might not even know what a sector shaft is. It’s the round thingy sticking out the bottom of your steering gearbox. The Pitman arm attaches to it with a big bolt, and that’s connected to the drag link, which ultimately connects to your hand on the steering wheel. In other words, it’s the final mechanical link between you and the direction your truck is moving—even if everything else is dead.

| 02. When a sector shaft breaks, you no longer have any steering. Zero!

Steering is funny. It’s sort of like your eyesight. Over the years (and miles), it very slowly deteriorates until one day you wake up and you know you need glasses. So one day you’re driving down the highway and you notice there’s a third of a turn in the steering wheel before the vehicle changes direction. That can be exciting on the freeway at 70 mph, or on a windy mountain road. Worse still, you’re following your favorite backroad and you hit a bad rut a little fast, and when you turn the wheel, nothing happens.

| 15. Our modified fluid reservoir was painted and ready to install on the pump.

Tom was very familiar with the weaknesses of a Ford OEM pump and gearbox. We previously had Vanco Power Brake Supply in South Gate, California, do some porting on our hydroboost to allow additional pressure to flow uninterrupted. Now the pump and gearbox could be rebuilt and modified to Tom’s specifications. He appreciated that on a narrow mountain rock-strewn road in Tajikistan, we needed absolute reliability as well as performance.

With our top alternator set aside and the serpentine belt removed, the technicians at Lee’s Power Steering unbolted the huge cast bracket that holds both the alternator and the power steering pump. The gearbox was extracted from the bottom. We would be able to use our original gearbox housing, since it already had fittings welded on for a ram assist, leftover from a previous system that proved unreliable.

| 16. Installing the flow control fitting was the final step before bench testing.

While the gearhousing was cleaned, sandblasted, honed out, and marked for future reference, Ignacio Vertti started on our new pump. It was quite amazing just how many parts make up a steering pump. For its additional performance and reliability, we used a Saginaw body. The Saginaw pump uses a blade-vane design. Our Ford pump used a slipper-vane design, which Tom said produces more heat.

Ignacio machined out the control fitting for a flow rate of 3½ gallons per minute (gpm). Stock was 2 gpm. A higher flow rate creates more heat, but we would still be safe. Lee’s race pumps typically flow 8 gpm, but these require a remote reservoir to keep the heat down, something we are considering at a later date. The pressure piston used on our pump was calibrated for 1,600 pounds.

All new parts were used, including the shaft, flow control, piston and spring cap, and all seals. Finding the best possible can or fluid reservoir to replace the OEM plastic one was interesting. There are at least 50 different shapes and sizes, due to the number of different vehicles GM used the Saginaw pump on, from Cadillacs, Buicks, and Pontiacs, to Chevy cars and trucks—each with different engines, bolt patterns, and space restrictions. With a trained eye, Ignacio took one off the shelf with the correct “clock” and a design to fit the tight space next to our turbo intake pipe. Tom welded on a fitting for the hydroboost return.

| 17. On the test machine, Ignacio Vertti ran our pump up to 1,600 pounds and checked its flow rate of 3.5 gpm. A normal truck seldom sees more than 1,400 pounds.

When the pump and new can were assembled, they were attached to a test bench to check for balance, proper flow rate, and leakage. The test bench looks like some kind of heart/lung machine. It can simulate full lock-to-lock under extreme conditions. Ignacio ran our pump up to 1,600 pounds. A normal truck seldom sees more than 1,400 pounds. No pump leaves the shop without being fully bench tested.

The last step was to install it on the Ford bracket and attach the pulley, making sure the spacing lined up correctly with the serpentine belt. The new pump shaft had been machined for an exact fit to the Ford pulley.

Next we turned our attention to the gearbox. All critical components were Magnafluxed. Magnafluxing is an advanced procedure that uses strong magnetic fields to test the structural integrity of metals, especially iron and iron-based alloys. The procedure can determine even microscopic flaws in the surface structure of a variety of metal parts, a process that can detect even the slightest hairline crack in a sector shaft.

There were many more parts than we might imagine. The input shaft, valvebody, and rack piston were carefully inspected. The little recirculating balls that are fed into the input shaft were checked for size. Too small will create too much play in the steering. The assembled gearbox was manually tested and adjusted for the correct left and right pressure points and smoothness. On the hydraulic test bench, all fittings were double-checked for leaks under simulated extreme lock-to-lock turns.

We debated whether or not to install a ram-assist on our truck. Tom advised that the ram, which is attached where the steering stabilizer would normally go, adds about 100 percent turning power. This significantly reduces the stress on the gearbox, pump, and all the components of the system. It also does a superior job of absorbing shock. In our case, thanks to our 40.7-inch tires, the liability of a rock hitting the hydraulic cylinder was minimal. In the event the cylinder was damaged, it would be a simple matter of disconnecting the two feed lines from the gearbox and capping the left and right pressure ports.

| 29. A special tool was used to insert the seals in the housing.

As a final precaution, we installed a Boss Magnefine power steering filter. The unique design and patented process of the Magnefine, with its effective magnetic inline filter, removes 99 percent of hard-wearing ferrous metal particles (from sub-micron level and above), significantly reducing wear of internal components.

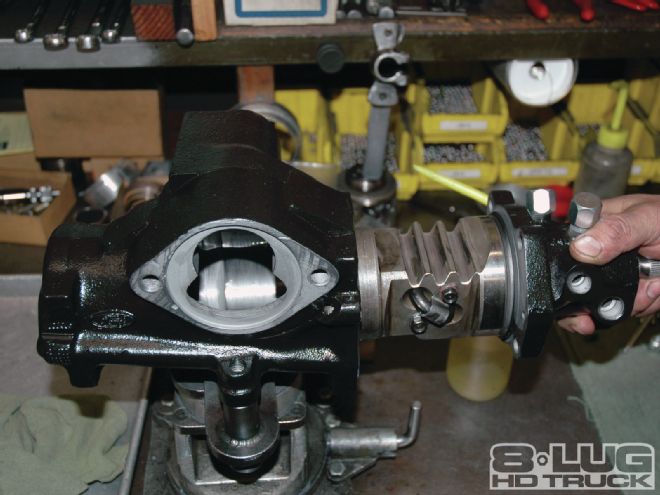

| 30. The big rack piston is the driving force when you move the steering wheel.

On the highway, the steering is tight and precise. Even at 65 mph on a flat and level road, the truck will track straight, hands-free, for a hundred yards or more. Following backroads on Utah’s Cathedral Loop in the Capital Reef National Park and driving up the Moki Dugway out of Valley of the Gods, lock-to-lock corners were smooth and easy.

On a three-year trip across Europe and Asia following dirt tracks over mountain passes and crossing unbridged rivers, there will be plenty of problems to worry about. Our steering won’t be one of them.

| 17. On the test machine, Ignacio Vertti ran our pump up to 1,600 pounds and checked its flow rate of 3.5 gpm. A normal truck seldom sees more than 1,400 pounds.

When the pump and new can were assembled, they were attached to a test bench to check for balance, proper flow rate, and leakage. The test bench looks like some kind of heart/lung machine. It can simulate full lock-to-lock under extreme conditions. Ignacio ran our pump up to 1,600 pounds. A normal truck seldom sees more than 1,400 pounds. No pump leaves the shop without being fully bench tested.

The last step was to install it on the Ford bracket and attach the pulley, making sure the spacing lined up correctly with the serpentine belt. The new pump shaft had been machined for an exact fit to the Ford pulley.

| 17. On the test machine, Ignacio Vertti ran our pump up to 1,600 pounds and checked its flow rate of 3.5 gpm. A normal truck seldom sees more than 1,400 pounds.

When the pump and new can were assembled, they were attached to a test bench to check for balance, proper flow rate, and leakage. The test bench looks like some kind of heart/lung machine. It can simulate full lock-to-lock under extreme conditions. Ignacio ran our pump up to 1,600 pounds. A normal truck seldom sees more than 1,400 pounds. No pump leaves the shop without being fully bench tested.

The last step was to install it on the Ford bracket and attach the pulley, making sure the spacing lined up correctly with the serpentine belt. The new pump shaft had been machined for an exact fit to the Ford pulley.

| 30. The big rack piston is the driving force when you move the steering wheel.

On the highway, the steering is tight and precise. Even at 65 mph on a flat and level road, the truck will track straight, hands-free, for a hundred yards or more. Following backroads on Utah’s Cathedral Loop in the Capital Reef National Park and driving up the Moki Dugway out of Valley of the Gods, lock-to-lock corners were smooth and easy.

On a three-year trip across Europe and Asia following dirt tracks over mountain passes and crossing unbridged rivers, there will be plenty of problems to worry about. Our steering won’t be one of them.

| 30. The big rack piston is the driving force when you move the steering wheel.

On the highway, the steering is tight and precise. Even at 65 mph on a flat and level road, the truck will track straight, hands-free, for a hundred yards or more. Following backroads on Utah’s Cathedral Loop in the Capital Reef National Park and driving up the Moki Dugway out of Valley of the Gods, lock-to-lock corners were smooth and easy.

On a three-year trip across Europe and Asia following dirt tracks over mountain passes and crossing unbridged rivers, there will be plenty of problems to worry about. Our steering won’t be one of them.