The progressive build of our ’07 Chevy 2500 Duramax diesel project truck was much like the average diesel owner might experience. We began with suspension upgrades and added a tuner, followed by intake and exhaust upgrades. Next came improved vehicle braking while towing. The goal of keeping EGT in check was accomplished with a larger, more efficient intercooler.

We reached a point when we needed to improve the durability and longevity of the Allison 1000 transmission. The Banks Power components that were added to the truck pushed it well beyond the Allison 1000’s estimated torque rating of 650 to 660 lb-ft for our vintage transmission. Incidentally, the newest version (on ’11 trucks) of the Allison 1000 can handle more than 765 lb-ft of torque. After careful consideration of our options (shift kit, torque converter, or complete rebuild of the Allison), we elected to have the capable hands of ATS Diesel Performance in Arvada, Colorado, do a complete rebuild of the Allison 1000.

| 01. ATS builds stout transmissions. We take an inside look at one.

The package selected for our truck was the LCT1000 6-Speed Stage 3 package, which includes an ATS-built Allison 1000 LCT1000 transmission, ATS Five Star Viskus Clutch Drive torque converter, ATS extra deep transmission pan, ATS Co-Pilot electronic transmission controller, and ATS billet flexplate. The rating for the Stage 3 package is 650 hp and 1,200 lb-ft of torque at the rear wheels. This package is backed by ATS’ industry-shattering 5-year or 500,000-mile warranty. One very impressive note about the warranty (should a problem arise) is the complementary removal and reinstallation of the transmission at the company headquarters in Colorado. To read more about the impressive transmission and torque converter warranty, please visit www.atsdiesel.com/warranty.

| 02. After the transmission was extracted, Jacob flushed the transmission cooler lines to ensure all contaminants were removed and verified the fluid was flowing through the cooler properly.

Our journey down the path to obtain a stronger, more reliable transmission and torque converter system begins in the capable hands of Jacob Looney, just one of the many competent installers at ATS. We were in awe watching this skilled mechanic at work. The speed and efficiency with which he performed his magic led us to think there were two mechanics tackling the task at hand.

Jacob wheeled the 350-pound transmission over to Rod Kuenning for disassembly. With our camera at the ready, Rod began what we thought was going to be a difficult and time-consuming process; after all, there are more than 120 bolts on the Allison 1000. (Without telling Rod, we noted the time he began the teardown.) During the process, Rod noted the slightly burned clutches and pointed out a few of the weak points in the transmission. He doesn’t just disassemble transmissions, he also performs failure analysis when one is returned for warranty work and notes the failures of OEM transmissions as well. This information is fed back to the engineering department so they can implement design changes to improve reliability and strength. A mere 11 minutes later, the entire thing was disassembled and put into the eco-friendly cleaning station. When we mentioned the time to Rod, he quipped, “Not my personal best, but it’ll do.”

| 03. Failure analysis is a critical component of the success of ATS Diesel’s products. Any failures noticed during a transmission’s disassembly are documented by Rod and passed along to the mechanical engineers to determine areas of improvement.

With the guts of the Allison 1000 skillfully extracted and cleaned, it was time to learn about the engineering behind the ATS enhancements that will make this transmission handle up to 1,000 lb-ft of torque. Clint and his team know that any transmission is only as good as its weakest link, and they have spent a considerable amount of time and money on research and development to perfect what they believe is the strongest, most reliable transmission for the money. Can they make them stronger? You bet, but at a considerably higher cost, and honestly, the average truck owner simply does not need 300M cryogenic-treated transmission shafts. However, if you’re interested, ATS can do that, too. In case you were wondering, 300M is a low-alloy, vacuum-melted steel of very high strength. It has a very good combination of strength, toughness, fatigue strength, and ductility. The mechanical engineers at ATS modeled the various transmission shafts and have identified the weak point in each one. This information is utilized to reinforce the weak areas for increased strength and reliability of its custom-built shafts.

| 04. It only took Rod 11 minutes to completely disassemble and inspect our Allison 1000 transmission.

Armed with the knowledge that doing any or all of the following will improve transmission performance, ATS Diesel Performance investigated the possibilities of improving the properties of the friction material and its adhesion characteristics, increasing a clutch’s surface area, increasing the number of clutches where applicable, and increasing clamping force when required. Rather than focusing on one area, owner Clint Cannon and his team addressed all of them on the Allison 1000.

| 08. In this photo, Rod was preparing the C1 clutches to be bonded to the proprietary ATS friction material.

All automatic transmissions will benefit from improved clutches and properly applied hydraulic pump line pressure. ATS Diesel Performance understands this need and has answered the call dutifully. Our ATS LCT-1000 Billet Transmission features some pretty cool underappreciated or misunderstood proprietary and patented technological innovations.

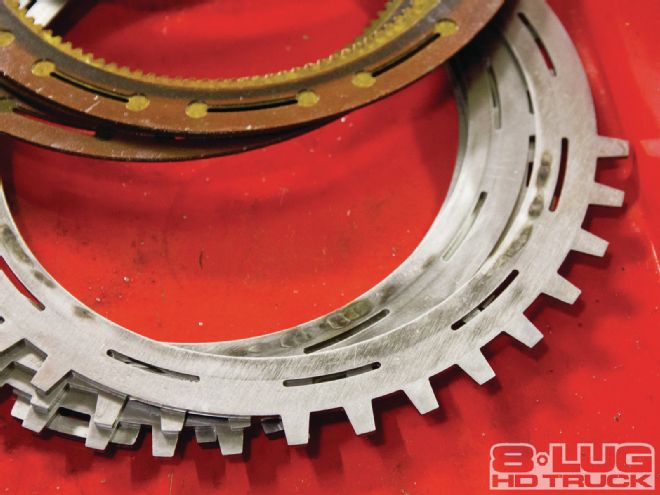

An automatic transmission is nothing without effective clutches and steels. The clutches are referred to as C1, C2, and so on, according to their placement in the transmission. A clutch is a flat, circular ring in the transmission that is coated with a friction material (which is heat-pressed onto the clutch) and used to transfer the torque from the driving gear to the various driven gears. The steels work hand in hand with the clutches (the steels are forced against the friction material on the clutches to transfer the torque).

A clutch is a clutch, right? Not hardly. With size and quantity equal, what sets the ATS parts apart from the OEM versions are the friction material and the glue that secure them to the face of the clutch. A typical transmission clutch friction material is paper. Yes, paper—but not paper like a magazine page. It’s a cellulose friction paper that begins as cotton or another cellulose fiber that is ground up with additives, such as flaked graphite or other material for thermal conductivity. The mixture is felted and saturated with a water- soluble binder (glue) so that it may be attached to the clutch material. Incredibly, this paper mache-type of concoction is able to transfer the engine’s torque and apply it to the truck’s axles.

| 09. After the secret hybrid glue is activated on ATS’ friction material, it is then heat- pressed onto the steel disc, forming an incredibly strong bond. This combination is far superior to the cellulose-based friction material bonded to the clutch with water-soluble glue used by the OEMs.

Clint set out to correct the deficiencies in paper clutches that use water-soluble glue for adhesion. In defense of the auto manufacturers, the paper/water-soluble glue is sufficient for the average automotive application, but Clint knows his diesel customers are anything but average. Using the info shown below as a guide, it took several iterations to find the correct balance of materials to formulate ATS’ proprietary friction material.

Desirable Properties for Friction Materials in a Transmission Clutch

- The materials in contact (clutch and steel) must have a high coefficient of friction (the force required to move sliding surfaces over each other, divided by the force holding them together)

- Friction value must be constant throughout a range of temperatures

- Must possess good thermal properties, high heat capacity, and good thermal conductivity

- Able to withstand moderate to high contact pressure

- Good shear strength to transfer friction forces

Without giving away the secret formula, we can report that the friction material is a balance of cellulose for friction properties: carbon to transfer the heat to the steel plate away from the friction material, carbon fiber strands for shear strength to prevent the friction material from tearing, and other special ingredients. After this mix is felted, proprietary hybrid glue (which is non-water-soluble) is applied to the back of the sheet. The ATS hybrid glue is similar to an epoxy that is activated by heat and another chemical, and it will not delaminate once it is bonded to the steel clutch. The friction material is cut to specification by ATS. Clint was not satisfied with stopping at creating his own friction material for transmissions and torque converters; he wanted to make even more improvements.

Examining the weak points in design and failures of the Allison 1000 clutches, many options were investigated for improvements.

| 10. To make room for the extra clutches, ATS machines down the C3 clutch backing plate.

To accomplish these upgrades, some of the stock internal components of the Allison 1000 required modification or a complete redesign. One cannot simply add clutches to a transmission and expect them to fit. Therefore, to accommodate the additional C1 and C2 clutches, the thickness of the P1 planetary drive flange was machined down to allow proper fitment of the drive’s snap ring. The C3 and C4 clutches and steels were redesigned completely. The C3 clutches suffer from inadequate oiling and have a tendency to fail prematurely. ATS moved the oiling passage from the face of the clutch to its inner diameter ring. This new design accomplishes two things: improved lubrication and increased friction area. Similar to the C1 and C2 clutches, the thickness of the C3 clutch backing plate was reduced to allow for the added C3 and C4 clutches.

| 17. The C3/C4 clutches are redesigned to omit the center oil passage. In addition, the number of clutches is increased, which adds 50 percent to the clutch surface area. The C3 backing plate was machined down to allow for the extra clutches.

With the clutch packs adequately improved with new friction material, increased effective surface area, and improved oiling, it was time to tackle the fluid dynamics. The oil pump receives a new main pressure regulator valve and spring, while the valvebody upgrades include a laser-cut separator plate and an extra fluid solenoid on the remote reverse pipe, which is controlled by ATS’ Co-Pilot electronic transmission controller. The Co-Pilot augmented with the hydraulic modifications allows for increased line pressure when demanded and improved shift calibration by remapping the shift points.

Component Failure Mode Stock Configuration ATS Improvements

C1 Clutch Pack Off-center apply piston, on-shifting clutch 6 clutches and steels 16 single-side clutches, effectively adding 10 times the surface area; converted to shifting clutch

C2 Clutch Pack Off-center apply piston 6 clutches and 7 steels 7 clutches and steels, 15 percent surface area improvement

C3/C4 Clutch Pack Oil passage reduces friction material surface area C3: 4 clutches and 3 steels; C4: 5 clutches and 4 steels Both receive 6 clutches and 5 steels; the clutches are redesigned to omit the center oiling areal which yields a 50 percent increase in surface area

C5 Clutch Pack OEM friction material 6 Clutches and 6 steels 6 clutches and 6 steels

To finish off the improvements to the Allison 1000, a significantly larger transmission oil pan was added. Heat is the number one killer of any transmission, so it was a no-brainer for the crew at ATS to design a larger-capacity oil pan. Its pan isn’t just larger than the OEM, it is specifically designed to transfer the heat out of the oil through conduction and convection cooling. This large-capacity pan will hold an astonishing 5 more quarts than the OEM pan. ATS tops it off with a magnetic oil drain plug.

| 18. The number of the C5 clutches remains the same, but the ATS versions (like all the other clutches) utilize ATS’ proprietary glue and friction material.

The ability for ATS to perform all the engineering and fabrication in-house allows for significantly tighter clearances and specifications during the transmission assembly. The tight quality control and attention to detail will result in a better-built, longer-lasting, and more-reliable transmission.

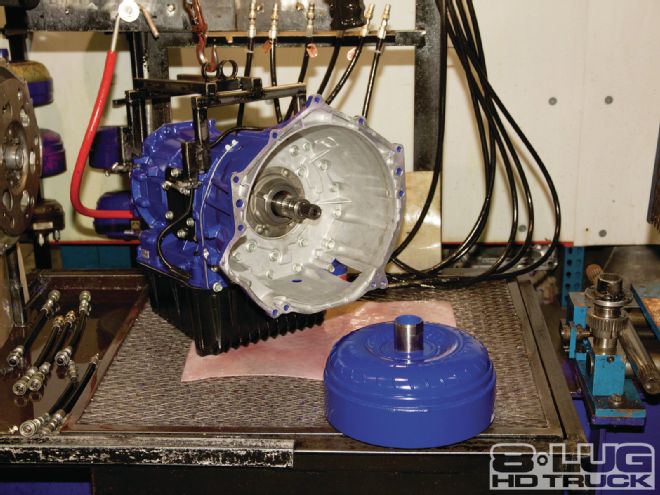

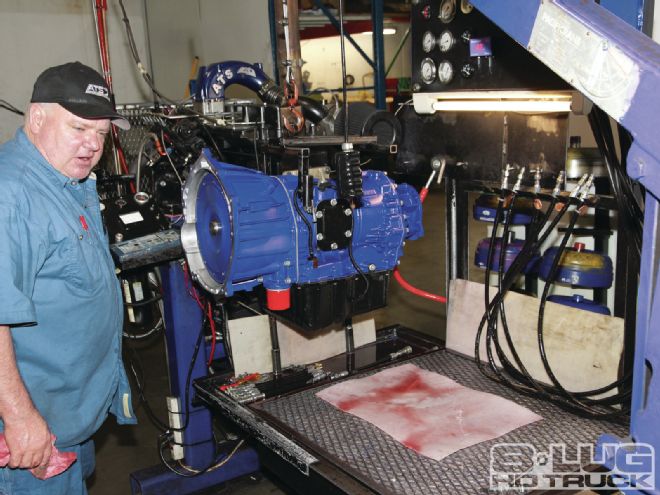

With a fresh battery installed in the camera, we were ready for Dave Oliver to assemble our transmission. Dave had everything laid out and ready for the assembly. If we thought Jacob or Rod were fast, we had seen nothing yet. This master mechanic could have assembled it blindfolded and still finish before most. Thankfully, Dave had to stop for a lunch break so we could recharge the camera battery. If you ever want to be humbled, spend a few hours with Dave talking about transmissions and automotive theory. As standard operating procedure, once Dave completed the assembly of the Allison 1000, it was wheeled over to Bob Wichmann to be put through its paces on one of the two purpose-built transmission dynamometers.

At the transmission dyno, Bob selected the ATS Five Star Viskus Clutch drive torque converter that would be mated to our transmission. The Five Star torque converter is yet another engineering marvel Clint has patented. Specific details of the Five Star will be featured in an upcoming issue. However, to pique your interest, the efficiency of the Five Star creates an additional 18 lb-ft of torque and was designed and tested to withhold more than 2,000 lb-ft of torque! Bob filled the torque converter and transmission with oil and circulated the oil throughout the system prior to firing up the 5.9L Cummins. The transmission dyno is a sophisticated piece of equipment, too. Bob is able to put the transmission through a full heat cycle, shift sequences, torque converter lockup, and load the transmission as if it were hauling a fully loaded trailer through the Rocky Mountains. This testing is performed on every transmission built by ATS—not just the one we saw installed.

| 19. The ATS Stage 3 package includes an enhanced main pressure regulator valve and spring, an additional solenoid, shift valve, new snap rings, and a new HD bearing.

While the rest of the crew was working on the transmission, Jacob had already installed the ATS Billet Flexplate and the Co-Pilot control module and cable harness. As expected, the transmission was installed without any issues.

Afterward, we road-tested the truck with Jacob. What a difference! The shifts were firm and smooth, and gone were the lags between shifts. Thanks to the added solenoid on the valvebody and commands from the Co-Pilot, line pressure was increased from 80 psi to 300 psi. And now that the clutches have increased surface area and improved friction material, gone are the days of worrying about burnt or slipping clutches.

| 26. After the pipe was correctly dissected, Dave removed the burs before assembling the two halves into the solenoid valve.

After the road test, the truck went back on the vehicle dyno to compare the before and after results. We witnessed steeper curve lines (indicating the improved shifting points as mapped by the Co-Pilot) and more holding power thanks to the added line pressure. Unfortunately, the files from the dyno were corrupted, so we cannot give you a good side-by-side comparison. Given the breadth of knowledge and expertise these guys have, we’ll take Clint at his word that the Allison LCT1000 6-Speed Stage 3 package will deliver an extra 25 hp and 51 lb-ft of torque to the rear wheels thanks to the improved efficiency of the ATS-built drivetrain.

ATS Diesel Performance is committed to delivering what the customer wants and needs for his truck. Clint Cannon’s Team USA and pro-U.S. manufacturing epitomizes the entrepreneurial spirit that makes our country so great. He began with an idea and theory to improve the aftermarket transmission segment. As a result, he has aligned himself with some phenomenal engineers and craftsmen who understand the theory of operation and are driven to invent, design, manufacture, and sell the world’s most innovative diesel truck performance products that are made in the United States.

| 27. Not only does the ATS deep transmission oil pan hold an extra 5 quarts of oil, it cools the oil more efficiently thanks to those fins on the inside of the pan.